Antistatic recyclable PE film for powder packaging

An antistatic technology for packaging, applied in the field of packaging, can solve the problems of high dosage of non-ionic antistatic agent, difficulty in neutralizing the negative charge on the surface of PE, poor thermal stability, etc., achieve low thermal conductivity and inhibit decomposition , to promote the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

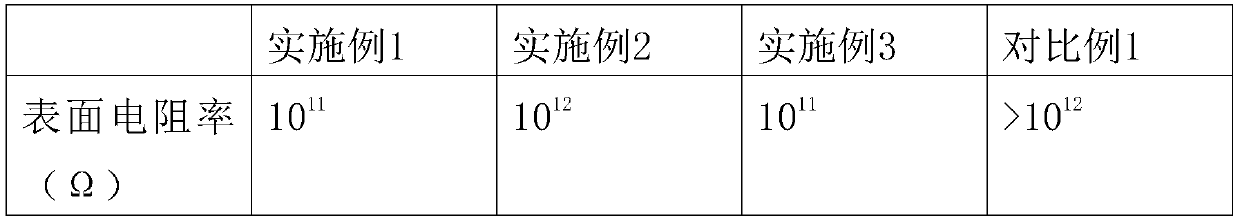

Examples

Embodiment 1

[0023] An antistatic recyclable PE packaging film for powder packaging is a three-layer co-extrusion blown film, which includes a PE surface layer, a PE middle layer and a PE heat-sealing layer laminated in sequence. Wherein, the PE surface layer is composed of raw materials in the following weight percentages: LLDPE 40%, HDPE 40%, LDPE 20%. The PE middle layer is composed of raw materials in the following weight percentages: LLDPE 40%, HDPE 30%, LDPE 30%. The PE heat-sealing layer is composed of the following raw materials in weight percentage: 55% of LLDPE, 40% of LDPE, and 5% of porous heat-insulating ceramic microspheres adsorbed with cationic antistatic agent.

[0024] Here, the preparation method of porous heat-insulating ceramic microspheres is: mix 1 g of water-soluble zirconium source, 1 g of porous polyglyceryl methacrylate / ethylene glycol dimethacrylate microspheres with an average particle size of 5 μm, and 6 ml of water, and ultrasonically After dispersing and so...

Embodiment 2

[0026]An antistatic recyclable PE packaging film for powder packaging is a three-layer co-extrusion blown film, which includes a PE surface layer, a PE middle layer and a PE heat-sealing layer laminated in sequence. Wherein, the PE surface layer is composed of raw materials in the following weight percentages: LLDPE 60%, HDPE 30%, LDPE 10%. The PE middle layer is composed of raw materials in the following weight percentages: LLDPE 60%, HDPE 20%, LDPE 20%. The PE heat-sealing layer is composed of the following raw materials in weight percentage: 69% of LLDPE, 30% of LDPE, and 1% of porous heat-insulating ceramic microspheres adsorbed with cationic antistatic agent.

[0027] Here, the preparation method of porous heat-insulating ceramic microspheres is to mix 6g of water-soluble zirconium source, 2g of porous polyglycerol methacrylate / ethylene glycol dimethacrylate microspheres with an average particle size of 5 μm and 10ml of water, and ultrasonically After dispersing and soak...

Embodiment 3

[0029] An antistatic recyclable PE packaging film for powder packaging is a three-layer co-extrusion blown film, which includes a PE surface layer, a PE middle layer and a PE heat-sealing layer laminated in sequence. Wherein, the PE surface layer is composed of raw materials in the following weight percentages: LLDPE 50%, HDPE 35%, LDPE 15%. The PE middle layer is composed of raw materials in the following weight percentages: LLDPE 55%, HDPE 22%, LDPE 23%. The PE heat-sealing layer is composed of the following raw materials in weight percentage: 65% of LLDPE, 31% of LDPE, and 4% of porous heat-insulating ceramic microspheres adsorbed with cationic antistatic agent.

[0030] Here, the preparation method of porous heat-insulating ceramic microspheres is to mix 2g of water-soluble zirconium source, 1.5g of porous polyglyceryl methacrylate / ethylene glycol dimethacrylate microspheres with an average particle diameter of 5 μm and 8ml of water, Ultrasonic dispersion, soaking for 1-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com