CF/peek composite material with high fatigue strength and preparation method thereof

A fatigue strength and composite material technology, which is applied in the field of carbon fiber reinforced polyetheretherketone composite materials, can solve problems such as difficulty in realizing industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of the CF / PEEK composite material with high fatigue strength, the steps are as follows:

[0051] (1) Sinter 3K5 satin fabrics of CF T300 grade at 300°C for 180 minutes to decompose the original sizing agent on the surface;

[0052] (2) In a saturated water vapor environment with a relative humidity of 95.3%, microwave irradiation and ultraviolet light irradiation are carried out on CF simultaneously, and the product is recorded as ACF; the time of microwave irradiation is 30min, and the microwave frequency is 300MHz; the wavelength of ultraviolet light is irradiated 290nm, UV irradiance is 20W / m 2 ;

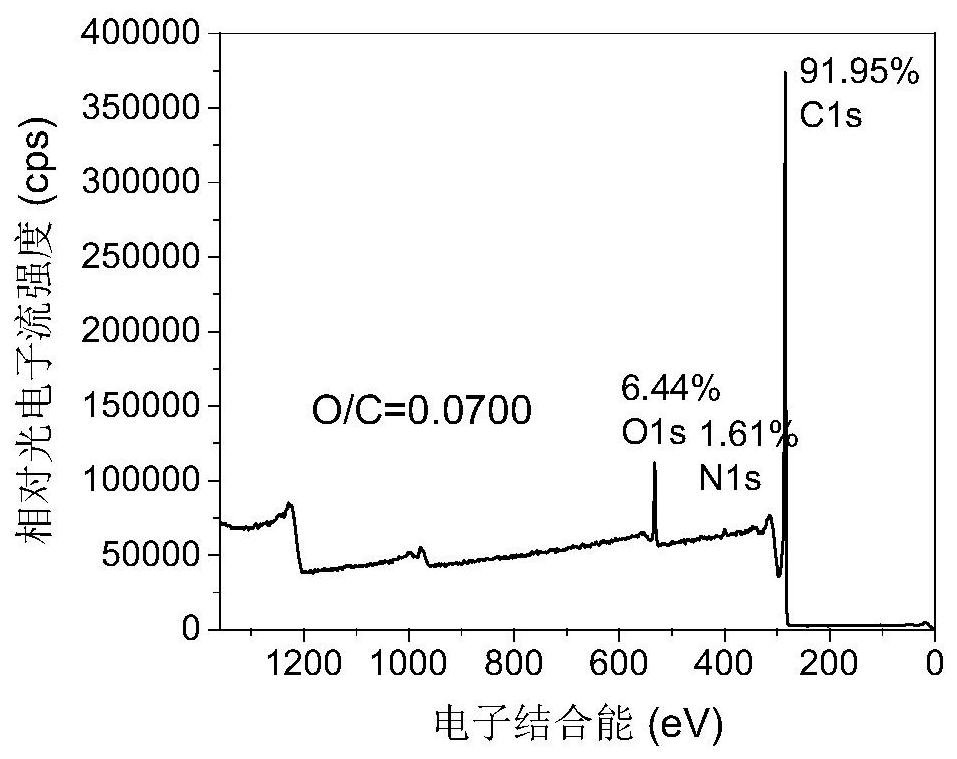

[0053] (3) Immerse the ACF in the polyetherimide / dichloromethane / carbon nanotube suspension for 180min, the weight average molecular weight of the polyetherimide is 51000, take it out and dry it until the water content is 0.48wt.%, to obtain the sizing Modified carbon fiber MCF, scanning electron microscope photos as Figure 4 Shown; In the polyet...

Embodiment 2

[0066] The preparation method of the CF / PEEK composite material with high fatigue strength, the steps are as follows:

[0067] (1) Sinter 3K5 satin fabrics of CF T300 grade at 350°C for 138min to decompose the original sizing agent on the surface;

[0068] (2) In a saturated water vapor environment with a relative humidity of 95.8%, CF is irradiated with microwaves and ultraviolet light at the same time, and the product is recorded as ACF; the time of microwave irradiation is 27min, and the microwave frequency is 820MHz; the wavelength of ultraviolet light is irradiated 299nm, UV irradiance is 50W / m 2 ;

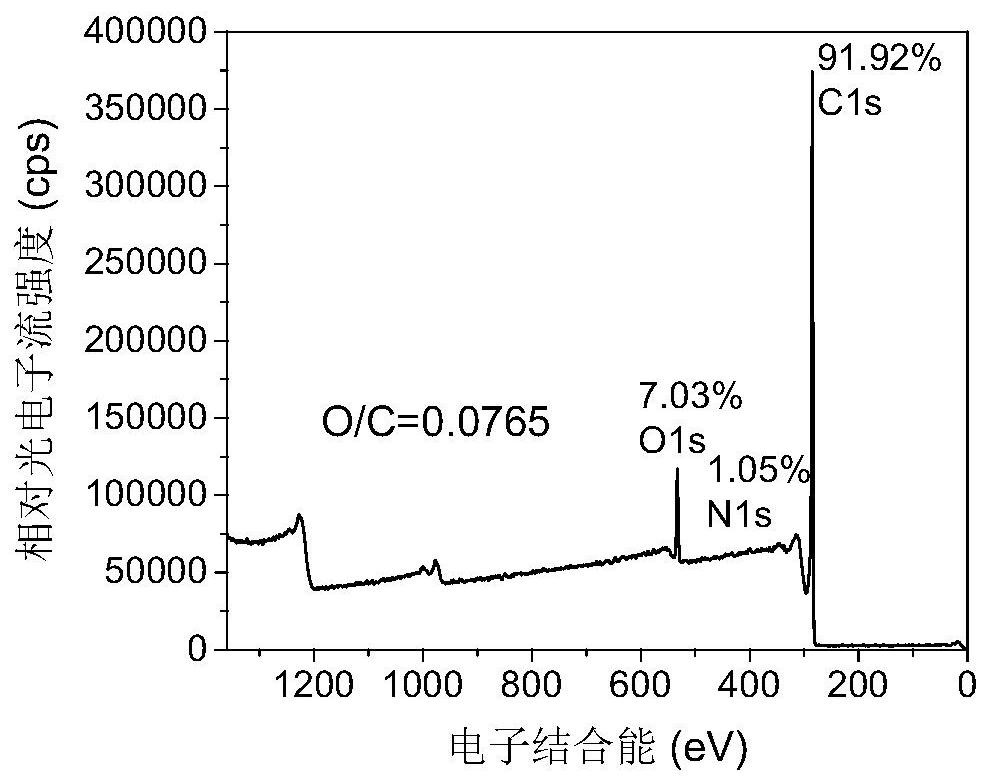

[0069] (3) Immerse the ACF in the polyetherimide / dichloromethane / carbon nanotube suspension for 175min, the weight average molecular weight of the polyetherimide is 55000, take it out and dry it until the water content is 0.45wt.%, to obtain the sizing Modified carbon fiber MCF; in the polyetherimide / methylene chloride / carbon nanotube suspension, the polyetherimide content ...

Embodiment 3

[0074] The preparation method of the CF / PEEK composite material with high fatigue strength, the steps are as follows:

[0075] (1) Sinter 5 pieces of satin fabric of T300 grade 3K of CF at 420°C for 5 minutes to decompose the original sizing agent on the surface;

[0076] (2) In a saturated water vapor environment with a relative humidity of 95.9%, CF is irradiated with microwaves and ultraviolet light at the same time, and the product is denoted as ACF; the time of microwave irradiation is 24min, and the microwave frequency is 1GHz; the wavelength of ultraviolet light is irradiated 305nm, UV irradiance is 35W / m 2 ;

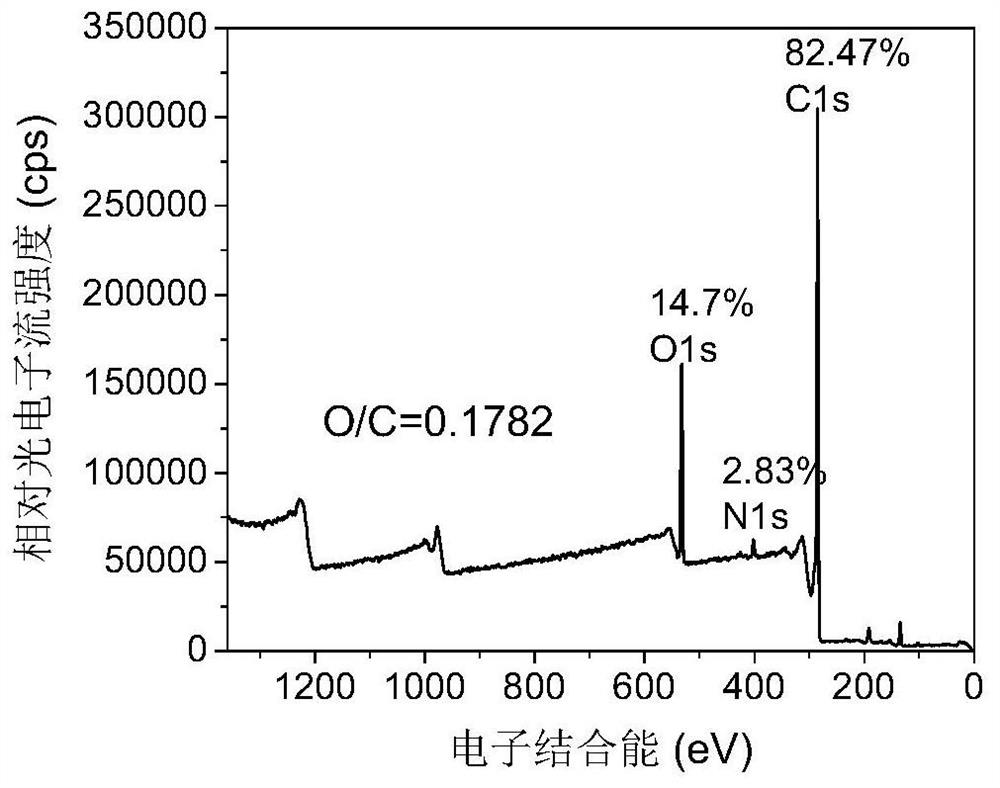

[0077] (3) Immerse the ACF in the polyetherimide / dichloromethane / carbon nanotube suspension for 142min, the weight average molecular weight of the polyetherimide is 59050, take it out and dry it until the water content is 0.42wt.%, to obtain the sizing Modified carbon fiber MCF; polyetherimide / dichloromethane / carbon nanotube suspension, polyetherimide content i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com