Copper slag treatment method, unfired water permeable material and manufacturing method of unfired water permeable material

A technology of processing method and manufacturing method, applied in the field of metallurgy, can solve problems such as high cost and complex process, and achieve the effect of low cost, simple process, and reduction of defects such as cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

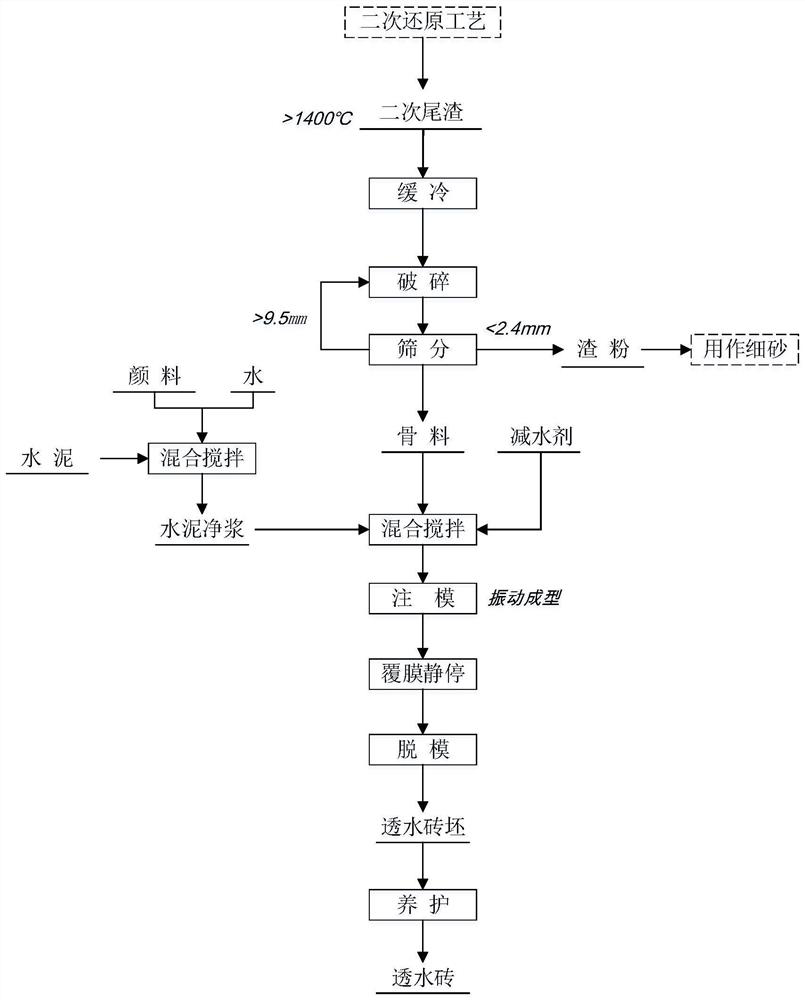

[0046] Pour the copper slag tailings (temperature 1420°C) into the slag pit, cover and keep warm for 12 hours to cool it to 800°C, and the cooling rate between 650°C and 1100°C is 20°C / min.

[0047] Then use a bucket machine to dig out and crush the copper slag tailings, and screen to obtain tailings with a particle size of 3-4.75 mm, which will be stored as fine aggregate for later use.

[0048] Pour 42.5 grade ordinary Portland cement and water into the concrete mixer and mix for 2 minutes. After forming a uniform slurry, add the above fine aggregate to the mixer and mix for 3 minutes. During the period, according to the fluidity of the mixture, add a certain amount of The amount of water reducer continued to stir for 1 to 2 minutes. The total ingredients are aggregate by weight: cement: water = 12:4:1.

[0049] After the mixture is evenly stirred, pour it into the inside and the size of the oil film is 200×100×60mm 3 Then put the mold on the vibrating platform and vibrate...

Embodiment 2

[0051] Pour the secondary smelted copper slag tailings (temperature 1380°C) into the slag bag, and cool it down to 760°C after natural cooling for 24 hours. The cooling rate between 650°C and 1100°C is 12°C / min .

[0052] Then the copper slag tailings are crushed, and the sieved tailings aggregates with a particle size of 5-10 mm are stored for later use.

[0053] Pour 42.5 grade slag cement, water, and red iron oxide into the concrete mixer and stir for 2 minutes. After forming a uniform slurry, add coarse aggregate to the mixer and stir for 3 minutes. During the period, according to the fluidity of the mixture, add a certain amount of The amount of water reducer continued to stir for 1 to 2 minutes. The total ingredients are calculated in parts by weight as aggregate: cement: water: red iron oxide = 20:5:1:0.05.

[0054] After the mixture is evenly stirred, pour it into the inside and the size of the oil film is 200×100×60mm 3 Then put the mold on the vibrating platform a...

Embodiment 3

[0056] Pour the secondary smelted copper slag tailings (temperature 1490°C) into the slag basin, and let it cool down to 820°C after natural cooling for 15 hours. The cooling rate between 650°C and 1100°C is 25°C / min .

[0057] Then, the copper slag tailings are crushed and screened to obtain fine aggregates with a particle size of 2.4-4.75 mm and coarse aggregates with a particle size of 4.76-10 mm, which are stored separately for later use.

[0058] Pour 42.5-grade composite Portland cement, water, and iron oxide yellow into the concrete mixer and stir for 2 minutes. After forming a uniform slurry, add fine aggregate to the mixer and stir for 3 minutes. During the period, according to the fluidity of the mixture, Then add the water reducer and continue to stir for 1-2 minutes to obtain a yellow mixture. The total ingredients are calculated in parts by weight as aggregate: cement: water: yellow iron oxide = 16:5:1:0.07.

[0059] Pour 42.5-grade composite Portland cement and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com