Plastic-wood composite material with high static bending, wear resistance and high and low temperature resistance and preparation method thereof

A wood-plastic composite material, high and low temperature resistance technology, applied in the anti-wear, high static warp, high and low temperature resistant type plastic wood composite material, the preparation field of the above composite material, can solve the problem of poor surface wear resistance and impact resistance, brittleness Large, insufficient toughness of the coating film, etc., to achieve the effect of outstanding high and low temperature resistance and high static bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

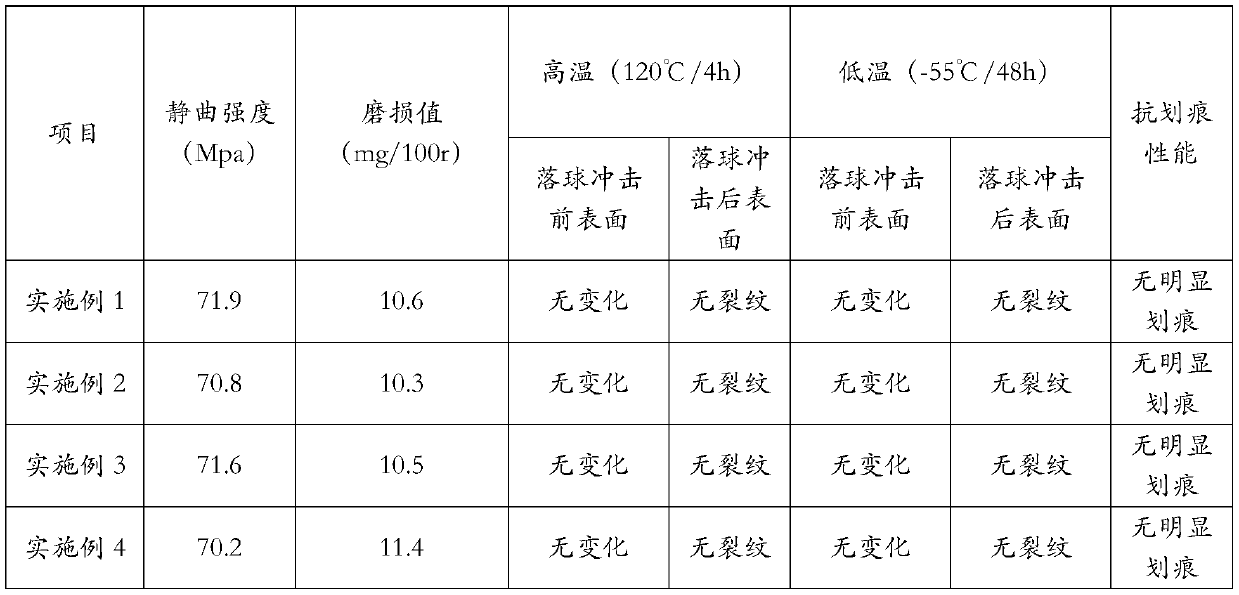

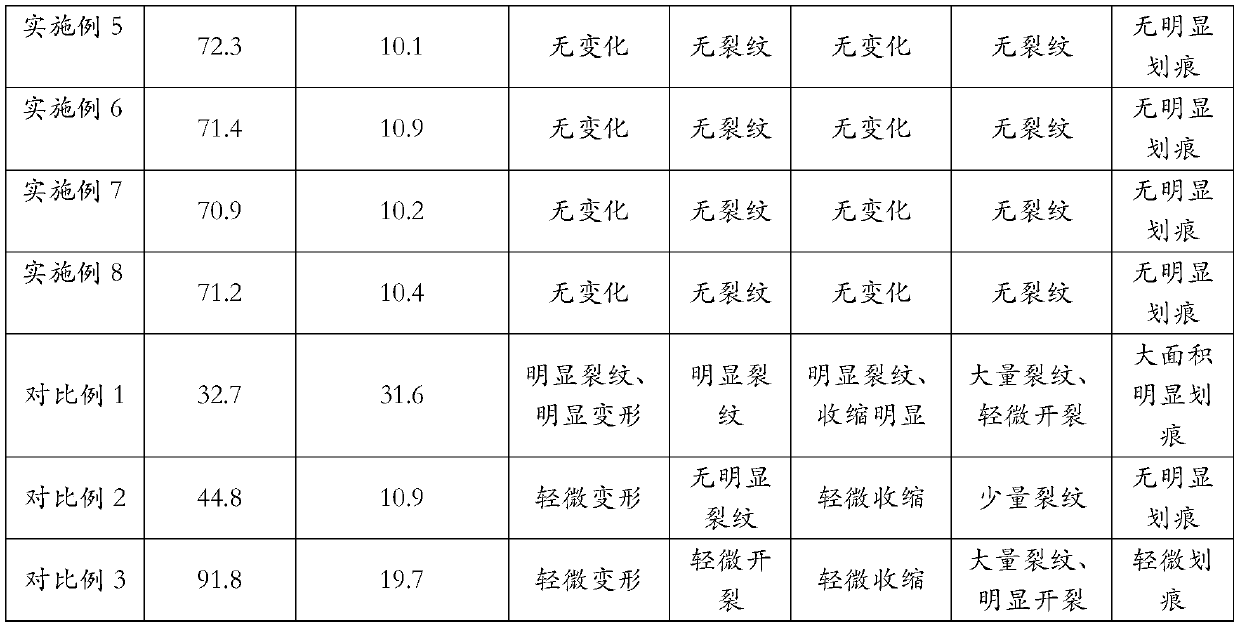

Examples

Embodiment 1

[0083] The preparation method of high static bending, anti-abrasion, high and low temperature resistant plastic wood composite material comprises the following steps:

[0084] (1) The preparation process of polybismaleimide modified wood flour is:

[0085] S1: Add 10 mol of 4,4'-diaminodiphenylmethane into N,N-dimethylformamide solvent, stir at 35°C to fully dissolve, then keep warm at 40°C, add 8 mol in 4 batches Anhydrous pyromellitic dianhydride, add 2mol in each batch, and each batch is separated by 10min. After all pyromellitic dianhydride is added, keep warm for 20min, then add 5mol maleic anhydride, and continue to keep warm for 4h. , obtain polyamic acid solution, be cooled to room temperature;

[0086] S2: Add 22 mol dehydrating agent anhydrous acetic anhydride and 0.5 mol catalyst triethylamine to the polyamic acid solution in S1, stir rapidly at room temperature for 5 minutes, then add wood flour, stir and mix at room temperature for 0.5 h, then heat at 40°C Fully...

Embodiment 2

[0097] The preparation method of high static bending, anti-abrasion, high and low temperature resistant plastic wood composite material comprises the following steps:

[0098] (1) Polybismaleimide modified wood flour, styrene-N-phenylmaleimide copolymer, 20% glass fiber reinforced high-density polyethylene, high wear-resistant nylon 66 resin, phase Compatible agent, antioxidant, coupling agent and other additives are mixed at room temperature and stirred evenly to obtain a premix;

[0099] (2) Extrude and granulate the above-mentioned premixed material through a twin-screw extruder to obtain plastic wood pellets. The process conditions are as follows: the barrel temperature is 270°C, and the screw speed is 350rpm;

[0100] (3) Grinding the obtained mixed pellets into a 20-mesh powder through a high-speed pulverizer, and then placing the powder in an oven at 190° C. for 0.5 hours of cross-linking and curing;

[0101] (4) putting the resin powder obtained in step (3) into a con...

Embodiment 3

[0104] The preparation method of high static bending, anti-abrasion, high and low temperature resistant plastic wood composite material comprises the following steps:

[0105] (1) Polybismaleimide modified wood flour, styrene-N-phenylmaleimide copolymer, 20% glass fiber reinforced high-density polyethylene, high wear-resistant nylon 66 resin, phase Compatible agent, antioxidant, coupling agent and other additives are mixed at room temperature and stirred evenly to obtain a premix;

[0106] (2) Extrude and granulate the above-mentioned premixed material through a twin-screw extruder to obtain plastic wood pellets. The process conditions are: the barrel temperature is 290°C, and the screw speed is 400rpm;

[0107] (3) Grinding the obtained mixed pellets into a 50-mesh powder through a high-speed pulverizer, and then placing the powder in an oven at 210°C for 1.5 hours of cross-linking and curing;

[0108] (4) Put the resin powder obtained in the step (3) into a conical twin-scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com