Preparation method of lithium bis (fluorosulfonyl) imide

A technology of lithium bisfluorosulfonyl imide and bisfluorosulfonyl imide salt, which is applied in the field of preparation of lithium bisfluorosulfonyl imide, can solve the problem of high residual chloride ion and acetate, harsh process conditions and poor product quality. drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention provides a kind of preparation method of lithium bisfluorosulfonyl imide, comprising the following steps:

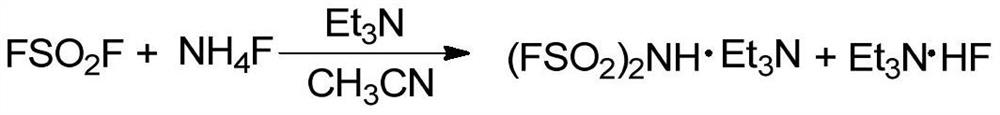

[0014] (1) In the presence of an ammonia source, an organic solvent, a fluoride salt and an initial amount of sulfuryl fluoride, while slowly introducing an organic base, continue to feed a surplus of sulfuryl fluoride until the end of the reaction, and the reaction solution is directly distilled under reduced pressure Afterwards, the intermediate bisfluorosulfonyl imide salt is obtained;

[0015] The method of the invention comprises the steps of introducing ammonia source, organic solvent, fluoride salt and sulfuryl fluoride into the reaction vessel.

[0016] The ammonia source may be a conventional ammonia source in the art. In an example of the present invention, the ammonia source is selected from ammonia gas, ammonium fluoride, and ammonia in acetonitrile solution, preferably ammonium fluoride.

[0017] The amount of the ammonia source introd...

Embodiment 1

[0050] Add 14.8 g of ammonium fluoride and 300 g of acetonitrile into a 1000 ml round bottom flask equipped with a stirrer, an air inlet, a constant pressure dropping funnel, and a thermometer, and the dropping funnel is preloaded with 161.6 g of triethylamine. Seal the system, cool to 10°C, vacuumize to 0.09MPa, and then inject sulfuryl fluoride gas to return to normal pressure. Triethylamine was added dropwise within 1 h. At the same time, sulfuryl fluoride was continuously introduced to the calculated amount of 82 g, and the reaction was completed after stirring for 14 hours. The reaction liquid is distilled under high vacuum and reduced pressure, and after recovering acetonitrile, triethylamine and triethylamine hydrofluoric acid salt, difluorosulfonimide triethylamine is obtained.

[0051] Add 54 g of acetonitrile and 12 g of lithium oxide powder to the above bisfluorosulfonimide triethylamine salt, and stir at room temperature for 4 h. After filtration, the filtrate wa...

Embodiment 2

[0053] Add 14.8 g of ammonium fluoride and 300 g of acetonitrile into a 1000 ml round bottom flask equipped with a stirrer, an air inlet, a constant pressure dropping funnel, and a thermometer, and the dropping funnel is preloaded with 114.6 g of tetramethylpropylenediamine. Seal the system, cool to 10°C, vacuumize to 0.09MPa, and then inject sulfuryl fluoride gas to return to normal pressure. Triethylamine was added dropwise within 1 h. Sulfuryl fluoride was continuously fed to 82 g, and it took 13 hours to complete the reaction. The reaction solution is distilled under high vacuum and reduced pressure to recover acetonitrile, triethylamine and hydrogen fluoride tetramethylpropylenediamine salt to obtain bisfluorosulfonimide tetramethylpropylenediamine salt.

[0054] Add 80 g of acetonitrile and 12 g of lithium oxide powder to the above bisfluorosulfonimide tetramethylpropanediamine salt, and stir at room temperature for 5 h. Filtration, precipitation and concentration of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com