Pollution-resistant modified porous membrane and preparation method thereof

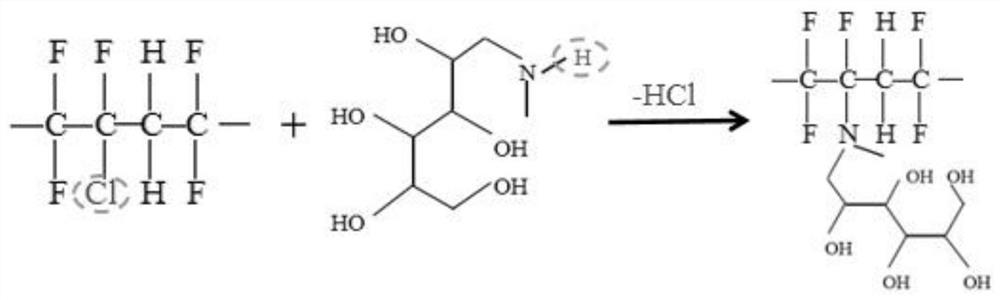

A porous membrane and pollution-resistant technology, which is applied in the field of membrane separation, can solve the problems of pollution resistance and difficult chemical graft modification, and achieve the effects of avoiding the problem of clogging membrane pores, mild reaction conditions and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

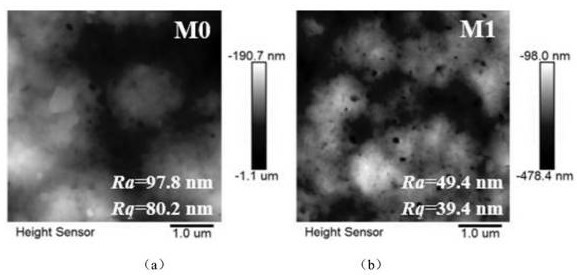

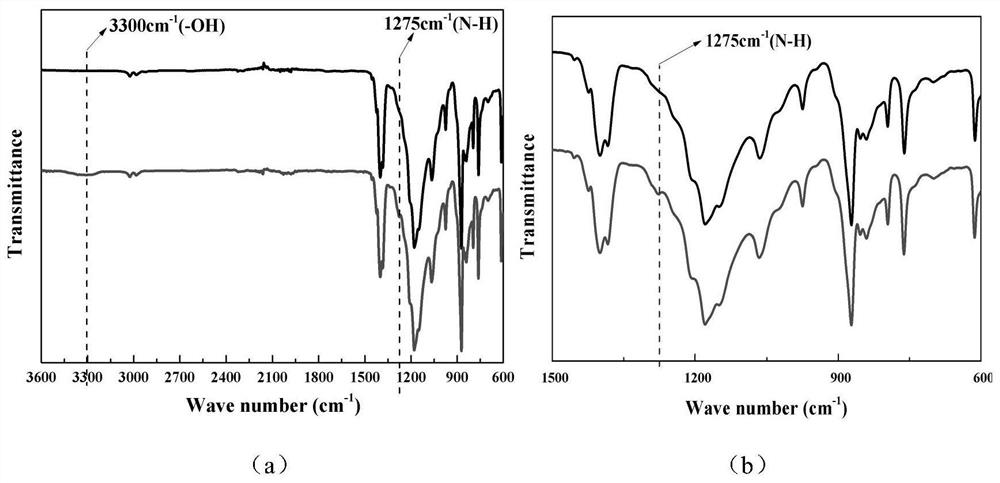

[0044] After heating and mixing 1 kg of vinylidene fluoride-chlorotrifluoroethylene copolymer, 1.8 kg of dioctyl phthalate, and 200 g of glucosamine at 210 degrees for 1 hour, extrude to prepare hollow Fibrous porous membrane. The inner diameter of the porous membrane is 0.8mm. Wall thickness 0.2mm, membrane pure water flux 810L / m 2 .h@bar, the water contact angle on the membrane surface is 61 degrees.

Embodiment 2

[0048] The vinylidene fluoride-chlorotrifluoroethylene copolymer porous membrane prepared in Comparative Example 1 was immersed in an aqueous meglumine solution with a concentration of 2mol / L and a temperature of 80 degrees for 8 hours, and was taken out for washing. Membrane pure water flux 730L / m 2 .h@bar, the membrane surface water contact angle is 58 degrees.

Embodiment 3

[0050] 1 kg of polyvinyl chloride, 2.2 kg of dimethylacetamide, 800 g of polyethylene glycol 6000, and 200 g of glucosamine were mixed and dissolved at 70 degrees for 10 hours, and a hollow Fibrous porous membrane. The inner diameter of the porous membrane is 0.8mm. Wall thickness 0.2mm, membrane pure water flux 640L / m 2 .h@bar, the membrane surface water contact angle is 49 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com