Preparation method of perovskite quantum dot/Eu-MOF composite luminescent material

A technology of luminescent materials and quantum dots, applied in luminescent materials, chemical instruments and methods, sustainable buildings, etc., can solve the problems of lack of red light region of white LED and poor stability of perovskite quantum dots, and achieve excellent optical properties, Good dispersion and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

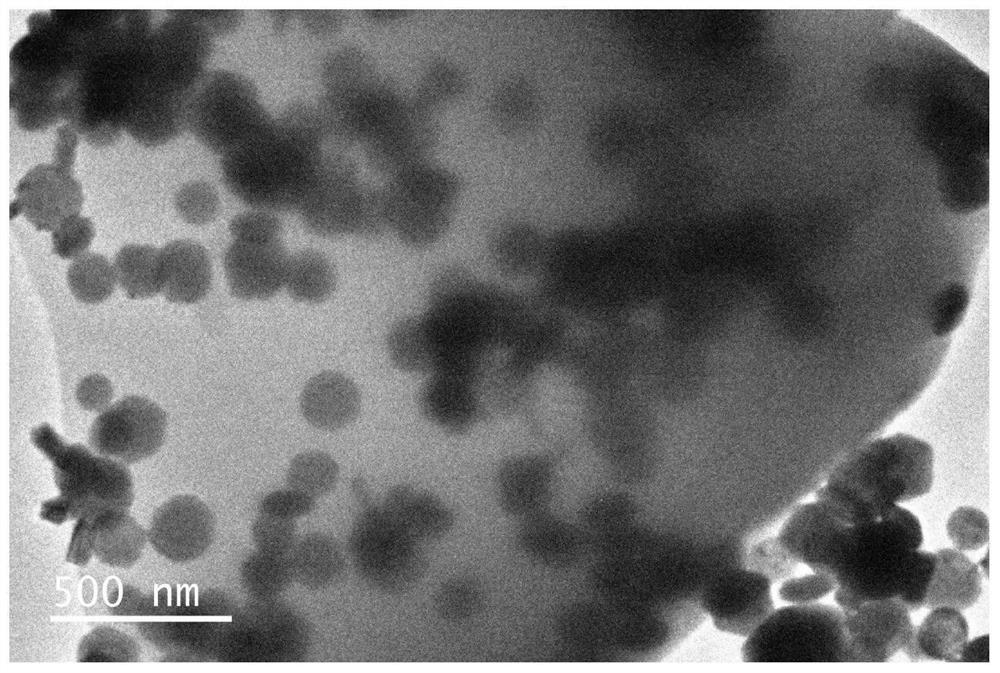

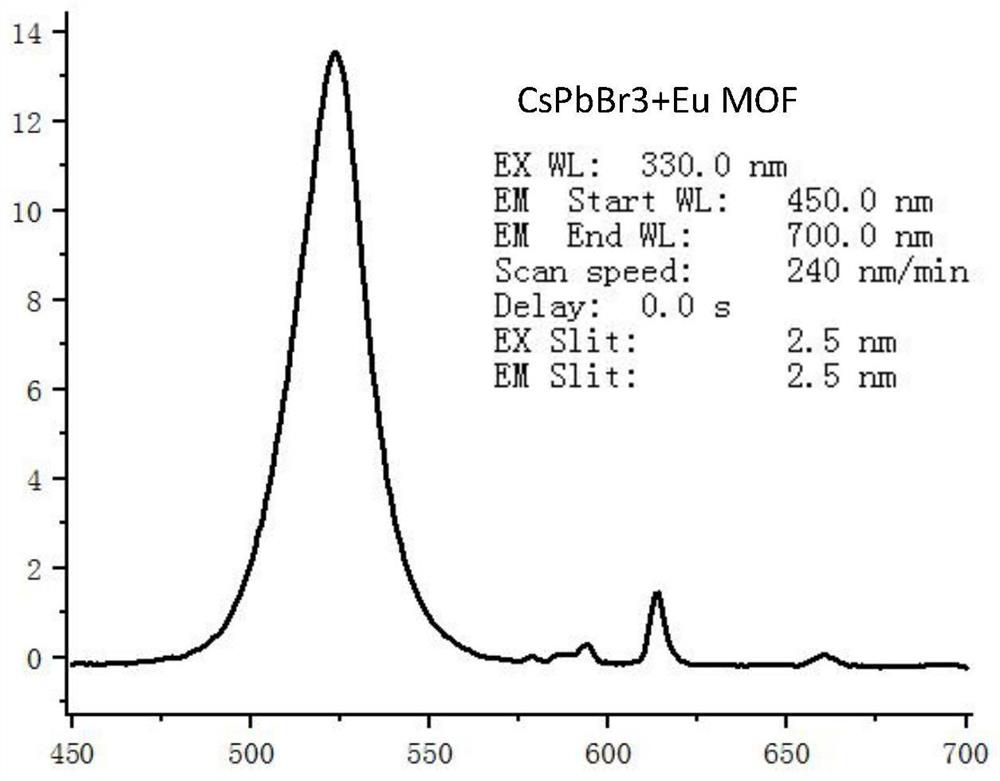

Image

Examples

preparation example Construction

[0031] The preparation method of the perovskite quantum dot / Eu-MOF composite luminescent material provided by the application comprises the following steps:

[0032] S1. Europium nitrate hexahydrate and biphenyltetracarboxylic acid are added in the aqueous solution of DMF (N,N-dimethylformamide), and the mol ratio of europium nitrate hexahydrate and biphenyltetracarboxylic acid is 1:(0.2-1 );

[0033] Put the above mixed solution into the reaction kettle and heat it to 100-150°C for 10-48h; naturally cool to room temperature, filter and purify the product, remove the residual DMF (N,N-dimethylformamide), and pass through the vacuum Eu-MOF crystals were obtained after drying;

[0034] In the above scheme, the rigid and highly symmetrical biphenyltetracarboxylic acid is used to prepare Eu-MOF crystals, which has a better energy transfer effect, and then obtains MOF materials with excellent fluorescence properties;

[0035] S2. Combine the dried Eu-MOF crystal with PbBr 2 Afte...

Embodiment 1

[0050] Weigh 1.784g (4mmol) of Eu(NO 3 ) 3 ·6H 2 O, the biphenyltetracarboxylic acid of 0.6605g (2mmol), add the N of 7.5ml under stirring, the H of N-dimethylformamide (DMF) and 2.5ml 2 O solution;

[0051] Then put the above mixed solution in a Teflon autoclave liner with a volume of 50ml, and heat it at 120°C for 48 hours; after cooling, the obtained powder is filtered out and washed with DMF, and then washed with chloroform solution , to remove residual DMF;

[0052] The obtained product was vacuum-dried at 80° C. for 2 hours to obtain Eu-MOF crystals.

[0053] The above-mentioned Eu-MOF crystal 0.4g after drying and the PbBr of 0.1468g 2 Mix and stir for a period of time in 10ml of DMF solution to obtain PbBr 2 Precursor solution of @Eu-MOF;

[0054] to PbBr again 2 Add 0.085g of CsBr solution to @Eu-MOF precursor solution, stir until clear, then add 1ml of oleic acid and 0.5ml of oleylamine;

[0055] Transfer 1ml of the prepared solution to 10ml of toluene solut...

Embodiment 2

[0058] Weigh 1.784g (4mmol) of Eu(NO 3 ) 3 ·6H 2 O, the biphenyltetracarboxylic acid of 0.6605g (2mmol), add the N of 7.5ml under stirring, the H of N-dimethylformamide (DMF) and 2.5ml 2 O solution;

[0059] Then put the above mixed solution in a Teflon autoclave liner with a volume of 50ml, and heat it at 100°C for 48 hours; after cooling, the obtained powder is filtered out and washed with DMF, and then washed with chloroform solution , to remove residual DMF;

[0060] The obtained product was vacuum-dried at 80° C. for 2 hours to obtain Eu-MOF crystals.

[0061] The above-mentioned Eu-MOF crystal 0.4g after drying and the PbBr of 0.1468g 2 Mix and stir for a period of time in 10ml of DMF solution to obtain PbBr 2 Precursor solution of @Eu-MOF;

[0062] to PbBr again 2 Add 0.085g of CsBr solution to @Eu-MOF precursor solution, stir until clear, then add 1ml of oleic acid and 0.5ml of oleylamine;

[0063] Transfer 1ml of the prepared solution to 10ml of toluene solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com