Preparation method of graphene modified polyurethane composite material

A technology of graphene modification and composite materials, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as low strength, poor water resistance, and poor erosion resistance, and achieve good erosion resistance and water resistance Enhanced water resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

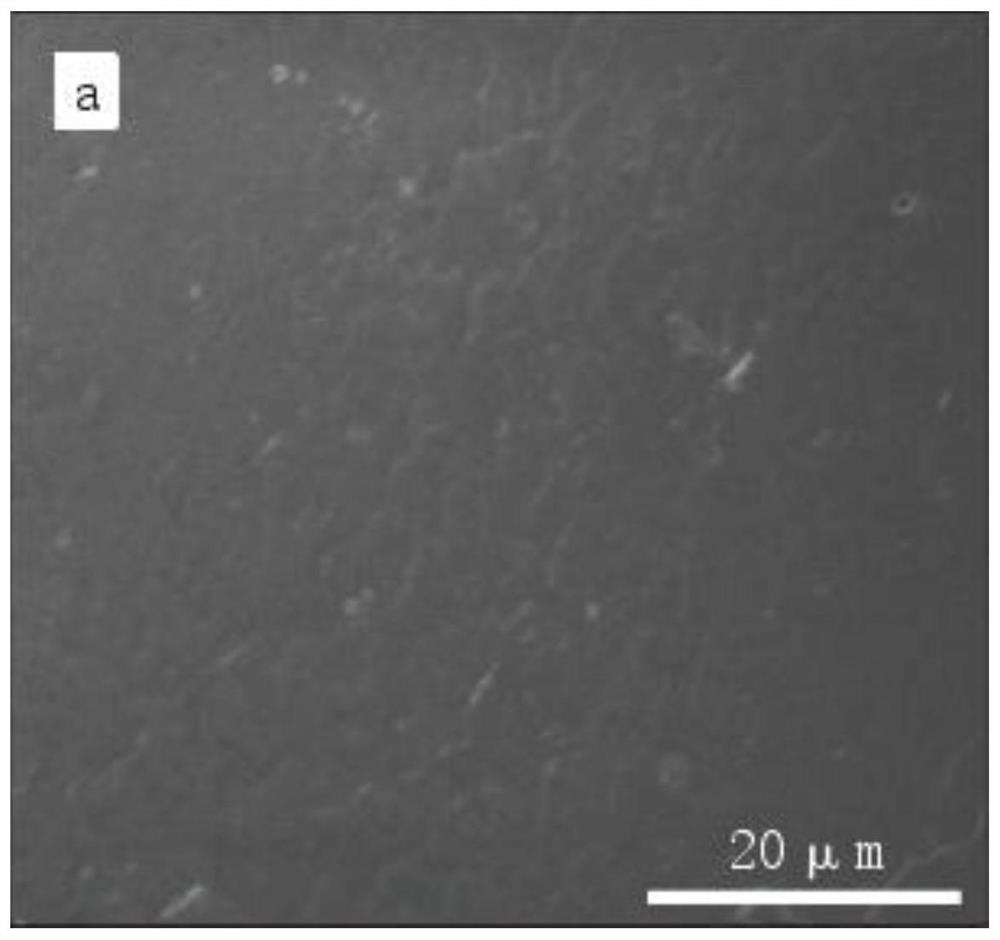

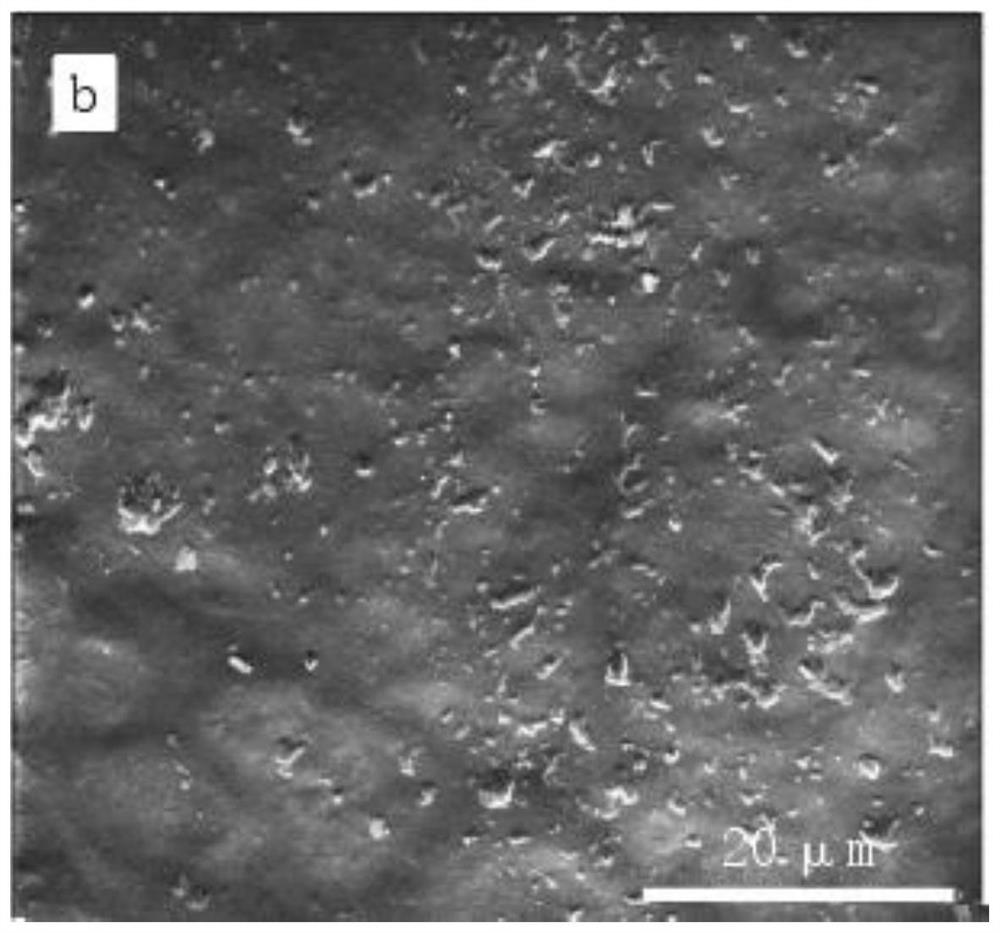

Image

Examples

Embodiment 1

[0033] A kind of preparation method of graphene modified polyurethane composite material, comprises the steps:

[0034] One, the preparation of graphene oxide:

[0035] (1) Add 200ml of 98% concentrated sulfuric acid and 5g of sodium nitrate into a dry beaker, and cool it to 5°C with ice water, then add 5g of graphite powder and 30g of potassium permanganate into the beaker and stir for 2 hours (note that adding Slowly add potassium permanganate and control the temperature of the reaction system not to exceed 15°C), after the stirring is completed, the temperature is raised to 35°C and reacted for 2 hours, after the reaction is completed, add 1000ml deionized water and stir for 30 minutes (when adding deionized water Pay attention to control the temperature between 90-98°C);

[0036] (2) then add 20ml hydrogen peroxide solution (wherein the massfraction of hydrogen peroxide is 30%) in the reaction system of step (1), and filter while hot, then wash the filter product with the...

Embodiment 2

[0044] A kind of preparation method of graphene modified polyurethane composite material, comprises the steps:

[0045] One, the preparation of graphene oxide:

[0046] (1) Add 200ml of 98% concentrated sulfuric acid and 8g of sodium nitrate into a dry beaker, and cool to 10°C with ice water, then add 8g of graphite powder and 64g of potassium permanganate into the beaker and stir for 1 hour (note that adding Slowly add potassium permanganate and control the temperature of the reaction system not to exceed 15°C), after the stirring is completed, the temperature is raised to 30°C and reacted for 3 hours, after the reaction is completed, add 1500ml deionized water and stir for 30 minutes (when adding deionized water Pay attention to control the temperature between 90-98°C);

[0047] (2) then add 23ml hydrogen peroxide solution (wherein the massfraction of hydrogen peroxide is 30%) in the reaction system of step (1), and filter while hot, then wash with the hydrochloric acid of co...

Embodiment 3

[0055] A kind of preparation method of graphene modified polyurethane composite material, comprises the steps:

[0056] One, the preparation of graphene oxide:

[0057] (1) Add 200ml of 98% concentrated sulfuric acid and 10g of sodium nitrate into a dry beaker, and cool to 7°C with ice water, then add 10g of graphite powder and 50g of potassium permanganate into the beaker and stir for 3 hours (note that adding Slowly add potassium permanganate and control the temperature of the reaction system not to exceed 15°C), after the stirring is completed, the temperature is raised to 40°C and reacted for 1 hour, after the reaction is completed, add 2000ml deionized water and stir for 30 minutes (when adding deionized water Pay attention to control the temperature between 90-98°C);

[0058] (2) then add 25ml hydrogen peroxide solution (wherein the massfraction of hydrogen peroxide is 30%) in the reaction system of step (1), and filter while hot, then wash with the hydrochloric acid of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com