An Unsteady State Oil and Gas Recovery System

An oil and gas recovery system and unsteady state technology, which is applied in the recovery of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oil, etc., can solve problems such as oil and gas freezing, affecting the normal operation of heat exchangers, etc., to ensure safety and eliminate explosion risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

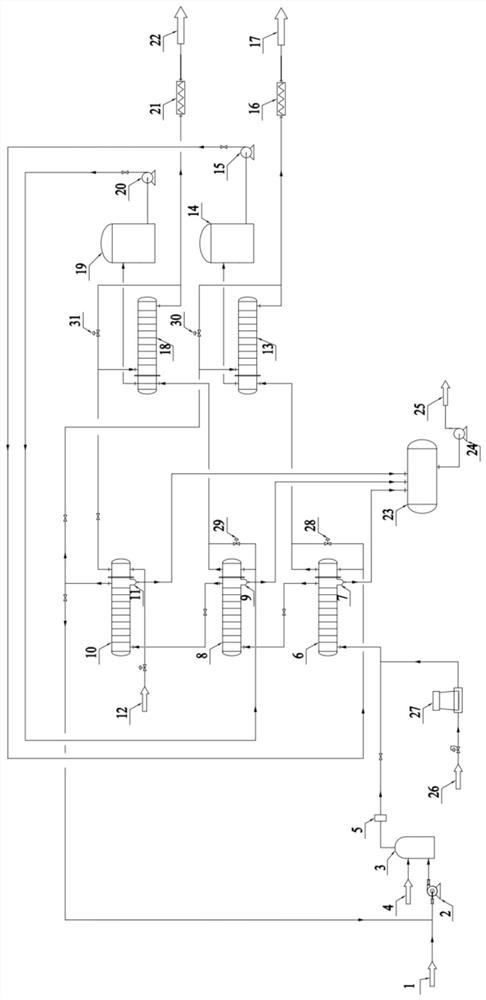

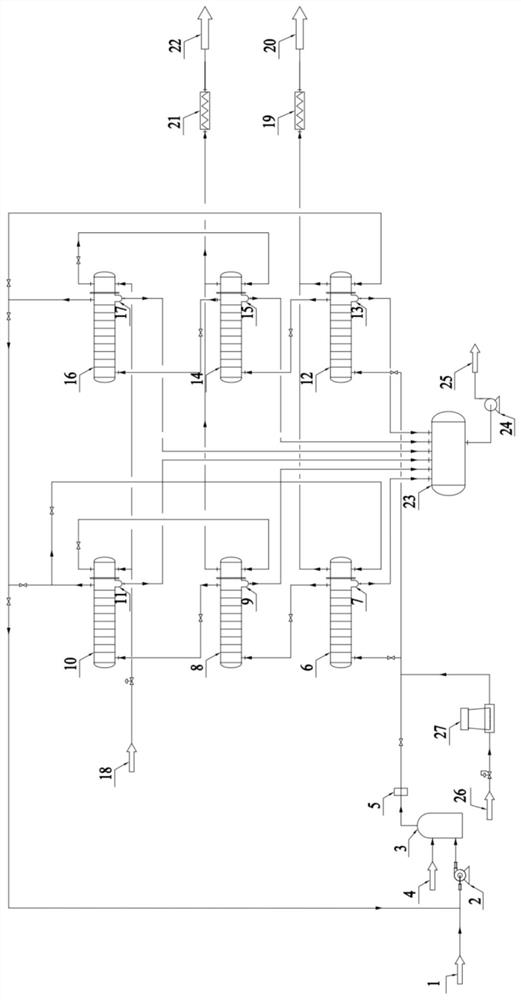

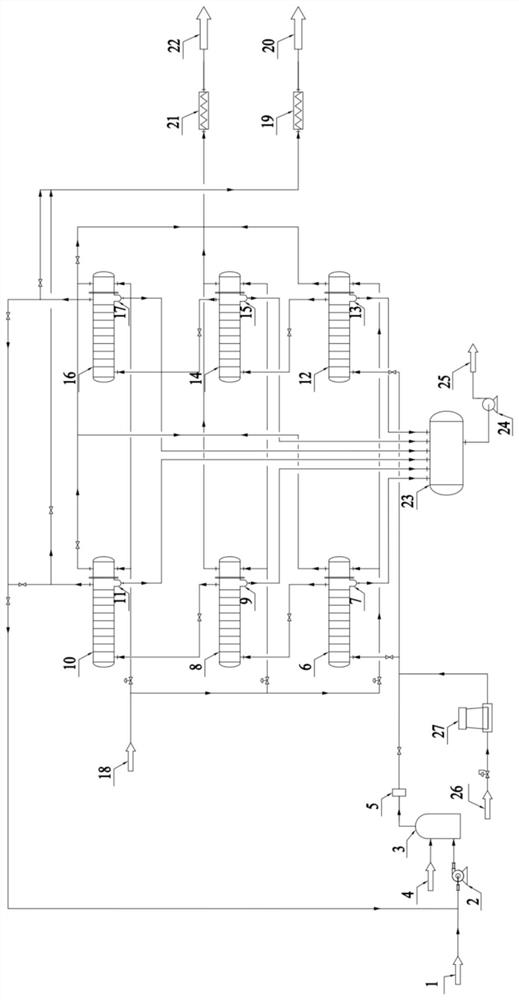

[0042] Provide an unsteady state oil and gas recovery system, including air intake system, safety system, primary condensing system, secondary condensing system, cryogenic heat exchange system, primary ethylene glycol cooling system, secondary ethylene glycol cooling system, Ethylene glycol storage and delivery system, low temperature oil and gas heating system, low temperature nitrogen heating system, liquid nitrogen delivery and adjustment system, condensate recovery and delivery system and defrosting system;

[0043] The air intake system includes an oil and gas input pipeline 1 and a fan 2 connected in sequence, the safety system includes a nitrogen dilution pipeline 4, a buffer tank 3 and an oxygen concentration analyzer 5 connected in sequence, and the primary condensing system includes a sequentially connected A primary condensation heat exchanger 6 and a primary gas-liquid separator 7, the secondary condensation system includes a secondary condensation heat exchanger 8 ...

Embodiment 2

[0059] Such as figure 1 As shown, the system flow of this embodiment is the same as that of Embodiment 1.

[0060] The oil and gas in this embodiment comes from the tail gas of a C4 oil product tank farm loading in a petrochemical plant, and the oil and gas treatment capacity is 500m 3 / h, after testing, the total non-methane hydrocarbon content in oil and gas is about 50g / m 3 , and contains a certain amount of water vapor. After the oil gas 1 is collected, it is sent to the buffer tank 3 through the fan 2. Since the oxygen content in oil gas 1 is about 21%, there is a risk of explosion, so nitrogen needs to be added for dilution. Nitrogen 4 is also sent to the buffer tank 3, and the oil gas and nitrogen gas are fully mixed in the buffer tank and then discharged. Use the oxygen concentration analyzer 5 to measure the oxygen content in the mixed oil and gas, and control the flow rate of dilute nitrogen to ensure that the oxygen content is lower than 8 %, the amount of dilut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com