Preparation method of titanium carbide hollow spheres

A technology of titanium carbide and hollow spheres is applied in the direction of titanium carbide and carbide, which can solve the problems of complex preparation process and achieve the effect of simple synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

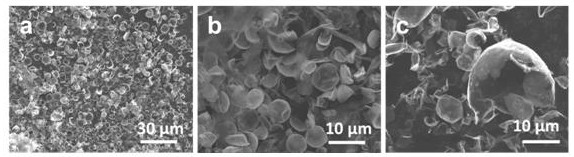

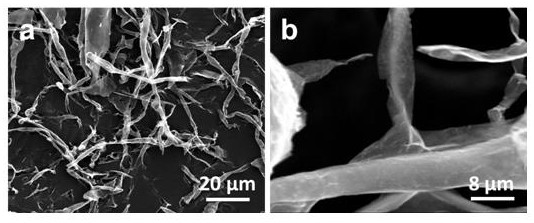

Embodiment 1

[0032] Pour 40 mL of 9 M hydrochloric acid solution into a polytetrafluoroethylene beaker and start stirring, then add 2 g of lithium fluoride and continue stirring at room temperature for 30 minutes; add 2 g of Ti 3 AlC 2 The powder was slowly added to the above solution, and then stirred and reacted at 35° C. for 24 hours. Then the corrosion products were centrifuged and the supernatant was discarded. Centrifuge and wash with deionized water for 6 times until the pH of the supernatant is 6; use absolute ethanol to sonicate for 2 hours to intercalate the precipitate after centrifugation, and then centrifuge to discard the ethanol. Then add deionized water to the sediment after the first centrifugation, after ultrasonic stripping, centrifuge again and take the suspension, add deionized water and ultrasonic stripping, then centrifuge to take the suspension, take 5 times, you can get a few layers of titanium carbide nano tablet dispersion. The few-layer titanium carbide nanos...

Embodiment 2

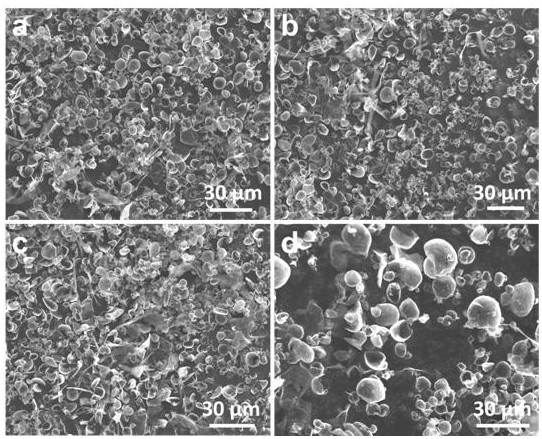

[0035] Pour 20 mL of 9 M hydrochloric acid solution into a polytetrafluoroethylene beaker and start stirring, then add 2 g of lithium fluoride and continue stirring at room temperature for 30 minutes; add 2 g of Ti 3 AlC 2 The powder was slowly added to the above solution, and then stirred and reacted at 35° C. for 24 hours. Then the corrosion products were centrifuged and the supernatant was discarded. Centrifuge and wash with deionized water for 5 times until the pH of the supernatant is 6; use absolute ethanol to sonicate for 1 hour to intercalate the precipitate after centrifugation, and then centrifuge to discard the ethanol. Then add deionized water to the sediment after the first centrifugation, after ultrasonic stripping, centrifuge again and take the suspension, add deionized water and ultrasonic stripping, then centrifuge to take the suspension, take 5 times, you can get a few layers of titanium carbide nano tablet dispersion. The few-layer titanium carbide nanosh...

Embodiment 3

[0038] Pour 60 mL of 12 M hydrochloric acid solution into a polytetrafluoroethylene beaker and start stirring, then add 1 g of lithium fluoride and continue stirring at room temperature for 60 minutes; add 0.5 g of Ti 3 AlC 2 The powder was slowly added to the above solution, and then stirred and reacted at 35° C. for 24 hours. Then the corrosion products were centrifuged and the supernatant was discarded. Centrifuge and wash with deionized water for 5 times until the pH of the supernatant is 6; use absolute ethanol to sonicate for 1.5 hours to intercalate the precipitate after centrifugation, and then centrifuge to discard the ethanol. Then add deionized water to the precipitate after the first centrifugation, after ultrasonic stripping, centrifuge again to take the suspension, add deionized water and ultrasonic stripping, then centrifuge to take the suspension, take 8 times, you can get a few layers of titanium carbide nano tablet dispersion. The few-layer titanium carbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com