Camellia sinensis var.assamica and preparation process thereof

A preparation process, Pu-erh tea technology, applied in the field of tea, can solve problems such as long fermentation time, loss of tea leaves, and unguaranteed quality of prepared products, and achieve good fermentation effect, improve quality, and maintain moisture balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

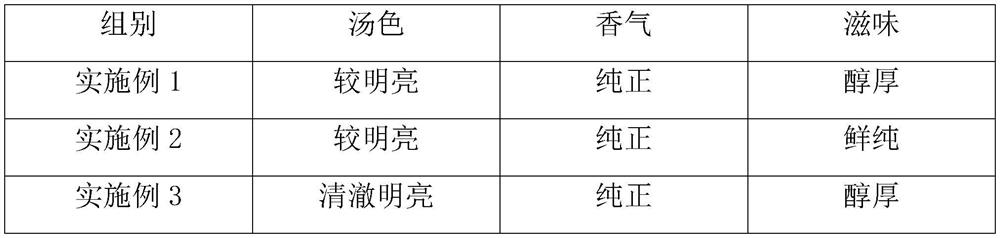

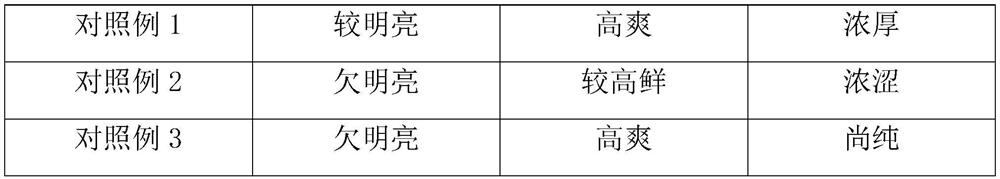

Examples

Embodiment 1

[0034] Present embodiment is a kind of preparation technology of Pu'er tea, comprises the following steps:

[0035] (a) According to the quantitative ratio of 5:6:3:3:2, Aspergillus niger, Aspergillus foetidus, Aspergillus japonicus, Penicillium and saccharomyces were prepared into a bacterial suspension, wherein the concentration of the bacterial suspension was 1× 10 8 cfu / ml;

[0036] (b) Put the compound amino acid, glucose, mannitol, and inulin in the bacterial suspension according to the mass ratio of 1:3:0.5:1:100 to obtain a mixed solution, wherein the compound amino acid consists of an equal amount of serine, glycine, alanine amino acid, isoleucine, leucine and histidine composition;

[0037] (c) Mix the mixed solution with Yunnan big-leaf sun-dried green tea according to the mass ratio of 1:8, and then carry out heap fermentation for 18 days, and control the water content of Yunnan big-leaf sun-dried green tea to 35-35 40%, the fermentation temperature is 45-60°C, ...

Embodiment 2

[0039] Present embodiment is a kind of preparation technology of Pu'er tea, comprises the following steps:

[0040] (a) According to the quantitative ratio of 5:6:3:3:2, Aspergillus niger, Aspergillus foetidus, Aspergillus japonicus, Penicillium and saccharomyces were prepared into a bacterial suspension, wherein the concentration of the bacterial suspension was 5× 10 8 cfu / ml;

[0041] (b) According to the mass ratio of 2:2:1:0.5:150, the compound amino acid, glucose, mannitol, and inulin are placed in the bacterial suspension to obtain a mixed solution, wherein the compound amino acid consists of an equal amount of serine, glycine, alanine amino acid, isoleucine, leucine and histidine composition;

[0042] (c) Mix the mixed solution with Yunnan big-leaf sun-dried green tea according to the mass ratio of 1:10, then carry out heap fermentation for 20 days, and control the water content of Yunnan big-leaf sun-dried green tea to 35-35 40%, the fermentation temperature is 45-6...

Embodiment 3

[0044] Present embodiment is a kind of preparation technology of Pu'er tea, comprises the following steps:

[0045] (a) According to the quantitative ratio of 5:6:3:3:2, Aspergillus niger, Aspergillus foetidus, Aspergillus japonicus, Penicillium and yeast were prepared into a bacterial suspension, wherein the concentration of the bacterial suspension was 4× 10 8 cfu / ml;

[0046] (b) According to the mass ratio of 1.5: 2: 0.8: 0.8: 120, the compound amino acid, glucose, mannitol, and inulin are placed in the bacterial suspension to obtain a mixed solution, wherein the compound amino acid consists of an equal amount of serine, glycine, alanine amino acid, isoleucine, leucine and histidine composition;

[0047] (c) Mix the mixed solution with Yunnan big-leaf sun-dried green tea according to the mass ratio of 1:9, and then carry out heap fermentation for 19 days, and control the moisture content of Yunnan big-leaf sun-dried green tea to 35-35 40%, the fermentation temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com