Preparation method of ultrathin graphene-like carbon material for supercapacitor

A supercapacitor and graphene carbon technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, circuits, etc., can solve the problems of difficult access to precursors, complicated and cumbersome preparation processes, and low doping amount of heteroatom nitrogen. , to achieve the effect of excellent conductivity, wide source of raw materials, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

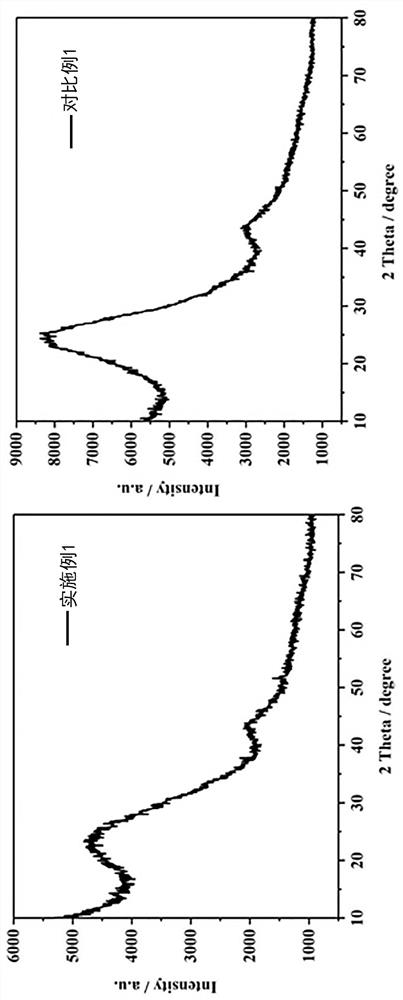

Embodiment 1

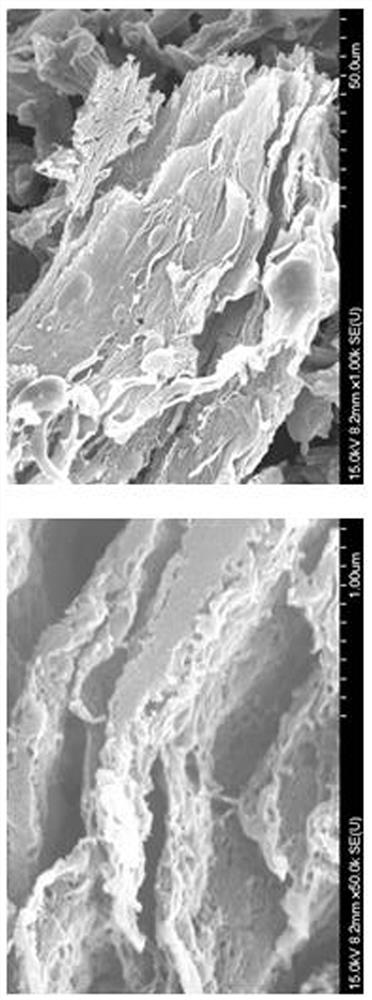

[0041] A kind of preparation method of ultra-thin graphene-like carbon material for supercapacitor, comprises the following steps:

[0042] S1: Weigh 1.0671 g of aniline solution (1 mL), 4 g of melamine, wherein the mass ratio of aniline to melamine is 1:4, measure 1.14 mL of glacial acetic acid, add the above materials into a 100 mL beaker, add 30 mL Deionized water, sonication for 30 minutes, and then continuous stirring for 4 hours to obtain a uniform mixed solution (the chemical reagents described in step S1 are all analytically pure);

[0043] S2: Weigh 1.3 g of ammonium persulfate, add 30 mL of deionized water to obtain an ammonium persulfate solution, add the ammonium persulfate solution dropwise to the mixed solution prepared in step S1, react at room temperature for 12 hours, and continue stirring during this period to obtain Compounds of melamine and polyaniline;

[0044] S3: Transfer 60 mL of the compound into a 100 mL high-pressure hydrothermal kettle, add 2 mL of...

Embodiment 2

[0050] A kind of preparation method of ultra-thin graphene-like carbon material for supercapacitor, comprises the following steps:

[0051] S1: Weigh 1.0671 g of aniline solution (1 mL), 4 g of dicyandiamide, wherein the mass ratio of aniline to dicyandiamide is 1:4, measure 1.14 mL of glacial acetic acid, and add the above materials into a 100 mL beaker , add 30 mL of deionized water, sonicate for 30 min, and then continue to stir for 4 h to obtain a uniform mixed solution (the chemical reagents described in step S1 are all analytically pure);

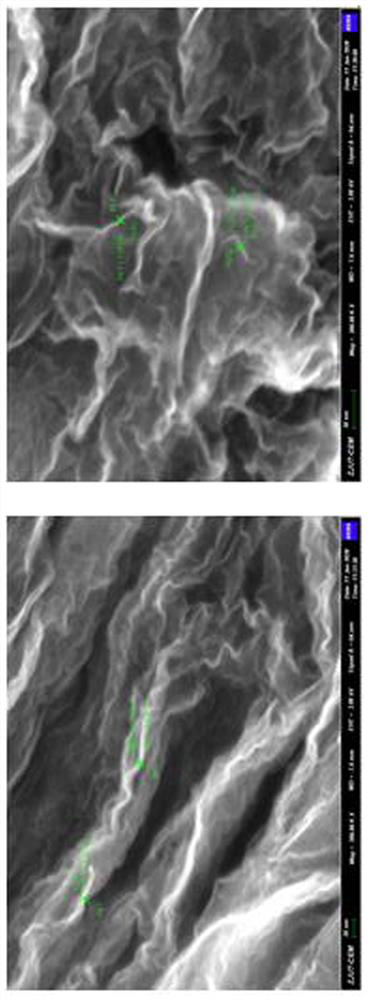

[0052] The remaining steps and processes are the same as in Example 1. The solid powder is tested by SEM, and the thickness of the graphene-like carbon material flake is 1.58nm.

Embodiment 3

[0054] S1: Weigh 1.0671 g of aniline solution (1 mL), 4 g of melamine, wherein the mass ratio of aniline to melamine is 1:4, measure 1.14 mL of concentrated sulfuric acid, add the above materials into a 100 mL beaker, add 30 mL Deionized water, sonication for 30 minutes, and then continuous stirring for 4 hours to obtain a uniform mixed solution (the chemical reagents described in step S1 are all analytically pure);

[0055] The remaining steps and processes are the same as in Example 1. The solid powder is tested by SEM, and the thickness of the graphene-like carbon material flake is 5.6nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com