Municipal sludge clean incineration method and system

A municipal sludge and cleaning technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of dioxin, cement composition change, soil secondary pollution, etc., achieve low equipment investment and operation cost, prevent The formation of dioxin and the effect of increasing the mixing amount of fire prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

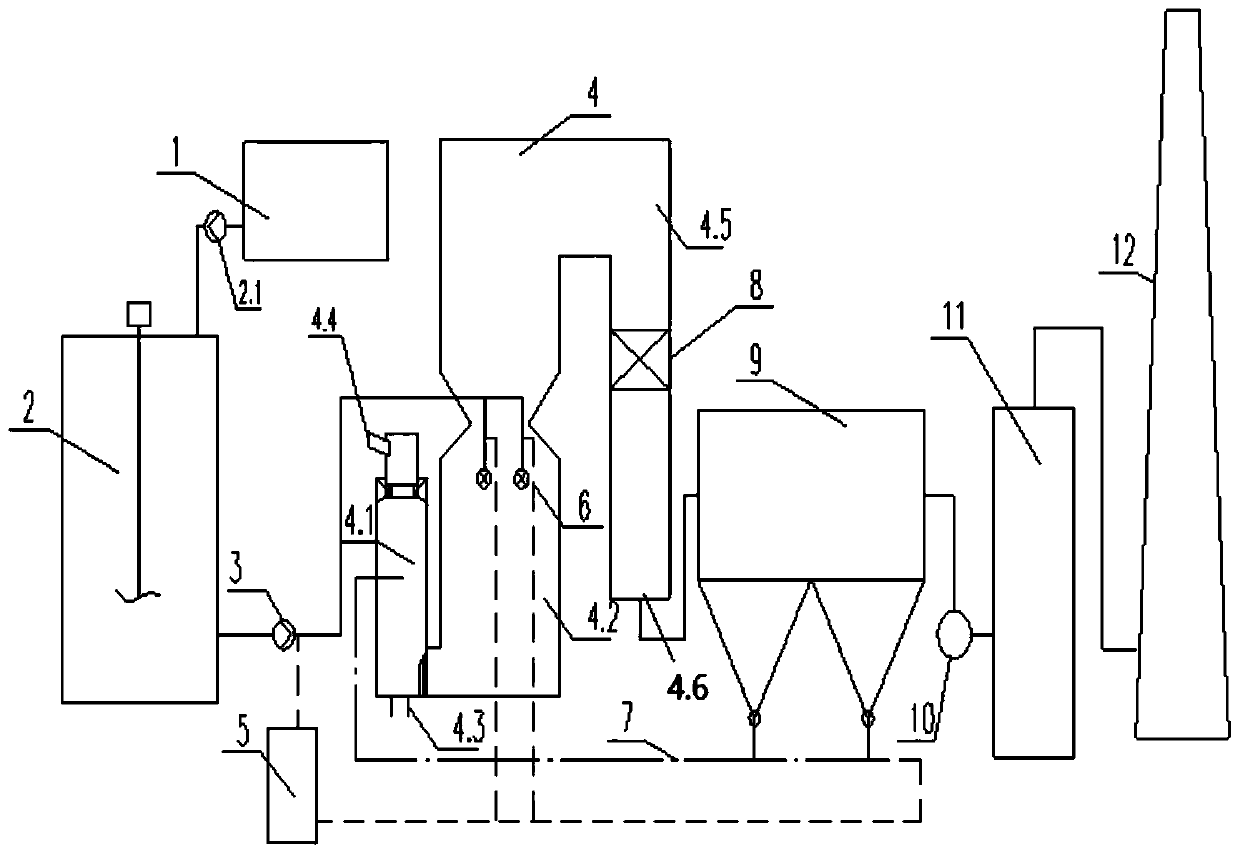

[0023] The system of the present invention will be further explained below in conjunction with the accompanying drawings:

[0024] see figure 1 , the urban sludge clean incineration system of the present invention comprises a sludge pulping system 1, a slurry delivery pump 2.1, a slurry storage tank 2, a furnace front delivery pump 3 and a sludge accompanying furnace 4 connected in sequence, and the sludge accompanying combustion The furnace 4 has a slag outlet 4.3 at the bottom and a flue gas outlet 4.6 at the top, and the flue gas outlet 4.6 is connected to the bag filter 9, the induced draft fan 10, the desulfurization tower 11 and the chimney 12 in sequence.

[0025] The sludge accompanying combustion furnace 4 includes a burnout chamber 4.2, a slagging chamber 4.1 communicated with the bottom of the burnout chamber 4.2, and a waste heat recovery chamber 4.5 communicated with the top of the burnout chamber 4.2; the upper section of the burnout chamber 4.2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com