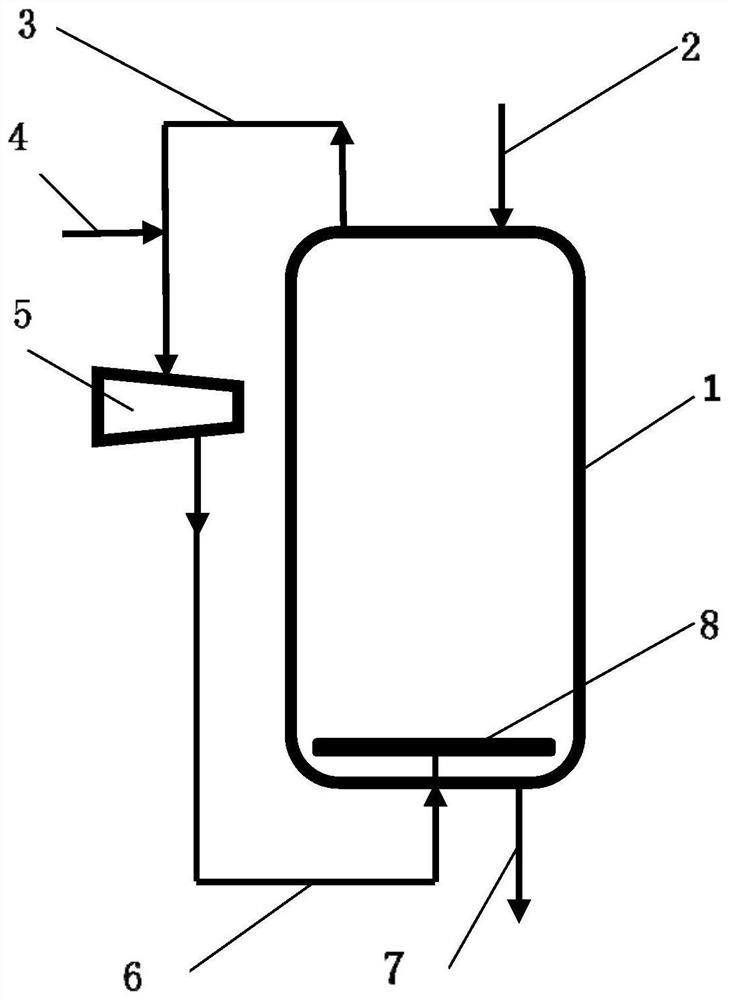

Device and process for preparing 1,1,1,3-tetrachloropropane

A tetrachloropropane and process technology, applied in the field of organic halide preparation, can solve problems such as reducing the amount of gum oil-like substances generated, and achieve the effects of avoiding collisions, avoiding safety risks, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

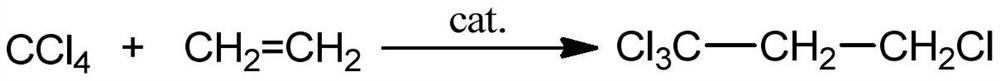

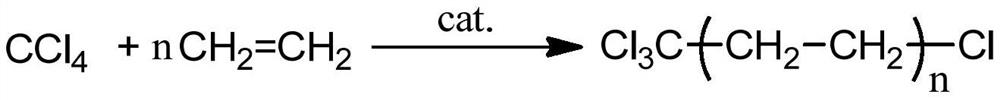

Method used

Image

Examples

Embodiment 1

[0027] A 5000L stainless steel reactor with an aspect ratio of 3, exhaust air, add catalyst ferric chloride 5kg, reduced iron powder 32kg, cocatalyst tributyl phosphite 25kg, carbon tetrachloride 3750kg, feed ethylene through the ethylene feed port , so that the ethylene pressure in the reactor reaches 0.20MPa; start the oil-free ethylene compressor, the pressure difference between the exhaust port and the inlet port is less than or equal to 1.2MPa, and the displacement of the ethylene compressor is 17.5Nm 3 / min, ethylene is drawn from the upper part of the reactor, pressurized by the ethylene compressor, and then pressed into the reactor from the lower part of the reactor, and the ethylene pressed into the reactor is distributed into the reaction system through a gas distributor, which is a multi-layer sintered metal Stencil, average pore diameter 0.45μm, porosity 38%, gas distributor area 65% of the cross-sectional area of the reactor; heat up to 95°C for reaction, supplem...

Embodiment 2

[0029] Control the ethylene pressure in the reactor to be 0.46~0.50MPa, other is the same as embodiment 1, take a sample and carry out gas chromatography analysis, 1,1,1,3-tetrachloropropane 85.4%, carbon tetrachloride 13.9%, secondary addition The by-product is 0.7%, the equivalent carbon tetrachloride conversion rate is 84.0%, and the selectivity of 1,1,1,3-tetrachloropropane is 99.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com