A kind of preparation method of antibacterial and high temperature resistant copolyester

A technology of copolyester and high temperature resistance, which is applied in the field of preparation of antibacterial and high temperature resistant copolyester, can solve problems such as safety and stability, long-term antibacterial effect, impact on transparency, high intrinsic viscosity, etc., and meet broad market demand and promotion Application value, excellent antibacterial performance and high temperature resistance, effect of excellent antibacterial performance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of antibacterial and high temperature resistant copolyester, comprising the following steps:

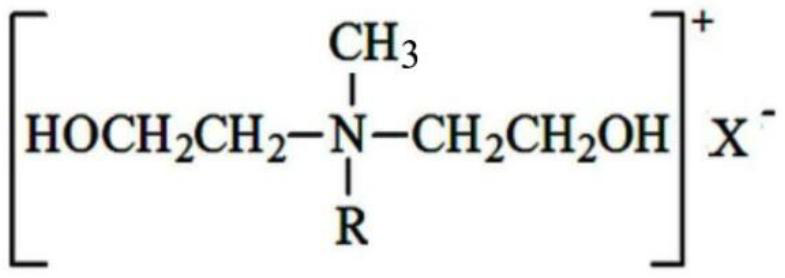

[0036] (1) Add dihydric alcohol, aromatic dibasic carboxylic acid and catalyst into the reaction device, and carry out esterification reaction at 250°C under the action of protective gas, the reaction time is 5h, and the reaction process pressure is 0.1-0.2MPa; wherein, The molar ratio of dihydric alcohol to aromatic dibasic carboxylic acid is 1.3:1, the dosage of catalyst is 0.1% of the total mass of dihydric alcohol and aromatic dibasic acid in the reaction system, and the dihydric alcohol is ethylene glycol, isosorbide and The mixture obtained by mixing dihydroxyquaternary ammonium salts in a molar ratio of 10:0.5:1, the aromatic dibasic acid is a mixture obtained by mixing terephthalic acid and terephthalic acid in a molar ratio of 5:1; the catalyst is Antimony trioxide; the structural formula of the dihydroxy quaternary ammonium salt is as follows:

...

Embodiment 2

[0043] The content of embodiment 2 is basically the same as that of embodiment 1, and the difference lies in:

[0044]The bishydroxy quaternary ammonium salt is prepared by the quaternization reaction of N-methyldiethanolamine and bromotetradecane. In the structural formula of the bishydroxy quaternary ammonium salt, R is tetradecyl, and X is Br.

Embodiment 3

[0046] The content of embodiment 3 is basically the same as that of embodiment 1, and the difference lies in:

[0047] The bishydroxy quaternary ammonium salt is prepared by the quaternization reaction of N-methyldiethanolamine and bromohexadecane. In the structural formula of the bishydroxy quaternary ammonium salt, R is hexadecyl, and X is Br.

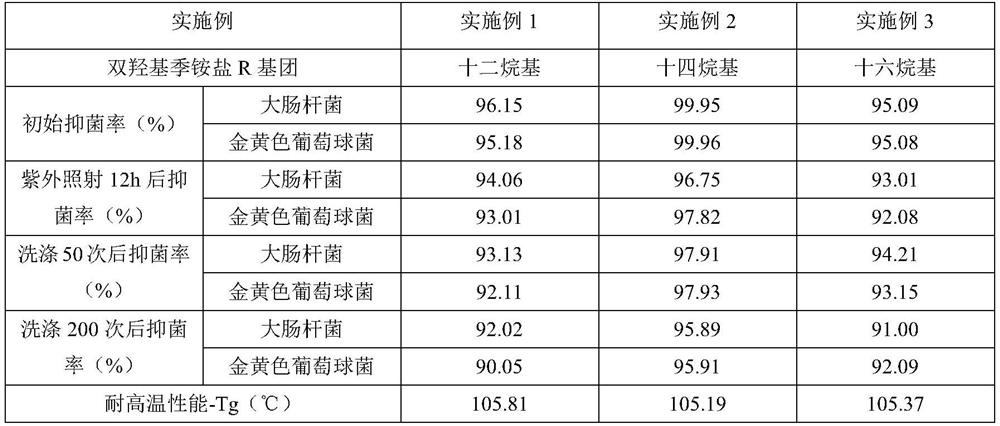

[0048] Table 1 Influence of different dihydroxy quaternary ammonium salts on the properties of polyester products

[0049]

[0050] It can be seen from Table 1 that the antibacterial properties of the prepared antibacterial and high temperature resistant copolyesters are significantly different due to the different R groups in the structural formula of the bishydroxy quaternary ammonium salt; when R in the structural formula of the bishydroxy quaternary ammonium salt is tetradecyl, the The antibacterial and high temperature resistant copolyester products can still achieve more than 95% antibacterial rate to Escherichia coli and St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com