Iodine-loaded titanium alloy implant with functions of resisting bacteria and promoting osteogenic differentiation and mineralization, and preparation method of iodine-loaded titanium alloy implant

A titanium alloy and implant technology, which is applied in the field of iodine-loaded titanium alloy implants and its preparation, can solve the problems of strict electrolyte preparation conditions and high cost of electroplating process equipment, and achieve significant osteogenic differentiation and mineralization. Promote the formation of calcium and phosphate mineralization layer and increase the effect of iodine loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

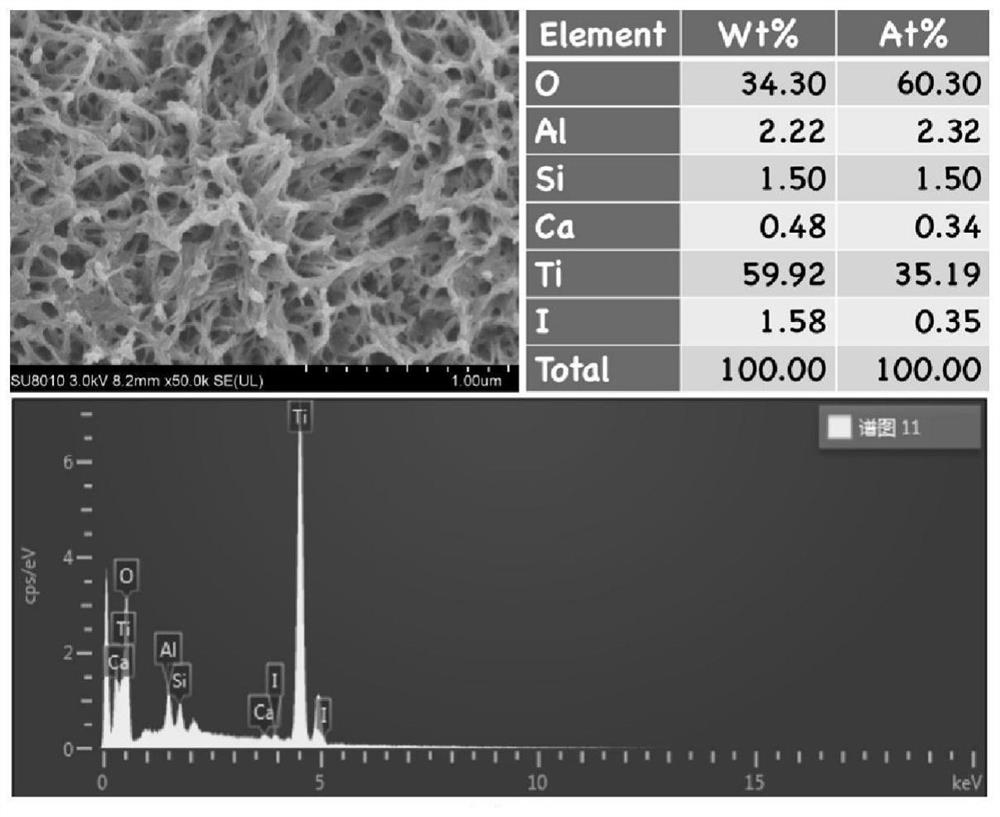

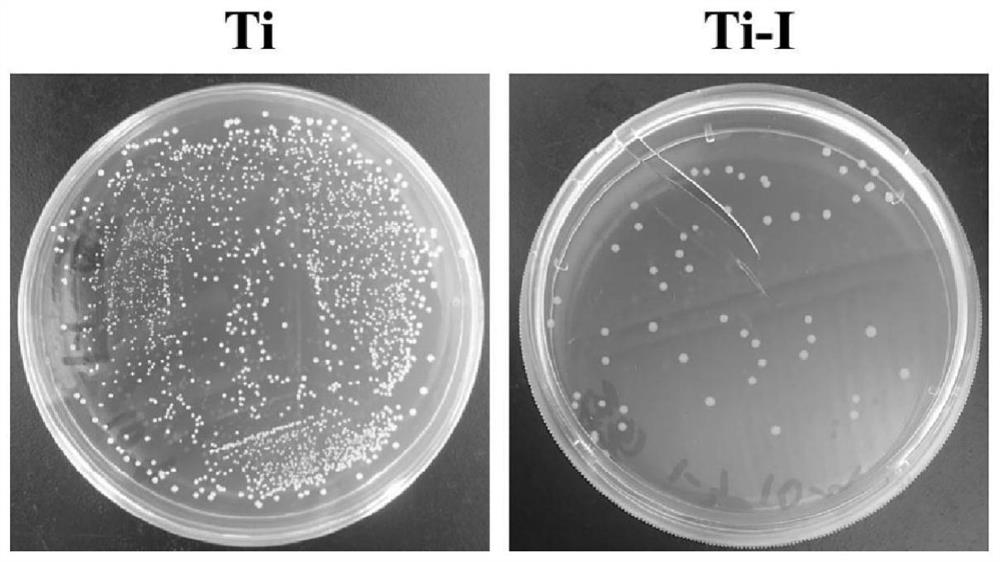

[0031] Preparation of Example 1 Iodine-loaded Titanium Alloy Implant (1)

[0032] 1. Titanium sheet surface modified polydopamine (Ti-PDA)

[0033] First, the titanium alloy Ti6AL4V (Zhejiang Kehui Medical Co., Ltd.) was immersed in a 5M NaOH solution, and reacted at 80° C. for 18 h under continuous magnetic stirring. The titanium sheet was taken out and ultrasonically cleaned with deionized water for 3 times, each time for 5 min, and dried in a fume hood. Then the titanium sheet was immersed in 2 mg / ml dopamine Tris-HCl (pH=8.5) solution, reacted at room temperature for 12 hours, ultrasonically cleaned three times with deionized water, and dried in a fume hood.

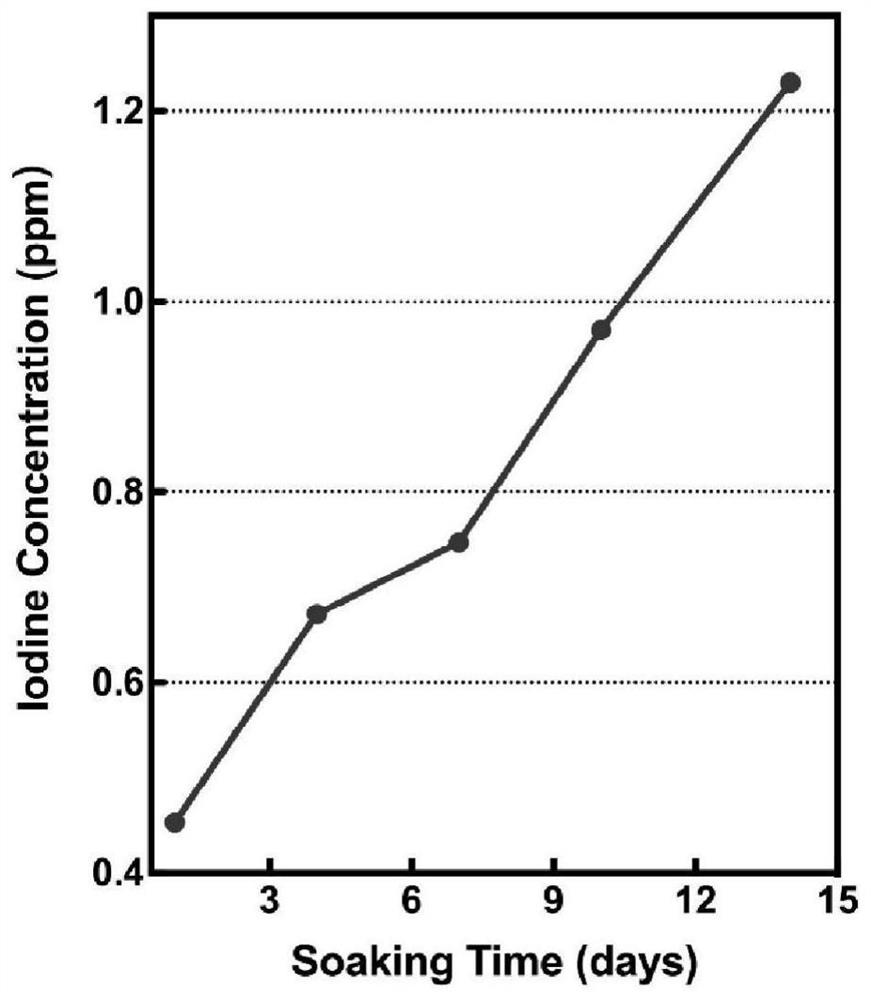

[0034] 2. Covalently bonded iodine (Ti-I) on the surface of titanium sheet

[0035] Use 0.1M potassium iodide solution as solvent to prepare 3% povidone iodine / potassium iodide (PVP-I 2 / KI) solution, the state of magnetic stirring was continued at room temperature for 30 min. Subsequent immersion of Ti-PDA in PV...

Embodiment 2

[0052] Embodiment 2 Preparation of the iodine-loaded titanium alloy implant of the present invention (two)

[0053] 1. Titanium sheet surface modified polydopamine (Ti-PDA)

[0054] First, the titanium alloy Ti6AL4V (Zhejiang Kehui Medical Co., Ltd.) was immersed in a 5M NaOH solution, and reacted at 80° C. for 10 h under continuous magnetic stirring. The titanium sheet was taken out and ultrasonically cleaned with deionized water for 3 times, each time for 10 min, and dried in a fume hood. Then the titanium sheet was immersed in 2 mg / ml dopamine Tris-HCl (pH=9) solution, reacted at room temperature for 10 h, ultrasonically cleaned 3 times with deionized water, and dried in a fume hood.

[0055] 2. Covalently bonded iodine (Ti-I) on the surface of titanium sheet

[0056] Use 0.1M potassium iodide solution as solvent to prepare 5% povidone iodine / potassium iodide (PVP-I 2 / KI) solution, the state of magnetic stirring was continued for 1 h at room temperature. Subsequent imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com