Basalt fiber reinforced regenerated micro-powder geopolymer and preparation method thereof

A basalt fiber and geopolymer technology, applied in the field of materials science, can solve the problems of rising material prices and increasing the cost of preparing geopolymers, and achieve the effects of reducing prices, facilitating popularization and application, and achieving high toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention proposes a method for preparing a basalt fiber-reinforced regenerated micropowder geopolymer, which includes:

[0032] 1) taking each reaction material component according to parts by weight;

[0033] 2) Put the regenerated micropowder, metakaolin and high-efficiency activator into a sealed bag and mix evenly, set aside;

[0034] 3) Mix the basalt fiber and fiber dispersant evenly, set aside;

[0035] 4) mix the alkali activator and deionized water in the reaction vessel evenly, and set aside;

[0036] 5) Add the raw materials obtained in step 2) and step 3) into the stirring pot, start the blender and add all the alkali activators into the stirring pot within 1 minute, stir for 3-5 minutes, and obtain the basalt fiber reinforced regenerated micro-powder geopolymer .

[0037] The method for preparing a basalt fiber-reinforced geopolymer provided by the embodiment of the present invention makes full use of large and cheap construction solid waste...

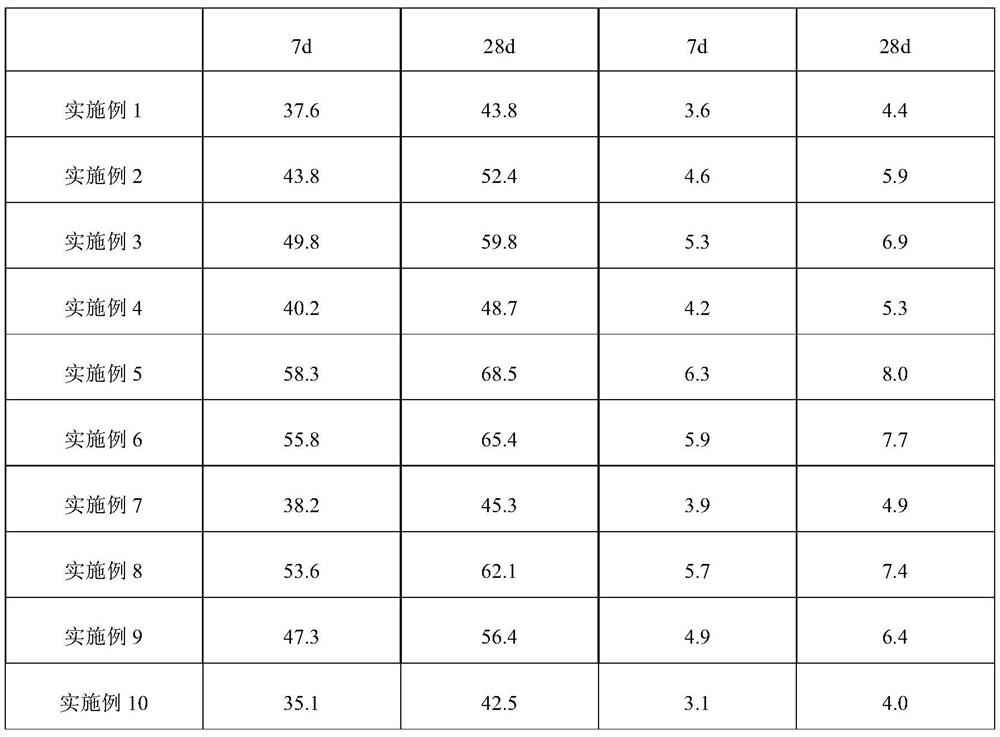

Embodiment 1

[0040] This embodiment provides a basalt fiber reinforced regenerated micropowder geopolymer, the preparation steps of which are as follows:

[0041] S101, material preparation: prepare 300 parts of recycled micropowder, 700 parts of metakaolin, 750 parts of water glass, 100 parts of sodium hydroxide, 7 parts of activator, 150 parts of deionized water, 5 parts of basalt fiber, and 3 parts of fiber dispersant. Among them, the specific surface area of metakaolin is 600m 2 / kg, basalt fiber length 3mm.

[0042] S102. Prepare powder: mix and grind 300g of regenerated micropowder and 7g of activator to obtain a specific surface area of 900m 2 / kg, the regenerated micropowder with a particle size of 20 μm, and then mix it with 700g metakaolin evenly to obtain a powder.

[0043] S103. Prepare fiber: mix basalt fiber and fiber dispersant evenly.

[0044] S104. Preparation of an alkali activator: uniformly mix 750 g of water glass, 100 g of sodium hydroxide and 150 g of deionize...

Embodiment 2

[0047]This embodiment provides a basalt fiber reinforced regenerated micropowder geopolymer, the preparation steps of which are as follows:

[0048] S201. Preparation of materials: Prepare 300 parts of recycled micropowder, 700 parts of metakaolin, 750 parts of water glass, 100 parts of sodium hydroxide, 7 parts of activator, 150 parts of deionized water, 10 parts of basalt fiber, and 3 parts of fiber dispersant. Among them, the specific surface area of metakaolin is 600m 2 / kg, basalt fiber length 3mm.

[0049] S202, powder preparation: 300g of regenerated micropowder and 7g of activator are mixed and ground to obtain a specific surface area of 900m 2 / kg, the regenerated micropowder with a particle size of 20 μm, and then mix it with 700g metakaolin evenly to obtain a powder.

[0050] S203. Prepare fiber: mix the basalt fiber and fiber dispersant evenly.

[0051] S204, preparing an alkali activator: uniformly mix 750g of water glass, 100g of sodium hydroxide and 150g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com