Special two-component solvent-free polyurethane adhesive for compounding aluminized film

A solvent-free polyurethane, two-component technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive additives, etc., can solve the problems of flammability, solvent residue, explosion, etc., to avoid the addition of toxic solvents, Effect of improving water resistance and strength, and increasing curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

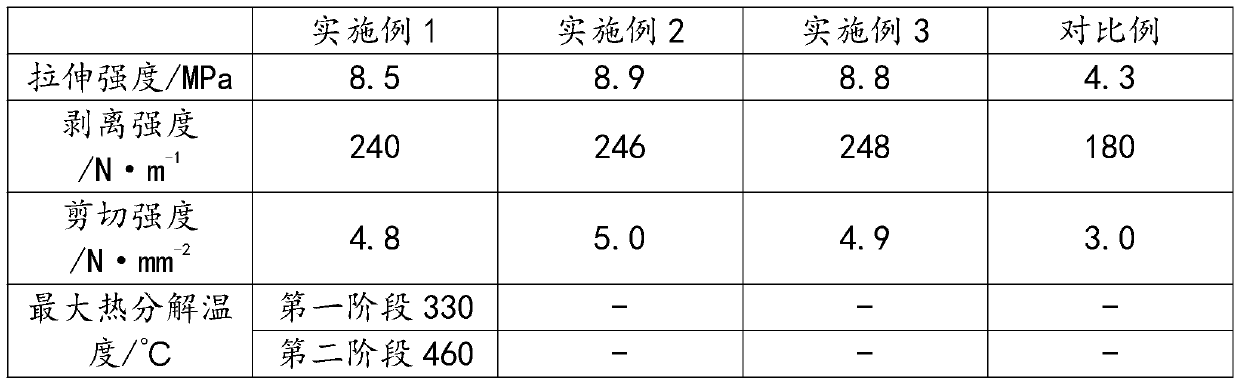

Examples

Embodiment 1

[0044] A two-component solvent-free polyurethane adhesive for aluminized film lamination, including component A and component B, the mass of component A and component B is 1:1.2;

[0045] Among them, component A is composed of the following components in parts by weight: 25 parts, 15 parts of polyester polyol, 1 part of modified nano-silica, 0.2 part of catalyst, and 0.1 part of antioxidant;

[0046] Mix polyester diol, modified nano silica, catalyst and antioxidant according to parts by weight, and stir evenly at 25°C to obtain component A;

[0047] Component B is polymethylene polyphenyl polyisocyanate;

[0048] Add component B to component A according to the proportion, and stir and mix at room temperature until a paste is formed to obtain a polyurethane adhesive.

Embodiment 2

[0050] A two-component solvent-free polyurethane adhesive for aluminized film lamination, including component A and component B, the mass of component A and component B is 1:1.4;

[0051] Among them, component A is composed of the following components in parts by weight: 30 parts and 18 parts of polyester polyol, 1.5 parts of modified nano-silica, 0.25 parts of catalyst, and 0.15 parts of antioxidant;

[0052] Mix polyester diol, modified nano silica, catalyst and antioxidant according to parts by weight, and stir evenly at 28°C to obtain component A;

[0053] Component B is polymethylene polyphenyl polyisocyanate;

[0054] Add component B to component A according to the proportion, and stir and mix at room temperature until a paste is formed to obtain a polyurethane adhesive.

Embodiment 3

[0056] A two-component solvent-free polyurethane adhesive for aluminized film lamination, including component A and component B, the mass of component A and component B is 1:1.5;

[0057] Among them, component A is composed of the following components, by weight: 35 parts of polyester polyol, 20 parts, 2 parts of modified nano-silica, 0.3 parts of catalyst, and 0.2 parts of antioxidant;

[0058] Mix polyester diol, modified nano silica, catalyst and antioxidant according to parts by weight, and stir evenly at 30°C to obtain component A;

[0059] Component B is polymethylene polyphenyl polyisocyanate;

[0060] Add component B to component A according to the proportion, and stir and mix at room temperature until a paste is formed to obtain a polyurethane adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com