Seal oil microcapsule and preparation method thereof

A technology of seal oil and microcapsules, which is applied in the field of medicine and chemical industry, can solve the problems of seal oil oxidation and decomposition quality, low digestion and absorption rate of wall materials, shorten shelf life, etc., achieve good nutritional and medical value, improve absorption rate, and extend shelf life period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

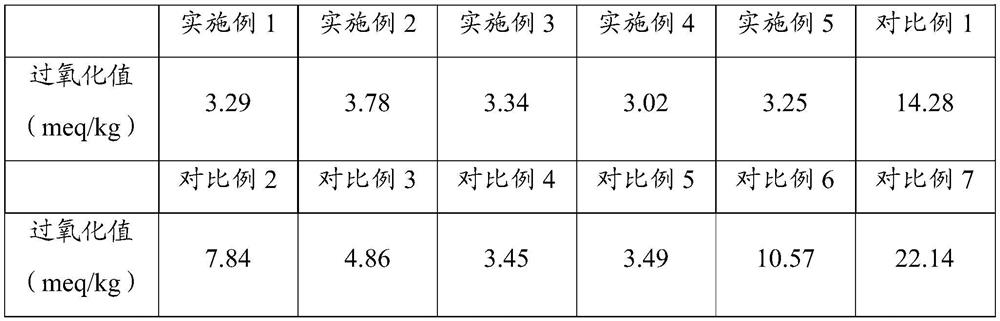

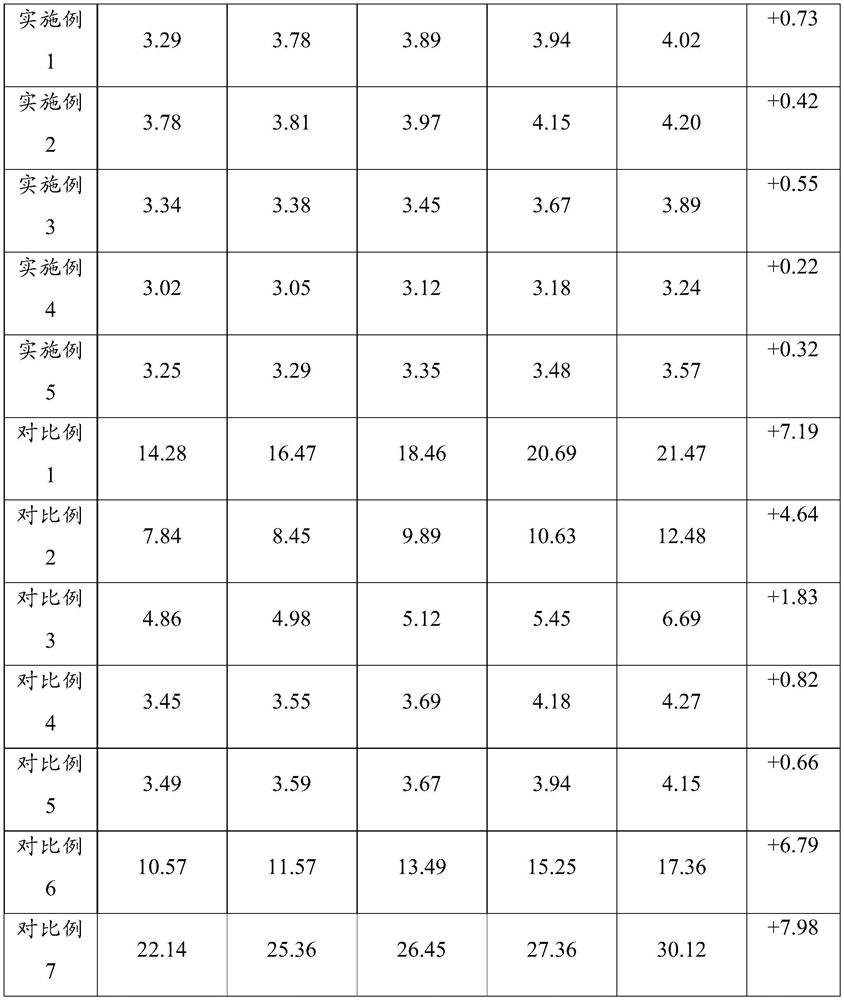

Examples

preparation example Construction

[0014] The preparation method of the seal oil microcapsule provided by the embodiment of the present invention adopts sodium alginate, sodium caseinate, calcium lactate, maltodextrin, modified soybean protein isolate and slow-release calcium hydroxide powder as embedding materials, and the The purified seal oil is embedded layer by layer to form multi-shell microcapsules with a high embedding rate, which can well isolate the seal oil from the air and avoid its oxidative deterioration during processing, transportation, and consumption. It prolongs its shelf life; and compared with the traditional spray drying method, the temperature is lower, so the quality of seal oil can be better guaranteed, and the production cost is saved; in addition, the addition of slow-release calcium hydroxide powder can improve the The effect of microcapsule products being digested and absorbed by the human body, thereby improving the absorption rate of seal oil by the human body, so that the seal oil...

Embodiment 1

[0046] The preparation technology of the seal oil microcapsules of embodiment 1 is as follows:

[0047] The subcutaneous fat tissue excised from the anatomical tissue of the seal is immediately frozen, and then the frozen subcutaneous fat tissue is taken out and cut into pieces, and then the cut subcutaneous fat tissue is placed in a twister at a temperature of 0°C. Crush and grind in a meat machine, and apply mechanical pressure to squeeze the oil out of the fat tissue, centrifuge at 3500rpm for 15 minutes, collect the oil—the crude extract of seal oil, and then place the crude extract of seal oil at an operating pressure of 2Pa, The temperature is 100°C and vacuum distillation is carried out to obtain purified seal oil.

[0048] The purified seal oil was dispersed in a compound solution of sodium alginate and sodium caseinate 10 times its volume, and homogenized at 800 r / min for 10 min to obtain seal oil microcapsules. Among them, the compound solution of sodium alginate an...

Embodiment 2

[0052] The preparation technology of the seal oil microcapsules of embodiment 2 is as follows:

[0053] The subcutaneous fat tissue excised from the anatomical tissue of the seal is immediately frozen, and then the frozen subcutaneous fat tissue is taken out and cut into pieces, and then the cut subcutaneous fat tissue is placed in a twister at a temperature of 5°C. Crush and grind in a meat machine, apply mechanical pressure to squeeze the oil out of the fat tissue, centrifuge at 4000rpm for 10min, collect the oil—the crude extract of seal oil, and then place the crude extract of seal oil at an operating pressure of 8Pa, The temperature is 60° C. and vacuum distillation is carried out to obtain purified seal oil.

[0054] The purified seal oil was dispersed in a compound solution of sodium alginate and sodium caseinate three times its volume, and homogenized at 1000 r / min for 5 minutes to obtain seal oil microcapsules. Among them, the compound solution of sodium alginate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com