Special cotton for graphene multifunctional blended mattress, sofa and car seat

A car seat and graphene technology, which is applied in the fields of special cotton for car seats, graphene multifunctional blended mattresses, and sofas, can solve the problems of complicated preparation steps, affecting functions, and high cost, so as to improve the dispersion effect and improve the product quality. Quality, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

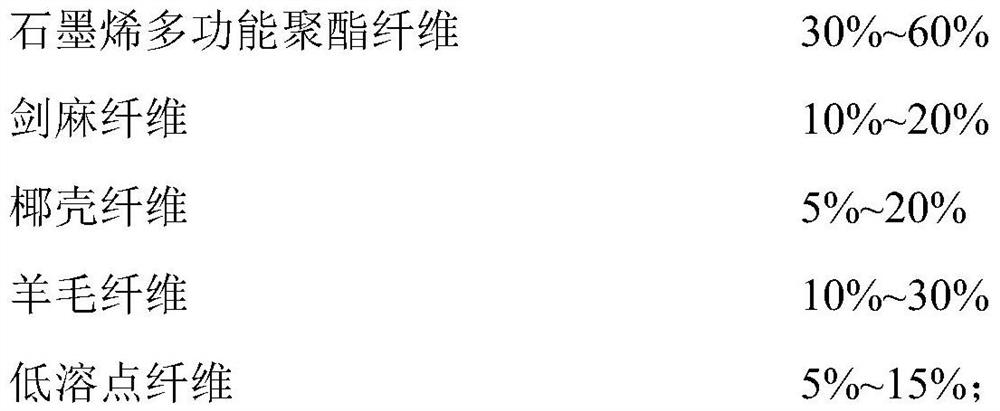

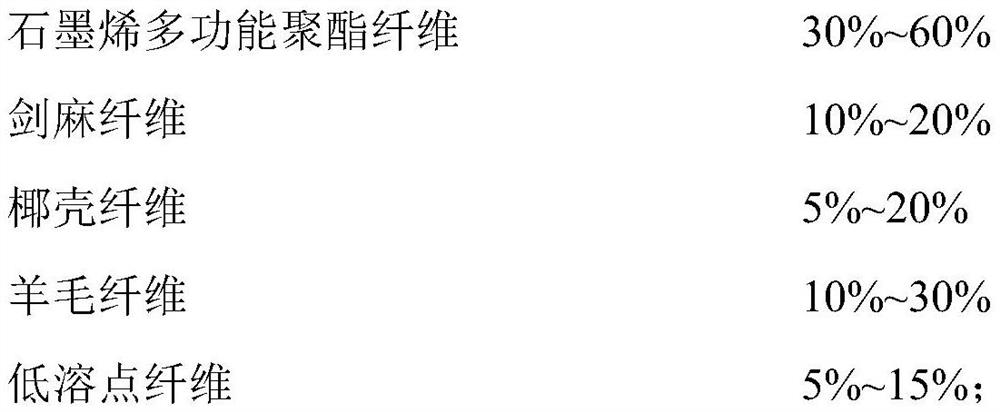

[0028] A kind of graphene multifunctional blended mattress of the present embodiment, sofa, special cotton for car seats are prepared by the following method:

[0029] (1) Preparation of graphene far-infrared polyester fiber:

[0030] Add 30 parts by weight of graphene and 70 parts by weight of nanometer far-infrared ceramic powder into a high-energy ball mill, add ethanol to disperse, then add 20 parts by weight of caustic agent sodium hydroxide for high-energy ball milling for 1 hour, and add hydrochloric acid to neutralize after ball milling. properties, washed with deionized water, and dried to obtain pretreated graphene and far-infrared nanoparticles (with a particle size of 50-600nm) by ball milling erosion and drilling. Get 34 parts by weight of ball mill erosion pretreated graphene and far-infrared nanoparticles and 65 parts by weight of polyester fiber chips to mix uniformly in a high-speed mixer, then add 0.5 parts by weight of heat stabilizer pentaerythritol stearat...

Embodiment 2

[0034] A kind of graphene multifunctional blended mattress of the present embodiment, sofa, special cotton for car seats are prepared by the following method:

[0035] (1) Preparation of graphene anion polyester fiber:

[0036] Add 20 parts by weight of graphene and 80 parts by weight of nano-tourmaline negative ion powder into a high-energy ball mill, add ethanol to disperse, then add 15 parts by weight of caustic agent sodium hydroxide for high-energy ball milling for 1 hour, and add hydrochloric acid to neutralize to medium after ball milling is completed. properties, washed with deionized water, and dried to obtain pretreated graphene and anion nanoparticles (with a particle size of 50 to 600 nm) that were eroded and drilled by ball milling. Get 24 parts by weight of ball-milling erosion pretreated graphene and negative ion nanoparticles and 75 parts by weight of polyester fiber chips to mix uniformly in a high-speed mixer, then add 1 part by weight of heat stabilizer pent...

Embodiment 3

[0040] A kind of graphene multifunctional blended mattress of the present embodiment, sofa, special cotton for car seats are prepared by the following method:

[0041] (1) Preparation of graphene magnetic polyester fiber:

[0042] Add 40 parts by weight of graphene and 60 parts by weight of magnetite nanopowder into a high-energy ball mill, add ethanol to disperse, then add 10 parts by weight of caustic agent sodium hydroxide for high-energy ball milling for 2 hours, and add hydrochloric acid to neutralize after ball milling. properties, washed with deionized water, and dried to obtain graphene and magnetic nanoparticles pretreated by ball milling erosion and drilling. Get 29.5 parts by weight of ball-milling erosion pretreated graphene and magnetic nanoparticles and 70 parts by weight of polyester fiber slices and mix uniformly in a high-speed mixer, then add 0.5 parts by weight of heat stabilizer pentaerythritol stearate, and then mix the mixture Extrude with a twin-screw e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com