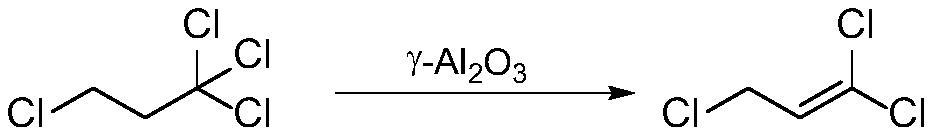

Gamma-aluminum oxide modified catalyst, preparation method thereof and application of gamma-aluminum oxide modified catalyst in synthesis of 1, 1, 3-trichloropropene

A technology of trichloropropene and alumina, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc. It can solve the problems of harsh reaction conditions and achieve simple preparation process , enlarged production, yield and purity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

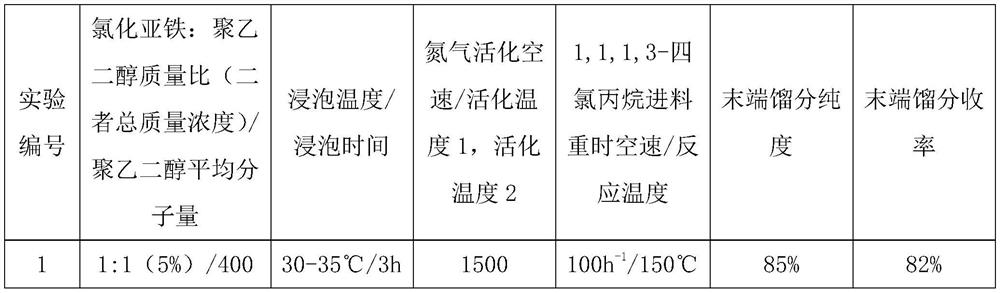

Examples

Embodiment 1

[0022] Catalyst preparation: Add 50g of γ-alumina to a 500mL beaker (100-200m 2 / g, content > 99.9%), add ferrous chloride (5.0g), the solution prepared by polyethylene glycol 400 (5.0g) and ethanol (90.0g), put into constant temperature water bath, rise to beaker internal temperature After reaching 40-45°C, continue to keep warm for 3h. Pour into a centrifuge for centrifugation, and rinse with 50 g of ethanol to obtain 56 g of modified γ-alumina.

[0023] 20 g of the above-mentioned modified catalyst was packed into a reaction tube (25 cm in length and 1.5 cm in diameter), and the parts on both sides of the tube not filled with catalyst were filled with glass beads, and the two ends were blocked with steel wire mesh. After the catalyst is loaded, nitrogen is introduced, and the space velocity is controlled at 1500h -1 , heating to raise the temperature inside the reaction tube to 60°C, maintain the temperature and nitrogen flow rate for activation for 1.0h, continue to incr...

Embodiment 2

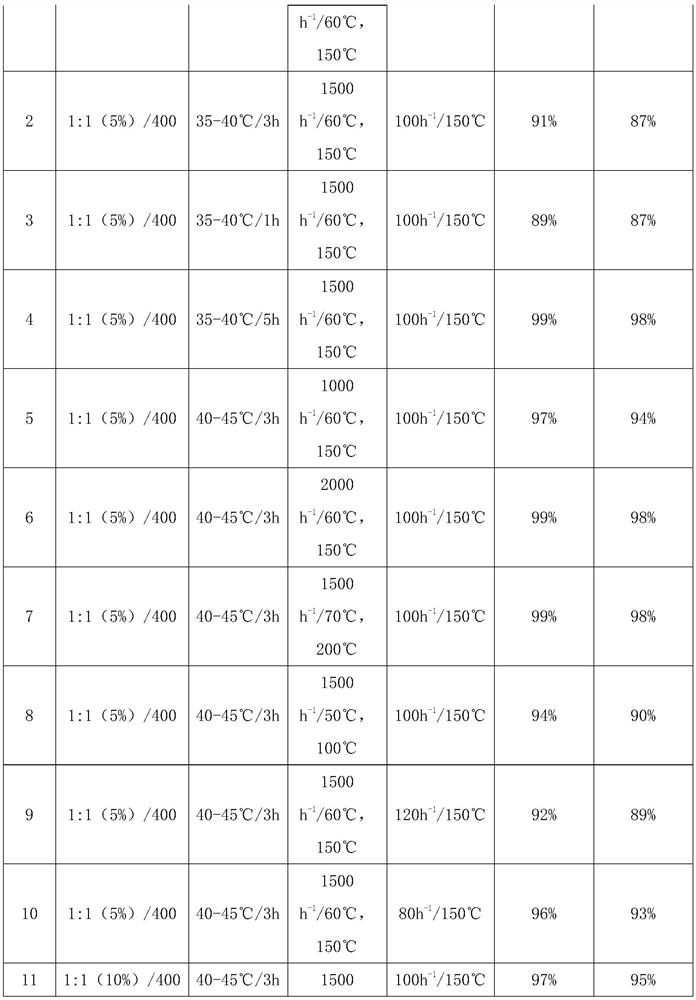

[0030] With reference to the operation of Example 1, the reaction conditions were changed to obtain the results in Table 2.

[0031] Table 2

[0032]

[0033]

[0034]

[0035] According to the analysis of the results in Table 2, it can be seen that ferrous chloride and polyethylene glycol 400 are loaded on the gamma-alumina carrier, and the yield of 1,1,3-trichloropropene and Purity > 90% effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com