Frozen fermented dough containing citrus fiber as well as preparation method and application of frozen fermented dough

A technology of citrus fiber and fermented dough, applied in dough preparation, application, dough processing, etc., can solve the problems of poor bread appearance, taste and texture, hard texture, poor rheology, etc., to promote diversification Product development, meeting diversified consumer needs, improving survival rate and frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

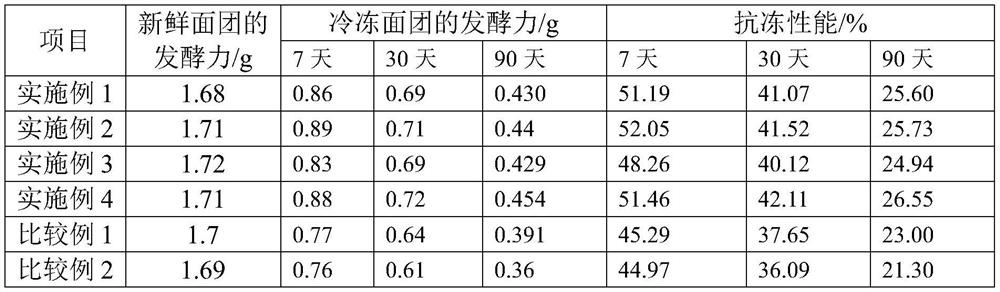

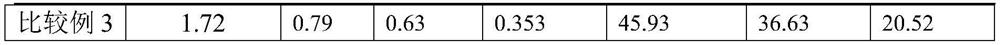

Embodiment 1

[0029] A. Prepare 0.25 parts of citrus fiber powder, 46 parts of high-gluten wheat flour, 8.4 parts of Korean castor sugar, 2.8 parts of dry yeast, 2.8 parts of whole milk powder, 4.6 parts of yellow cream, 4.6 parts of egg liquid, 0.45 parts of edible refined salt, 0.9 Composite frozen dough improver, 29.2 parts of ice water, standby; Composite frozen dough improver, in parts by mass, includes 45 parts of wheat flour, 40 parts of diacetyl tartaric acid mono-diglycerides, 20 parts of calcium carbonate, vitamin C4 0.1 part of α-amylase, 0.2 part of lipase, 0.1 part of xylanase, and 0.2 part of glucose oxidase.

[0030] B. At a room temperature of 20°C and a humidity of 55% RH, mix citrus fiber powder, high-gluten wheat flour, Korean castor sugar, dry yeast, whole milk powder, and compound frozen dough improver, and stir at 140 rpm for 1 min;

[0031] C. Add ice water, stir at 140 rpm for 2 minutes; then stir at 280 rpm for 2 minutes;

[0032] D. Add yellow butter and edible re...

Embodiment 2

[0040] A. Prepare 0.5 parts of citrus fiber powder, 48.8 parts of high-gluten wheat flour, 8.8 parts of Korean castor sugar, 3.2 parts of fresh yeast, 4.4 parts of whole milk powder, 3.9 parts of yellow butter, 2.4 parts of egg liquid, 0.67 parts of refined edible salt, 0.98 26.35 parts of ice water for subsequent use; Composite frozen dough improver, in parts by mass, includes 53 parts of wheat flour, 20 parts of diacetyl tartaric acid mono-diglycerides, 30 parts of calcium carbonate, vitamin C3 part, 0.2 part of α-amylase, 0.1 part of lipase, 0.2 part of xylanase, 0.1 part of glucose oxidase.

[0041] B. At a room temperature of 25°C and a humidity of 75% RH, mix citrus fiber powder, high-gluten wheat flour, Korean castor sugar, fresh yeast, whole milk powder, and compound frozen dough improver, and stir at 120 rpm for 1 min;

[0042] C. Add ice water, stir at 120 rpm for 2 minutes; then stir at 270 rpm for 2 minutes;

[0043] D. Add yellow butter and edible refined salt, s...

Embodiment 3

[0051] A. Prepare 0.2 parts of citrus fiber powder, 65 parts of high-gluten wheat flour, 5.5 parts of Korean castor sugar, 5 parts of fresh yeast, 1 part of whole milk powder, 7.3 parts of yellow butter, 2.3 parts of egg liquid, 0.9 parts of refined edible salt, 0.9 30 parts of compound frozen dough improver, 30 parts of ice water, standby; Composite frozen dough improver, in parts by mass, includes 50 parts of wheat flour, 30 parts of diacetyl tartaric acid mono-diglycerides, 25 parts of calcium carbonate, vitamin 3.5 parts of C, 0.15 parts of α-amylase, 0.15 parts of lipase, 0.15 parts of xylanase, and 0.15 parts of glucose oxidase.

[0052] B. At a room temperature of 20°C and a humidity of 55% RH, mix citrus fiber powder, high-gluten wheat flour, Korean castor sugar, fresh yeast, whole milk powder, and compound frozen dough improver, and stir at 130 rpm for 1 min;

[0053] C. Add ice water, stir at 130 rpm for 2 min; then stir at 280 rpm for 2 min;

[0054] D. Add yellow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com