Method for synergistically removing activated sludge moisture from non-ferrous metal tailings

A technology of activated sludge and non-ferrous metals, which is applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of limited amount of blended combustion and high water content of sludge, and achieve the goal of improving blending The effect of burning capacity, high degree of solidification, and not easy to contaminate production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Source and composition of raw materials

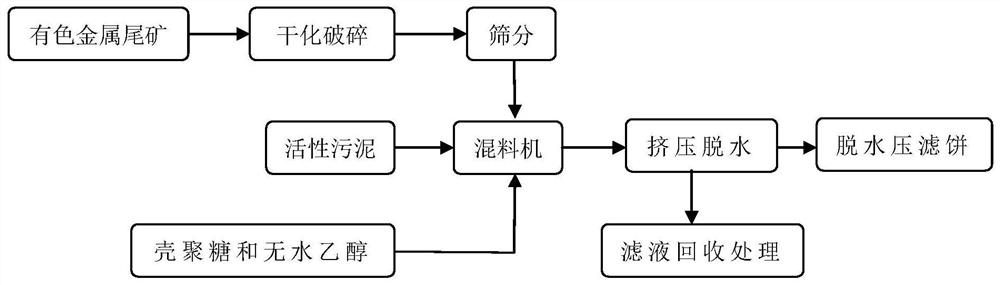

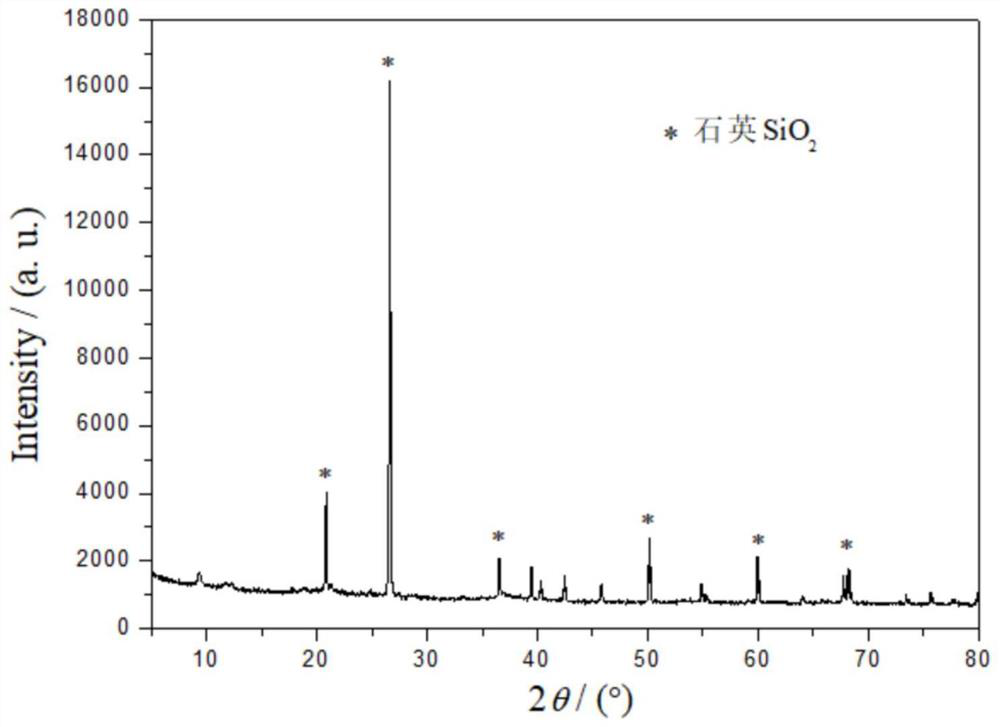

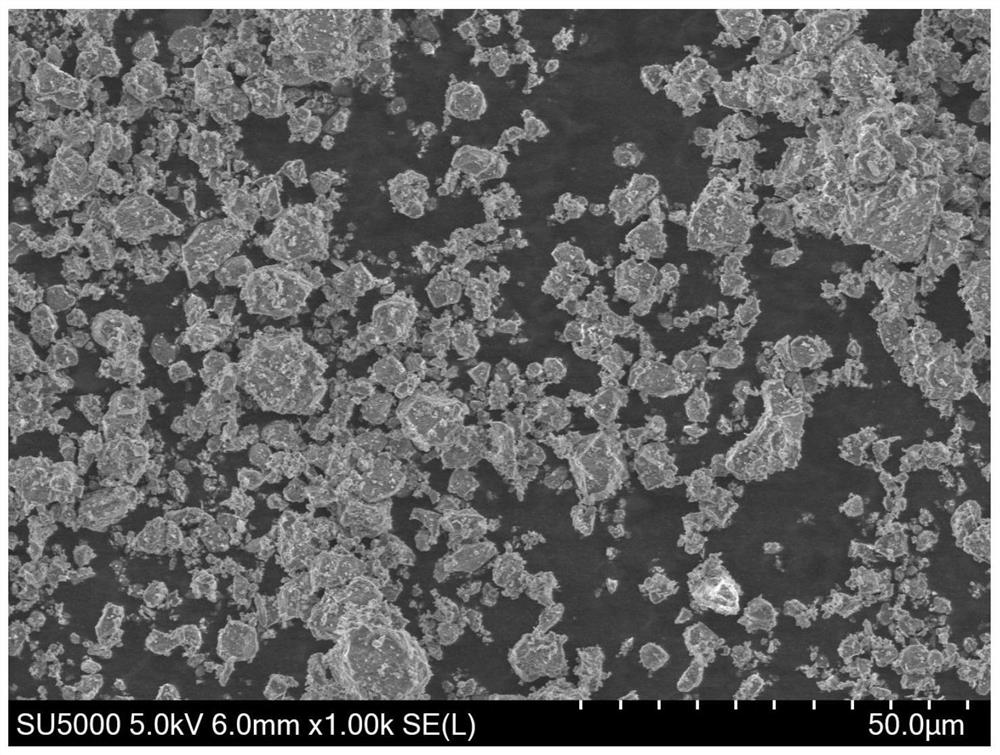

[0019] The tailings raw material used is non-ferrous metal tin ore tailings from Dachang, Nandan, Guangxi, and its XRD crystal phase structure and SEM morphology are shown in the attached figure 2 and image 3 As shown, its main components are shown in Table 1; the activated sludge raw material used is dewatered activated sludge from a municipal sewage treatment plant in Guilin, Guangxi, and its appearance is shown in the attached Figure 4 As shown, the main inorganic components in the sludge moisture content and ash are shown in Table 2; the comparison table of the main components of typical cement raw materials is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com