Active collagen lyophilized powder and preparation method thereof

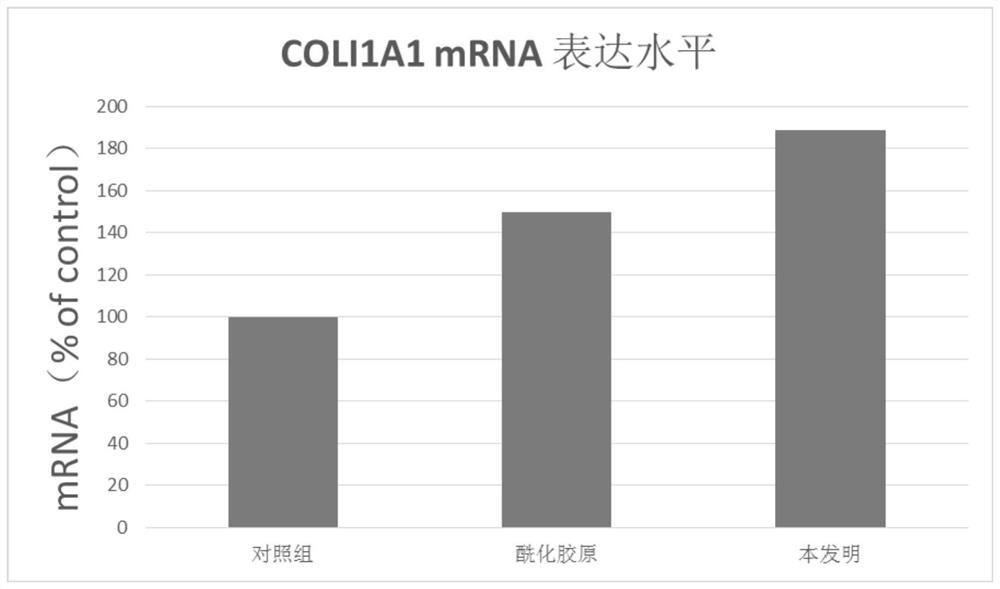

A collagen and freeze-dried powder technology, applied in the field of collagen, can solve the problems of reduced collagen stability, reduced collagen efficacy, no collagen biological activity, etc., achieves good application prospects, high dissolved concentration, and promotes skin collagen. synthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

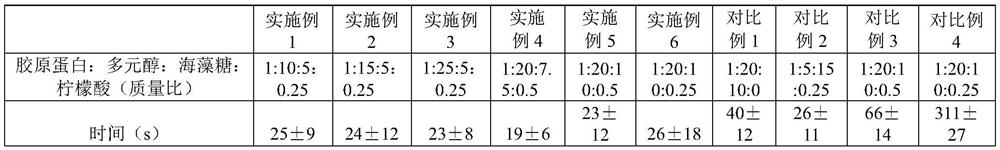

Embodiment 1

[0038] The preparation method of the active collagen freeze-dried powder of the present embodiment comprises the following steps:

[0039] 1) The collagen in the tail tendon of SD rats of SPF grade is extracted by acid-enzyme mixing method;

[0040] 2) Take 3 parts of 100mL collagen extracted in step 1), freeze-dry, and dry at 37°C for 24 hours, weigh the weight m (g) of the collagen after freeze-drying, and calculate the average value That is, the concentration of this batch of collagen;

[0041] 3) Adjust the concentration of the collagen obtained in step 2) to 4g / L with sterilized purified water;

[0042] 4) Take 100mL of 4g / L collagen, add 4g of mannitol, stir and mix until completely dissolved;

[0043] 5) Add 2 g of trehalose to the mixed solution obtained in step 4), stir and mix until completely dissolved;

[0044] 6) Add 0.1 g of citric acid to the mixed solution obtained in step 5), stir and mix until completely dissolved;

[0045] 7) The mixed solution obtained...

Embodiment 2

[0049]The preparation method of the active collagen freeze-dried powder of the present embodiment comprises the following steps:

[0050] 1) The collagen in the tail tendon of SD rats of SPF grade is extracted by acid-enzyme mixing method;

[0051] 2) Take 3 parts of 100mL collagen extracted in step 1), freeze-dry, and dry at 37°C for 24 hours, weigh the weight m (g) of the collagen after freeze-drying, and calculate the average value That is, the concentration of this batch of collagen;

[0052] 3) Adjust the concentration of the collagen obtained in step 2) to 4g / L with sterilized purified water;

[0053] 4) Take 100mL of 4g / L collagen, add 6g of mannitol, stir and mix until completely dissolved;

[0054] 5) Add 2 g of trehalose to the mixed solution obtained in step 4), stir and mix until completely dissolved;

[0055] 6) Add 0.1 g of citric acid to the mixed solution obtained in step 5), stir and mix until completely dissolved;

[0056] 7) The mixed solution obtained ...

Embodiment 3

[0058] The preparation method of the active collagen freeze-dried powder of the present embodiment comprises the following steps:

[0059] 1) The collagen in the tail tendon of SD rats of SPF grade is extracted by acid-enzyme mixing method;

[0060] 2) Take 3 parts of 100mL collagen extracted in step 1), freeze-dry, and dry at 37°C for 24 hours, weigh the weight m (g) of the collagen after freeze-drying, and calculate the average value That is, the concentration of this batch of collagen;

[0061] 3) Adjust the concentration of the collagen obtained in step 2) to 4g / L with sterilized purified water;

[0062] 4) Take 100mL of 4g / L collagen, add 10g of mannitol, stir and mix until completely dissolved;

[0063] 5) Add 2 g of trehalose to the mixed solution obtained in step 4), stir and mix until completely dissolved;

[0064] 6) Add 0.1 g of citric acid to the mixed solution obtained in step 5), stir and mix until completely dissolved;

[0065] 7) The mixed solution obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com