Heteroatom-containing covalent organic framework electrode material and preparation method and application thereof

A covalent organic framework and electrode material technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor conductivity, reduce interface resistance, increase conductivity, and prevent aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

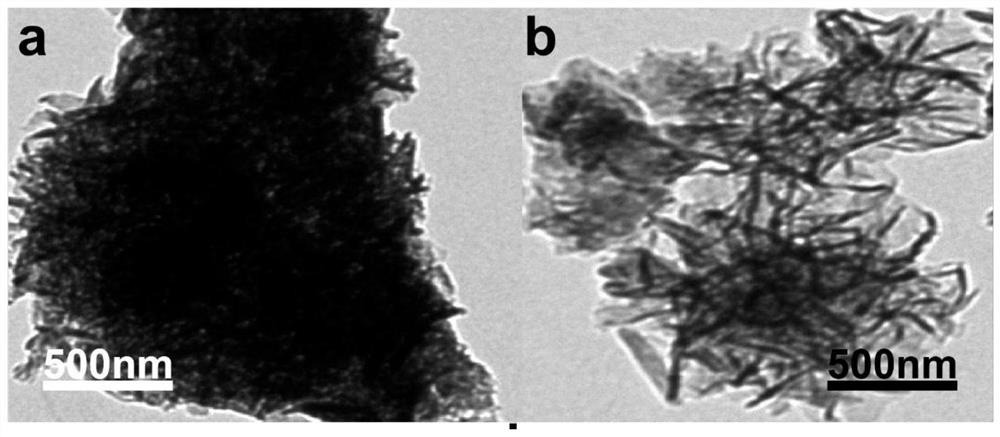

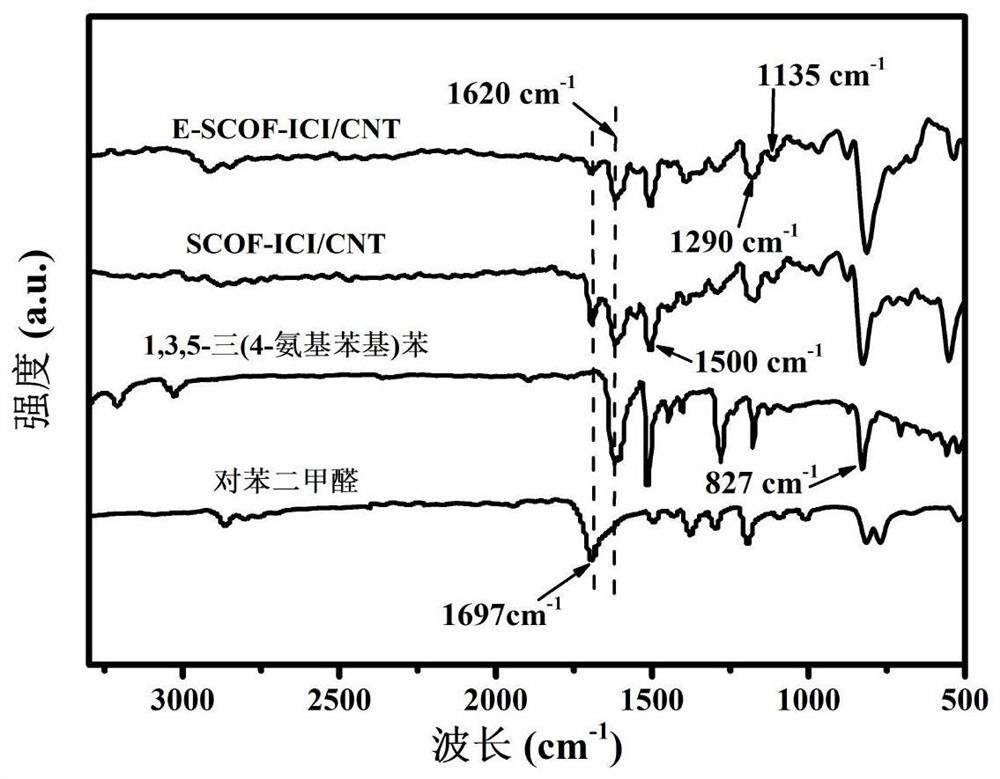

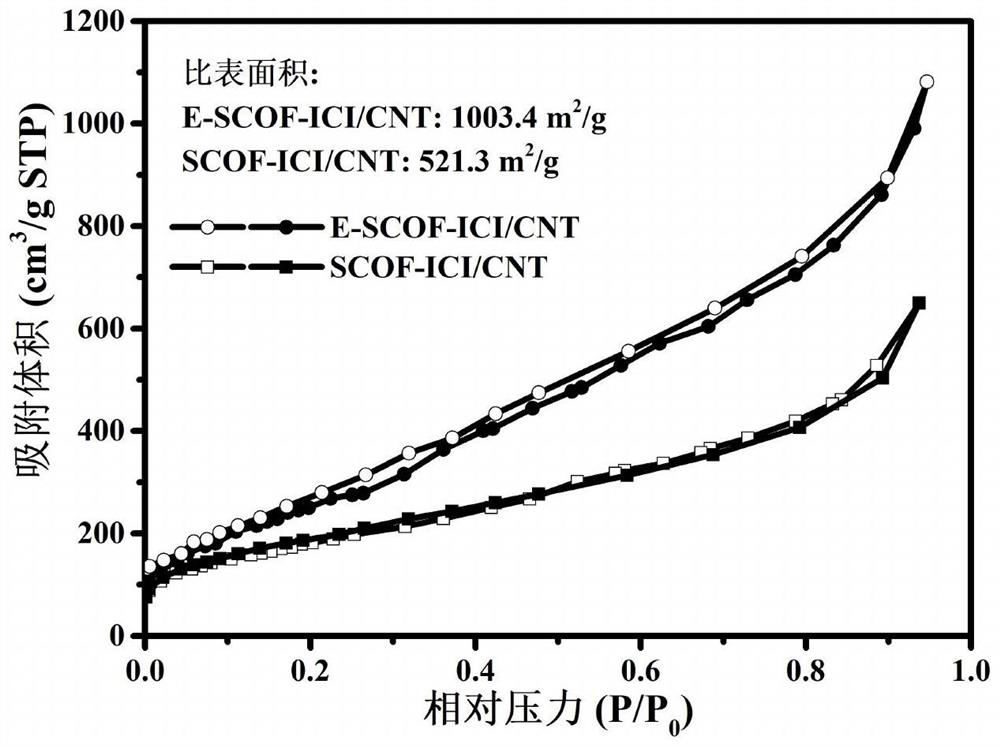

[0036] In this example, a preparation method of a heteroatom-containing covalent organic framework electrode material, a two-dimensional imine-based covalent organic framework material E-SCOF-ICI / CNT loaded with nitrogen-containing heteroatoms on the surface of carbon nanotubes , the steps are as follows:

[0037] a. Dissolve 72 mg of 1,3,5-tris(4-aminophenyl)benzene (TAPB), 40 mg of terephthalaldehyde (PDA), and 40 mg of carbon nanotubes (CNT) in 10.0 mL of 1,4-bis In the mixed solvent of oxane and mesitylene, the volume ratio of 1,4-dioxane and mesitylene solution in the mixed solvent is 4:1, stir for 30min; then add 6.0mg catalyst Sc(OTf)3 and stirred for 1 h to obtain a gray-green solution; finally, wash and centrifuge at least 2 times with methanol and tetrahydrofuran (THF); and dry at 60°C for 24 h to obtain a gray-green SCOF-ICI / CNT powder, thereby obtaining a COF / CNT composite Material;

[0038] b. The above-mentioned COF / CNT composite material is peeled off by mechan...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, and the special feature is that the following synthetic processes are different:

[0048] a. Dissolve 72 mg of 1,3,5-tris(4-aminophenyl)benzene (TAPB), 40 mg of terephthalaldehyde (PDA), and 8 mg of carbon nanotubes (CNT) in 10.0 mL of 1,4-bis In the mixed solvent of oxane and mesitylene, the volume ratio of 1,4-dioxane and mesitylene solution in the mixed solvent is 4:1, stir for 30min; then add 3.0mg catalyst Sc(OTf) 3 and stirred for 1 h to obtain a gray-green solution; finally, wash and centrifuge 3 times with methanol and tetrahydrofuran (THF); and dry at 60°C for 24 h to obtain a gray-green SCOF-ICI / CNT powder, thereby obtaining a COF / CNT composite material ;

[0049] b. The above-mentioned COF / CNT composite material is peeled off by mechanical grinding method to obtain the final heteroatom-containing covalent organic framework electrode material, and 30 mg of COF / CNT composite material is put into a ball mil...

Embodiment 3

[0051] The present embodiment is basically the same as the previous embodiment, and the special feature is the difference in the following synthesis process:

[0052] a. Dissolve 72 mg of 1,3,5-tris(4-aminophenyl)benzene (TAPB), 40 mg of terephthalaldehyde (PDA), and 48 mg of carbon nanotubes (CNT) in 10.0 mL of 1,4-bis In the mixed solvent of oxane and mesitylene, the volume ratio of 1,4-dioxane and mesitylene solution in the mixed solvent is 1:1, stir for 30min; then add 10.0mg catalyst Sc(OTf) 3 and stirred for 1 h to obtain a gray-green solution; finally, wash and centrifuge 3 times with methanol and tetrahydrofuran (THF); and dry at 60°C for 24 h to obtain a gray-green SCOF-ICI / CNT powder, thereby obtaining a COF / CNT composite material ;

[0053] b. The above-mentioned COF / CNT composite material is peeled off by mechanical grinding method to obtain the final heteroatom-containing covalent organic framework electrode material, and 30 mg of COF / CNT composite material is pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com