Preparation method of N-containing graphdiyne material

A technology of graphyne and alkyne compound, which is applied in the field of preparation of N-containing graphyne materials, and can solve problems such as high equipment and condition requirements, unfavorable promotion and application of N-containing graphyne materials, and disordered distribution of nitrogen elements in graphyne , to achieve the effect of low equipment requirements, broad industrial application prospects, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Adding pyrazine and calcium carbide with a molar ratio of 1:5 into the reaction vessel, then adding absolute ethanol (the addition of ethanol should not exceed the sample), and then under the condition of argon protection, normal temperature and ultrasonic frequency of 53KHz Ultrasonic reaction for 12 hours, the reaction was terminated, separated, the collected solid was first washed with dilute nitric acid with a concentration of 1mol / L to remove unreacted calcium carbide, the obtained solid was dried at 60°C, ground, and the obtained solid was washed with ethanol to obtain The unreacted pyrazine was removed, and the obtained solid was dried again at 60° C. and ground to obtain powdery N-containing graphyne.

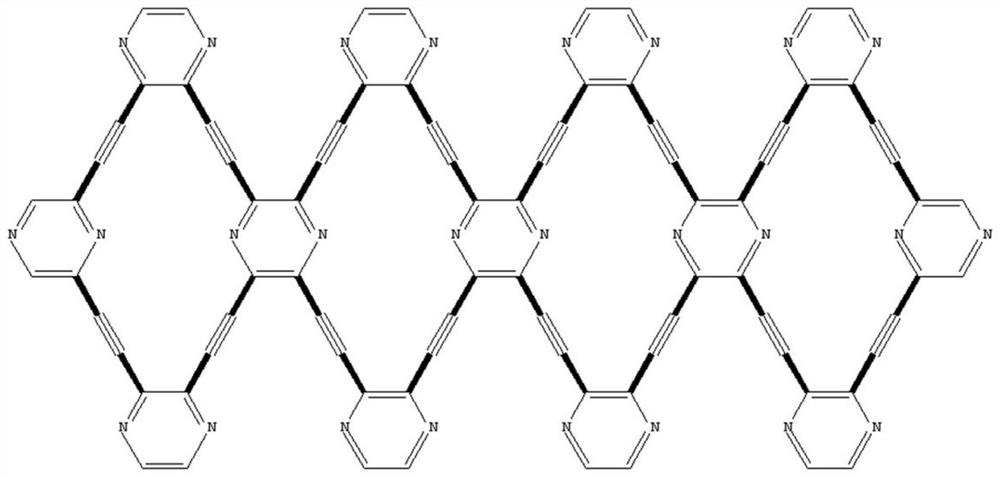

[0030] figure 1 The structural diagram of the N-containing graphyne obtained in this embodiment, as can be seen from the figure, the nitrogen elements are arranged in an orderly manner in the two-dimensional structure;

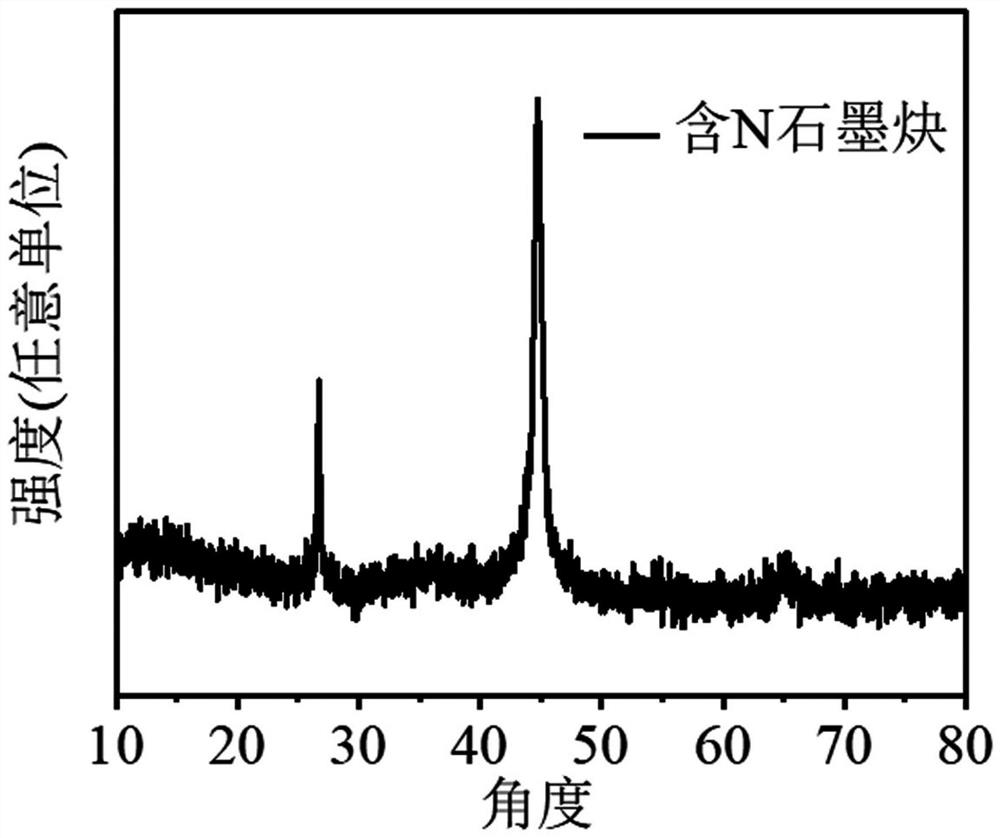

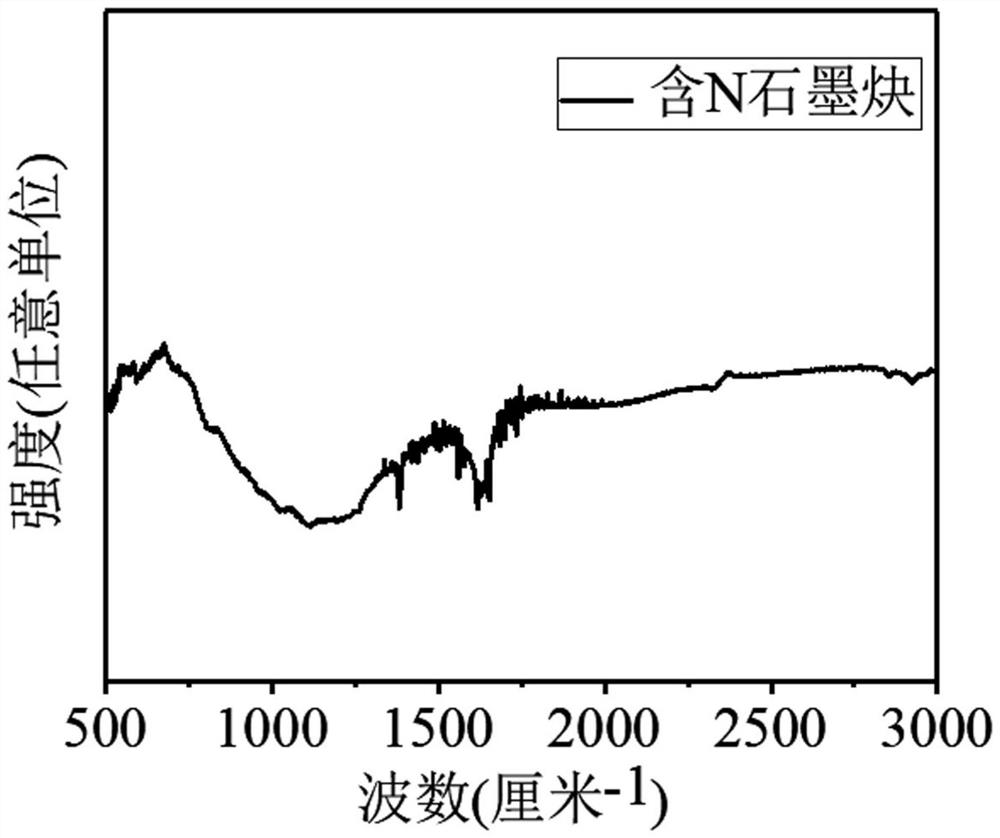

[0031] figure 2 The X-ray diffraction e...

Embodiment 2

[0034] Adding pyrazine and calcium carbide with a molar ratio of 1:10 into the reaction vessel, then adding absolute ethanol (the amount of ethanol added should not exceed the sample), and then under the condition of argon protection, normal temperature and ultrasonic frequency of 53KHz Ultrasonic reaction for 12 hours, the reaction was terminated, separated, the collected solid was first washed with dilute nitric acid with a concentration of 1mol / L to remove unreacted calcium carbide, the obtained solid was dried at 70°C, ground, and the obtained solid was washed with ethanol to obtain Unreacted pyrazine was removed, and the obtained solid was dried again at 70° C. and ground to obtain powdery N-containing graphyne.

[0035] The N-containing graphdiyne prepared by the present embodiment is tested for hydrogen evolution performance:

[0036] Add 20 mg of the N-containing graphyne obtained in this example into a hydrothermal reaction kettle, then add 5 sheets of nickel foam tha...

Embodiment 3

[0039] In the reaction vessel, add pyrazine and calcium carbide with a molar ratio of 1:15, then add absolute ethanol (the amount of ethanol should not exceed the sample), and then under the condition of argon protection, normal temperature and ultrasonic frequency of 53KHz Ultrasonic reaction for 12 hours, the reaction was terminated, separated, the collected solid was first washed with dilute nitric acid with a concentration of 1mol / L to remove unreacted calcium carbide, the obtained solid was dried at 80°C, ground, and the obtained solid was washed with ethanol to obtain The unreacted pyrazine was removed, and the obtained solid was dried again at 80° C. and ground to obtain powdery N-containing graphyne.

[0040] The N-containing graphdiyne prepared by the present embodiment is tested for energy storage performance:

[0041] The N-containing graphyne, conductive agent (acetylene black) and binder (polytetrafluoroethylene dispersion) prepared in this example were added to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com