Composite additive for alcohol gasoline, and preparation method thereof

A technology for compounding additives and gasoline, which is applied in the field of gasoline additives, can solve the problems of ineffective solution of methanol gasoline in the presence of water layer, affecting the rapid development of alcohol gasoline, and adding a large amount of emulsifying water-melting agent, etc., and achieves low price. , The effect of improving power value and utilization rate and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

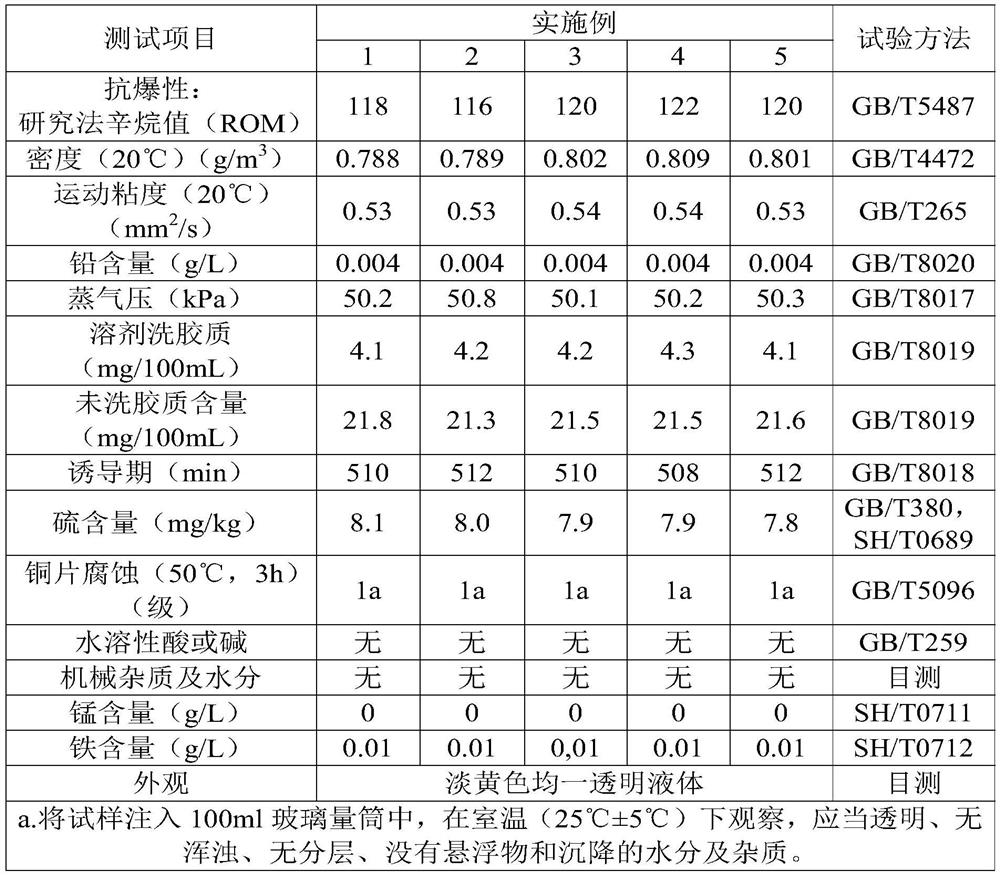

Examples

Embodiment 1

[0026] A compound additive for alcohol gasoline

[0027] Prepared from the following raw materials in parts by weight: 12.5g ethanol, 3.5g ethyl malonate, 13.0g n-octanol, 4.5g isobutane, 6.5g unsymmetrical dimethylhydrazine, 8.5g diisopropyl ether, cyclic Hexanol 10.0g, butylene oxide 2.8g, ammonium n-hexanoate (N-dodecylglucose) 1.2g, tert-butanol 2.8g, methylcyclopentadiene manganese tricarbonyl 0.8g, tert-butyl carbonate 2.2 g. 1.3 g of ethylene glycol monobutyl ether.

[0028] The preparation method is as follows:

[0029] Step 1, the weight parts of ethanol, ethyl malonate, n-octanol and isobutane were mixed and stirred at a rate of 220 rpm for 5 minutes to obtain a mixture A;

[0030] Step 2, mixing the unsymmetrical dimethylhydrazine, diisopropyl ether, cyclohexanol and butylene oxide in the parts by weight, and stirring at a rate of 180 rpm for 10 minutes to obtain a mixture B;

[0031] Step 3, the n-hexanoic acid (N-dodecylglucose) ammonium, tert-butanol, methylcy...

Embodiment 2

[0034] A compound additive for alcohol gasoline

[0035] Prepared from the following raw materials in parts by weight: 32.0g ethanol, 8.0g ethyl malonate, 22.0g n-octanol, 10.5g isobutane, 12.5g unsymmetrical dimethylhydrazine, 10.0g diisopropyl ether, cyclic Hexanol 12.0g, butylene oxide 4.6g, ammonium n-hexanoate (N-dodecylglucose) 1.8g, tert-butanol 3.8g, methylcyclopentadiene manganese tricarbonyl 1.4g, tert-butyl carbonate 2.6 g, 3.0 g of ethylene glycol monobutyl ether.

[0036] The preparation method is as follows:

[0037] Step 1. Mix the ethanol, ethyl malonate, n-octanol and isobutane in the parts by weight, and stir at a rate of 340 rpm for 15 minutes to obtain a mixture A;

[0038] Step 2, mixing the unsymmetrical dimethylhydrazine, diisopropyl ether, cyclohexanol and butylene oxide in the parts by weight, and stirring at a rate of 240 rpm for 15 minutes to obtain a mixture B;

[0039] Step 3, the n-hexanoic acid (N-dodecylglucose) ammonium, tert-butanol, methyl...

Embodiment 3

[0042] A compound additive for alcohol gasoline

[0043]Prepared from the following raw materials in parts by weight: 14.5g ethanol, 4.5g ethyl malonate, 15.0g n-octanol, 5.5g isobutane, 7.5g unsymmetrical dimethylhydrazine, 8.8g diisopropyl ether, cyclic Hexanol 10.5g, butylene oxide 3.0g, ammonium n-hexanoate (N-dodecylglucose) 1.3g, tert-butanol 3.0g, methylcyclopentadiene manganese tricarbonyl 1.0g, tert-butyl carbonate 2.3 g. 1.5 g of ethylene glycol monobutyl ether.

[0044] The preparation method is as follows:

[0045] Step 1, the weight parts of ethanol, ethyl malonate, n-octanol and isobutane were mixed and stirred at a rate of 240 rpm for 8 minutes to obtain a mixture A;

[0046] Step 2, mixing the unsymmetrical dimethylhydrazine, diisopropyl ether, cyclohexanol and butylene oxide in the parts by weight, and stirring at a rate of 200 rpm for 11 minutes to obtain a mixture B;

[0047] Step 3, the n-hexanoic acid (N-dodecylglucose) ammonium, tert-butanol, methylcyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com