Preparation method of antibacterial super absorbent resin

A technology of super absorbent resin and antibacterial agent, applied in the field of antibacterial resin, can solve the problems of complicated preparation process, poor antibacterial, poor gel strength and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

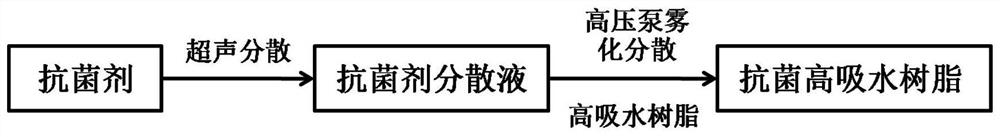

[0026] The invention provides a preparation method of an antibacterial superabsorbent resin, comprising the following steps:

[0027] Under the condition of stirring, atomize and disperse the antibacterial agent aqueous dispersion on the surface of the superabsorbent resin beads to obtain the antibacterial superabsorbent resin;

[0028] The antibacterial agent in the aqueous dispersion of the antibacterial agent is selected from one or more of chitosan, aloe freeze-dried powder, polyhexanide hydrochloride, nano-silver, nano-zinc oxide and quaternary ammonium salt;

[0029] The superabsorbent resin beads are selected from partially hydrolyzed polyacrylamide and / or sodium polyacrylate.

[0030] The present invention uses partially hydrolyzed polyacrylamide and / or sodium polyacrylate as the superabsorbent resin matrix, combines their high water absorption characteristics, and through a simple mixed adsorption process, utilizes the adsorption of the superabsorbent resin to the wat...

Embodiment 1

[0045] The preparation of embodiment 1 chitosan composite antibacterial superabsorbent resin:

[0046] Accurately measure 100g of chitosan aqueous dispersion with a concentration of 5.0%, put it into the storage tank of the high-pressure pump, set the pressure of the high-pressure pump to 0.5MPa, and spray and disperse evenly in 10 batches at a stirring speed of 50 rpm The surface of 45g of sodium polyacrylate beads was mixed evenly, and the prepared chitosan composite antibacterial superabsorbent resin was collected and dried in a 50°C oven for 24 hours to obtain an antibacterial superabsorbent resin.

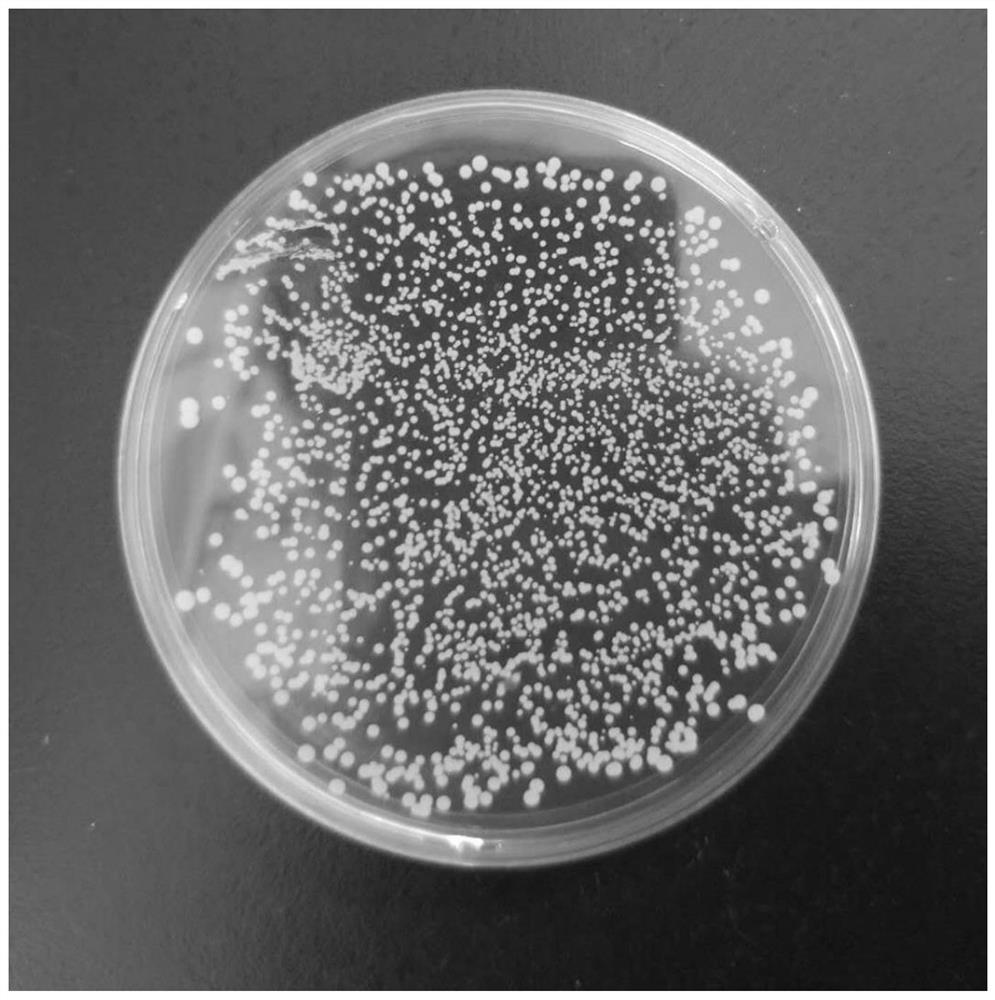

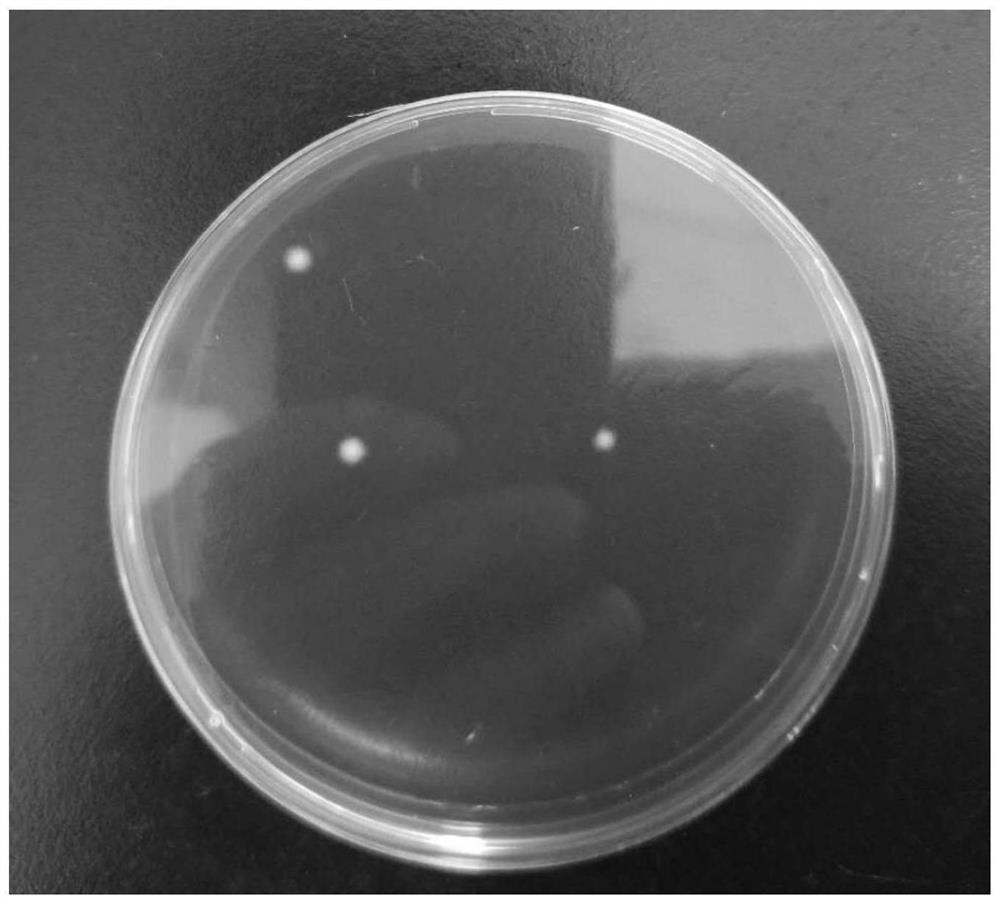

[0047] Refer to GB / T 20944.3-2008 and GB / T 22875-2018 to evaluate its antibacterial performance and absorption performance respectively. The test results are shown in Table 1. figure 2 Bacteriostatic experiment of the antibacterial superabsorbent resin prepared in Example 1 of the present invention on Escherichia coli.

Embodiment 2

[0048] Embodiment 2 Preparation of aloe freeze-dried powder composite antibacterial superabsorbent resin:

[0049] Accurately measure 100g of aloe vera freeze-dried powder aqueous dispersion with a concentration of 50.0%, put it into the storage tank of the high-pressure pump, set the pressure of the high-pressure pump to 1.0MPa, and spray and disperse evenly in 20 batches at a stirring speed of 100 rpm The surface of 50g sodium polyacrylate beads per minute was stirred and evenly mixed, and the prepared aloe freeze-dried powder composite antibacterial superabsorbent resin was collected and placed in a 50°C oven for drying treatment for 24 hours to obtain an antibacterial superabsorbent resin.

[0050] Refer to GB / T 20944.3-2008 and GB / T 22875-2018 to evaluate its antibacterial performance and absorption performance respectively. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com