Laser-welded compressor shell body and welding method thereof

A compressor shell and laser welding technology, which is applied to laser welding equipment, welding equipment, mechanical equipment, etc., can solve the problems of welding slag around the welding surface of the shell, limited production capacity, and high cost, so as to improve the appearance quality of the product and reliability, the welding joint is small and uniform, and the effect of eliminating burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

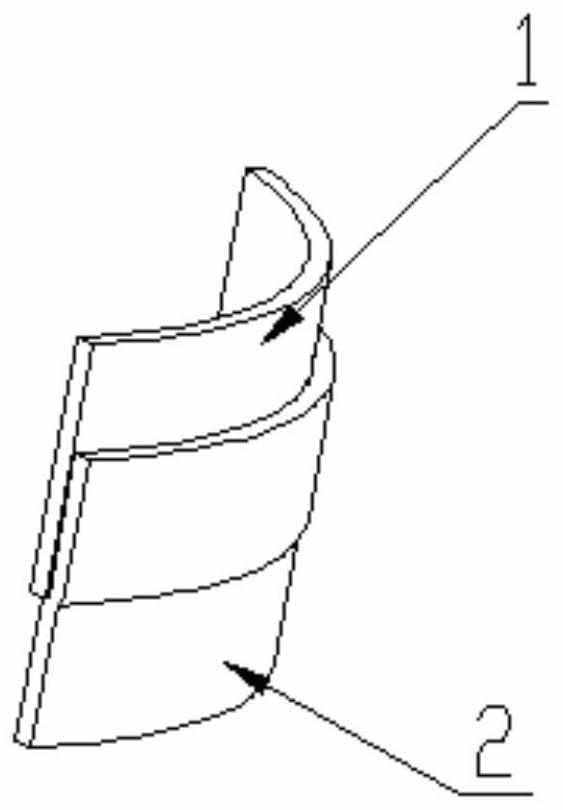

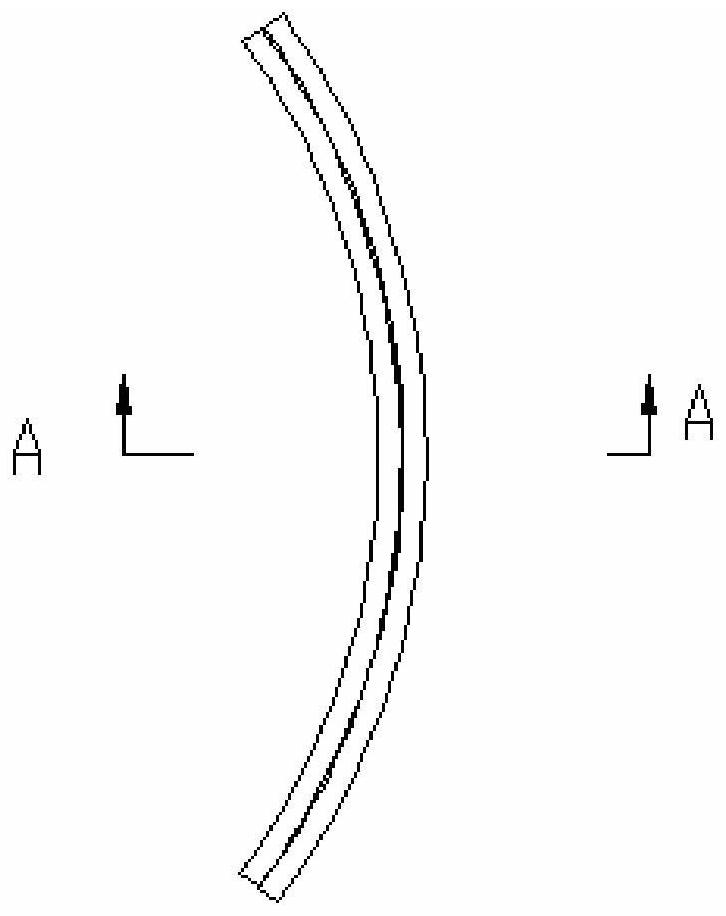

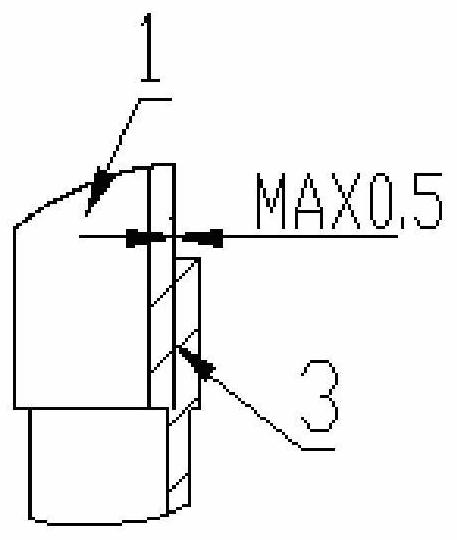

[0058] Such as Figure 1 to Figure 4 and Figure 9 Shown: a laser welded compressor casing, the shape of the upper cover 1 and the lower casing 2 is oval on the cross-section where the upper cover 1 and the lower casing 2 are connected; mouth fit; the maximum clearance of the said seam fit is 0.5mm.

[0059] The weld pool 3 formed by the upper cover 1 and the lower shell 2 has a maximum penetration depth of 1.8mm, and a maximum fusion height 4 of 1.2mm.

[0060] The height of the seam fit is 8.5-9.5 mm. The stop structure is adopted to ensure the accuracy of the position during the welding process.

[0061] The upper cover 1 forms a weld seam 3 through the matching gap formed with the lower casing 2. When the welding seam 3 formed by the matching gap formed between the upper cover 1 and the lower casing 2 is at most 0.5mm, the laser gun head 7 is pumped with the optical fiber and The focused high-energy laser spot formed by conduction will cooperate with the melting of the...

Embodiment 2

[0068] Such as Figure 5 , Figure 6 and Figure 9 Shown: a laser-welded compressor shell, including a lower shell 2 and an upper cover 1 matched with it, the shape of the connecting section of the upper cover 1 and the lower shell 2 is elliptical; The upper cover 1 and the lower case 2 adopt a spigot fit; the maximum gap of the spigot fit is 0.4 mm; the lower case 2 is provided with a maximum depth on the edge of the upper cover 1 Chamfering of the seam of the lower shell not exceeding 1.2mm and width not exceeding 0.15mm5.

[0069] The weld pool 3 formed by the upper cover 1 and the lower shell 2 has a maximum penetration depth of 2.1mm, and a maximum fusion height 4 of 1.5mm.

[0070] The height of the seam fit is 8.5-9.5mm. The stop structure is adopted to ensure the accuracy of the position during the welding process.

[0071] The upper cover 1 forms a welding seam 3 through the matching gap formed with the lower casing 2. When the maximum depth of the lower casing 2...

Embodiment 3

[0078] Such as Figure 7 , Figure 8 and Figure 9 Shown: a laser-welded compressor shell, including a lower shell 2 and an upper cover 1 matched with it, the shape of the connecting section of the upper cover 1 and the lower shell 2 is elliptical; The upper cover 1 and the lower case 2 adopt a spigot fit; the maximum gap of the spigot fit is 0.4 mm; the lower case 2 is provided with a maximum depth on the edge of the upper cover 1 R arc 6 of the seam of the lower shell not exceeding 1.4mm and width not exceeding 0.15mm.

[0079] The weld pool 3 formed by the upper cover 1 and the lower shell 2 has a maximum penetration depth of 2.3mm, and a maximum fusion height 4 of 1.6mm.

[0080] The height of the seam fit is 8.5-9.5mm. The stop structure is adopted to ensure the accuracy of the position during the welding process.

[0081] The upper cover 1 forms a weld 3 through the matching gap formed with the lower casing 2. When the maximum depth of the lower casing 2 does not ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com