Method for resolving optical isomers by electrodialysis technology

An optical isomer and electrodialysis technology, applied in the biological field, can solve the problems of recrystallization and purification, low yield and high cost, and achieve the effect of reducing production cost, improving yield and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]

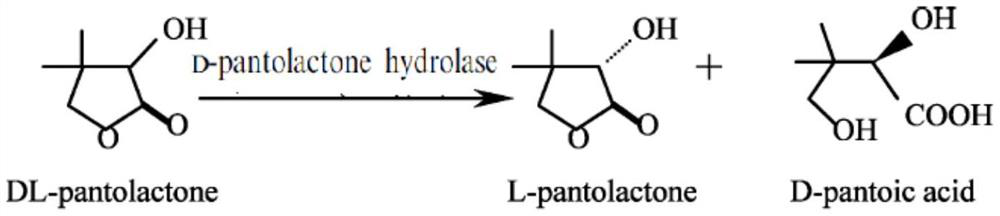

[0053] 1. Preparation of enzyme conversion solution: 2L system, add 600g of racemic pantotolactone, add 300g of immobilized cells containing D-pantotolactone hydrolase, pH7.0&30℃, 200rpm mechanical stirring, 15N NH 3 .H 2 O titration maintains a pH value of 7.0 and reacts for 3 hours;

[0054] 2. Pretreatment of the enzyme conversion solution: first filter with filter cloth, then filter with a 0.2μm microfiltration membrane, and then filter with a 50KD ultrafiltration membrane;

[0055] 3. Electrodialysis separation: use homogeneous membrane membrane stack B (size: 10*30cm; number of membrane pairs: 5 pairs), pump the ultrafiltrate supernatant into the electrodialysis desalination chamber, put 2L pure water in the concentration chamber, adjust The flow rate makes the pressure of the three chambers equal, and the constant pressure is 10V until the conductivity of the desalination chamber is less than 100μs / cm;

[0056] Pump the clear liquid from the concentration ...

Embodiment 2

[0060]

[0061] 1. Preparation of enzyme conversion liquid: 3L system, add 900g of racemic pantotolactone, add 90g of cells containing D-pantotolactone hydrolase, pH7.0&30℃, 200rpm mechanical stirring, 15NNH 3 .H 2 O titration maintains a pH value of 7.0 and reacts for 5 hours;

[0062] 2. Pretreatment of the enzyme conversion solution: first centrifuge with a butterfly centrifuge, then filter with a 0.4μm microfiltration membrane, and then filter with a 20KD ultrafiltration membrane;

[0063] 3. Electrodialysis separation: use the heterogeneous membrane membrane stack Z (size: 10*20cm; number of membrane pairs: 10 pairs), pump the ultrafiltrate supernatant into the electrodialysis desalination chamber, put 3L pure water in the concentration chamber, adjust The flow rate makes the pressure of the concentrating chamber three times that of the desalination chamber, and operates at a constant pressure of 25V until the conductivity of the desalination chamber is <100μs / cm;

...

Embodiment 3

[0070]

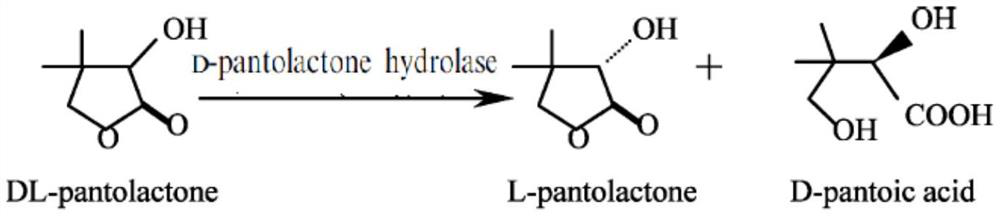

[0071] 1. Preparation of enzyme conversion solution: 1L system, add 20ml 3-cyclohexene-1-methyl carboxylate, add 10g Novozyme435 lipase, pH7.5&35℃, 200rpm mechanical stirring, 1N NaOH titration to maintain the pH value of 7.5, react 5h;

[0072] 2. Pretreatment of the enzyme conversion solution: filter with filter paper first, and then filter with a 0.4 μm microfiltration membrane;

[0073] 3. Electrodialysis separation: use homogeneous membrane membrane stack S (size: 10*20cm; number of membrane pairs: 10 pairs), pump the ultrafiltrate supernatant into the electrodialysis desalination chamber, put 1L pure water in the concentration chamber, adjust The flow rate makes the pressure of the three chambers equal, and the constant pressure is 14V until the conductivity of the desalination chamber drops to <100μs / cm;

[0074] Pump the clear liquid from the concentration chamber into the desalination chamber of the second-stage electrodialysis device, put 1L of pure wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com