Polyolefin composition, preparation method and application thereof

A technology for polyolefin and composition, applied in the field of polyolefin composition and its preparation, can solve the problems of high cost and difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

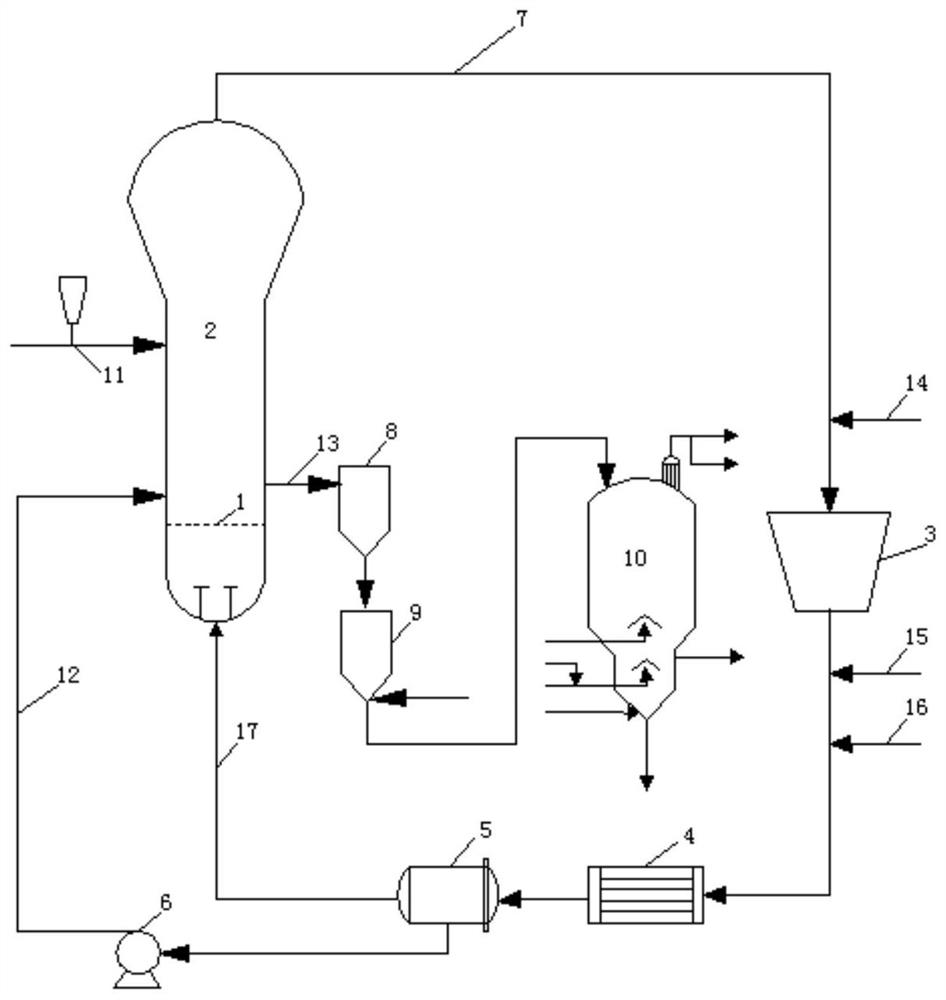

[0063] in such as figure 1 Shown interior has in the fluidized-bed reactor 2 of nitrogen fluidization, at first by pipeline 11 with the flow rate of 0.1kg / h, input a small amount of Ziegler-Natta catalyst continuously (solid component is loaded with TiCl 3 magnesium chloride, cocatalyst is triethylaluminum, Al:Ti=60), and input ethylene through pipeline 14, pipeline 15 input 1-butene and 1-hexene and pipeline 16 input a small amount of isopentane condensing agent . Then gradually increase the flow rate of the Ziegler-Natta catalyst to 5 kg / h, gradually increase the flow rate of isopentane, and keep the fluidization gas velocity constant. As the reaction progresses, ethylene is continuously input through pipeline 14, and 1-butene raw material gas is continuously input through pipeline 15, thereby forming a circulating medium in the fluidized bed reactor. Among them, the components and contents in the circulating medium are as follows: 35.2mol% ethylene, 0.8mol% 1-butene, 3.9m...

Embodiment 2

[0068] Prepare 1-butene / 1-hexene / ethylene copolymer in the same manner as in Example 1, the difference is only:

[0069] The components and contents in the circulating medium are as follows: 30.6 mol% ethylene, 0.7 mol% 1-butene, 3.6 mol% 1-hexene, 4.1 mol% hydrogen, 40.9 mol% nitrogen and 20.1 mol% isopentane.

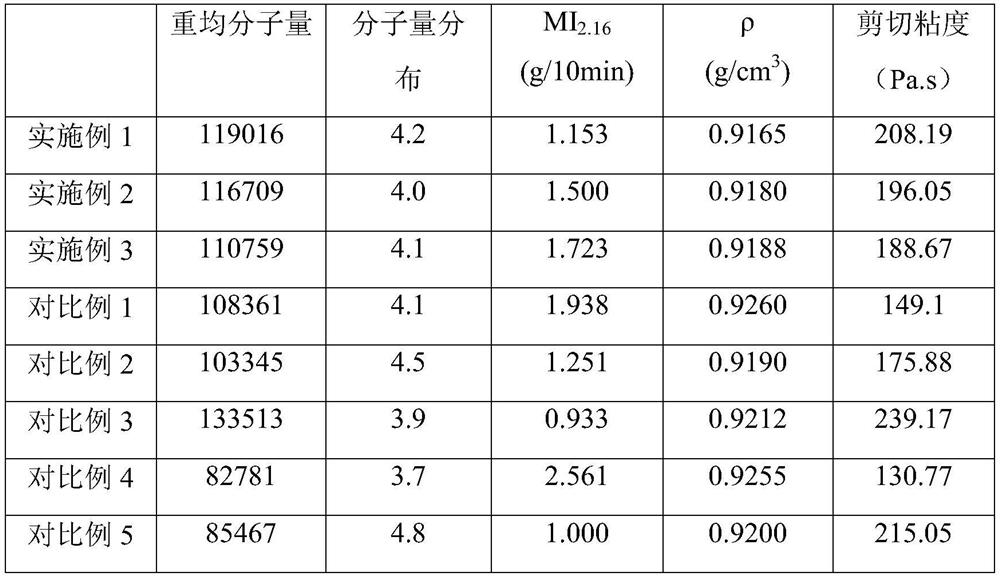

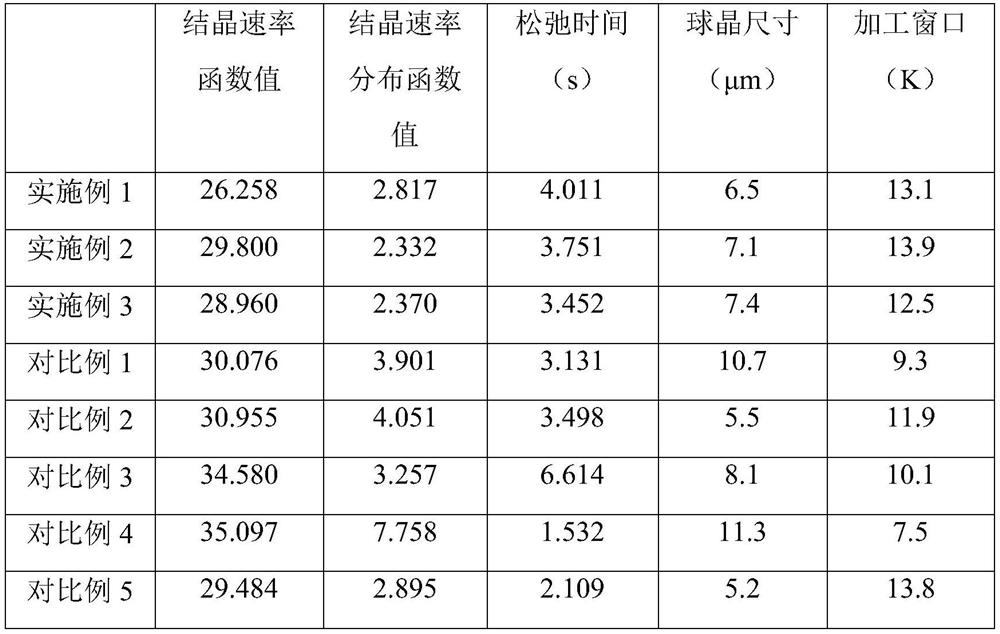

[0070] Test the properties of the prepared 1-butene / 1-hexene / ethylene copolymer, wherein the content of the structural unit derived from 1-butene is 0.43mol%, and the content of the structural unit derived from 1-hexene is 2.64mol%, the remaining results are shown in Table 1, Table 2 and Table 3.

Embodiment 3

[0072] Prepare 1-butene / 1-hexene / ethylene copolymer in the same manner as in Example 1, the difference is only:

[0073] The components and contents in the circulating medium are as follows: 28.7 mol% ethylene, 0.5 mol% 1-butene, 3.4 mol% 1-hexene, 3.8 mol% hydrogen, 46.2 mol% nitrogen and 17.4 mol% isopentane.

[0074] Test the properties of the prepared 1-butene / 1-hexene / ethylene copolymer, wherein the content of the structural unit derived from 1-butene is 0.30mol%, and the content of the structural unit derived from 1-hexene is 2.55mol%, and the remaining results are shown in Table 1, Table 2 and Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com