Amorphous cobalt borate-nickel monoselenide@foamed nickel compound as well as preparation method and application thereof

A nickel selenide, nickel foam technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as poor water splitting performance, and achieve excellent electrical conductivity, excellent hydrogen evolution and oxygen evolution. Electrocatalytic performance, effect of large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

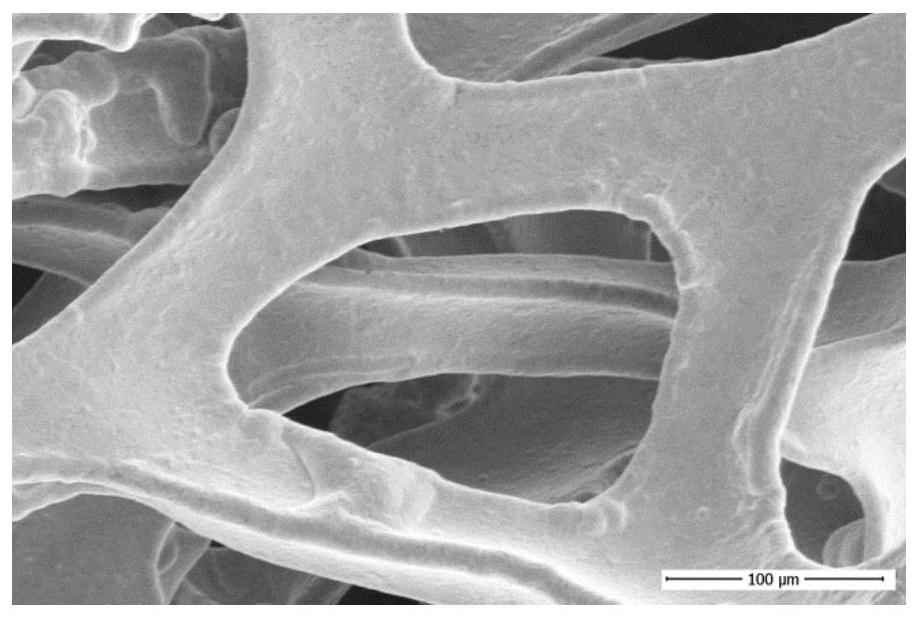

[0037] 1. First, a piece (1cm×1cm×1.5mm) of nickel foam was ultrasonically cleaned with dilute hydrochloric acid and water for 20 minutes to remove the original oxide layer of nickel foam; the surface density of the nickel foam was 280g. m -2 ;

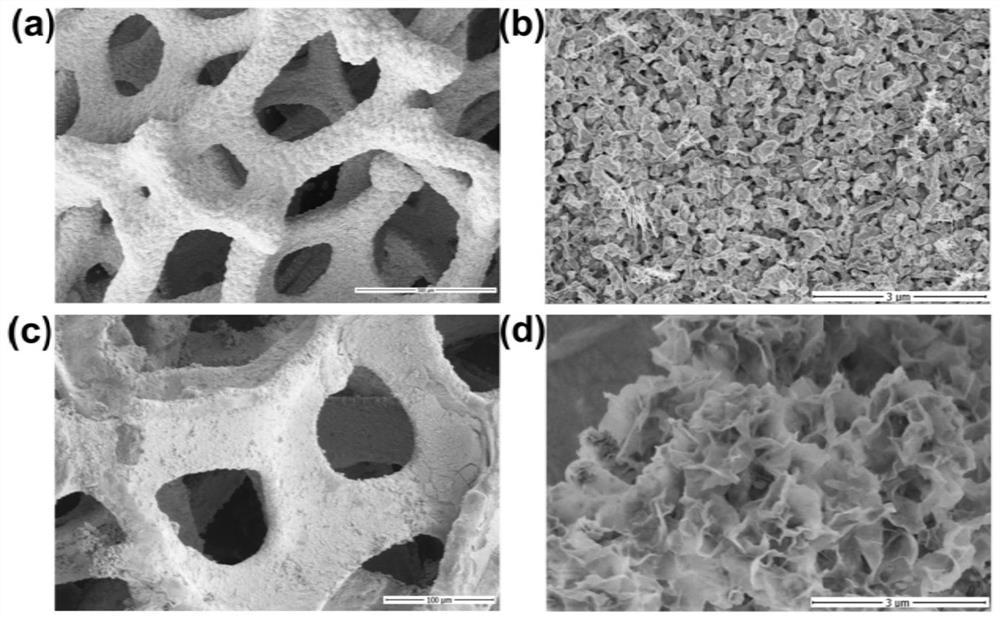

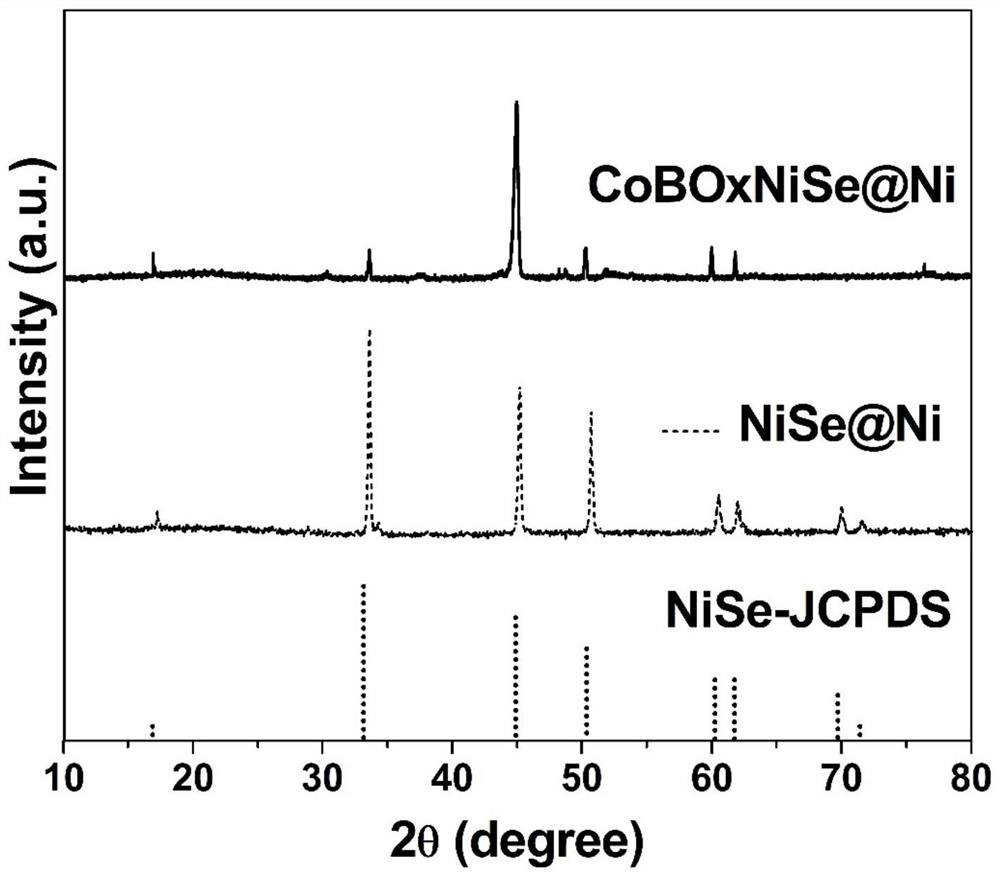

[0038] 2. Place the processed nickel foam in the middle area of the quartz tube of the tube furnace, place the selenium powder on the upstream of the quartz tube, introduce Ar continuously into the quartz tube at a rate of 100ppm, and set the temperature in the furnace to 600 ℃, set the heating rate to 10℃ / min, and the holding time to 1h, to obtain three-dimensional NiSe@Ni;

[0039] The loading mass of NiSe on the three-dimensional NiSe@Ni is 0.074mg. cm -2 ;

[0040] 3. Place the three-dimensional NiSe@Ni as a carrier on 3mMCo(NO 3 ) 2 ﹒ 6H 2 O aqueous solution, slowly add 0.5mM NaBH 4 Aqueous solution, stirred for 0.5h for reaction, after the reaction was completed, the reaction product was washed with a large amount of ...

Embodiment 2

[0047] 1. First, a piece (2cm × 2cm × 1.5mm) of nickel foam was ultrasonically cleaned with dilute hydrochloric acid and water for 40 minutes to remove the original oxide layer of nickel foam; the surface density of nickel foam was 350g m -2 ; 2. the nickel foam after the treatment is placed in the middle area of the quartz tube in the reaction furnace, and the selenium powder (loading quality is 0.1mg cm -2 ) was placed upstream of the quartz tube, and Ar was continuously introduced into the quartz tube at a rate of 80ppm, and the temperature in the furnace was set to 700°C, the heating rate was set to 8°C / min, and the holding time was 1.5h to obtain a three-dimensional NiSe@Ni;

[0048] 3. Place the three-dimensional NiSe@Ni as a carrier on 1mMCo(NO 3 ) 2 ﹒ 6H 2 O aqueous solution, and slowly add 1mM NaBH 4 Aqueous solution, stirring for 1h to react, after the reaction is completed, the obtained reaction product is CoBO x -NiSe@Ni nanosheets; the reaction product was ...

Embodiment 3

[0051] 1. First, a piece of nickel foam (1.5cm×1.5cm×1.5mm) was ultrasonically cleaned with dilute hydrochloric acid and water for 60 minutes to remove the original oxide layer of nickel foam; the surface density of nickel foam was 400g m -2 ;

[0052] 2. The nickel foam after the treatment is placed in the middle area of the quartz tube in the reaction furnace, and the selenium powder (the loading quality is 0.05mg cm -2 ) was placed upstream of the quartz tube, and Ar was continuously introduced into the reaction chamber at a rate of 120ppm, and the temperature in the furnace was set to 550°C, the heating rate was set to 9°C / min, and the holding time was 2h to obtain NiSe@Ni;

[0053] 3. Place the three-dimensional NiSe@Ni as a carrier on 2mMCo(NO 3 ) 2 ﹒ 6H 2 O aqueous solution, and slowly add 0.8mM NaBH to it 4 Aqueous solution, stirred for 2h to react, after the reaction was completed, the reaction product CoBO x NiSe@Ni nanosheets; the reaction product was washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com