Tegafur-L-proline eutectic and preparation method thereof

A technology of proline and tegafur, which is applied in the field of tegafur-L-proline co-crystal, can solve the problems of co-crystal stability and unsatisfactory dissolution rate, and achieve good chemical stability and good solubility , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

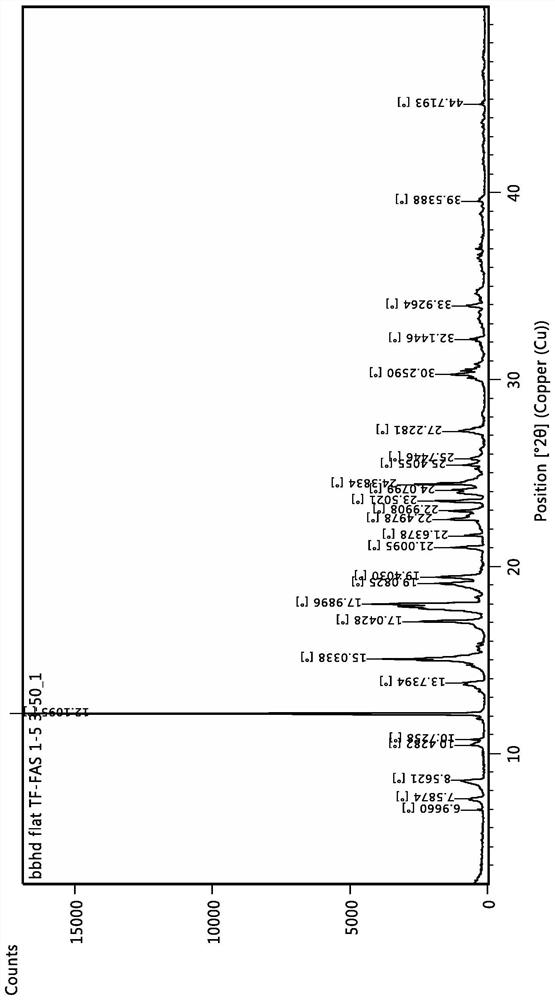

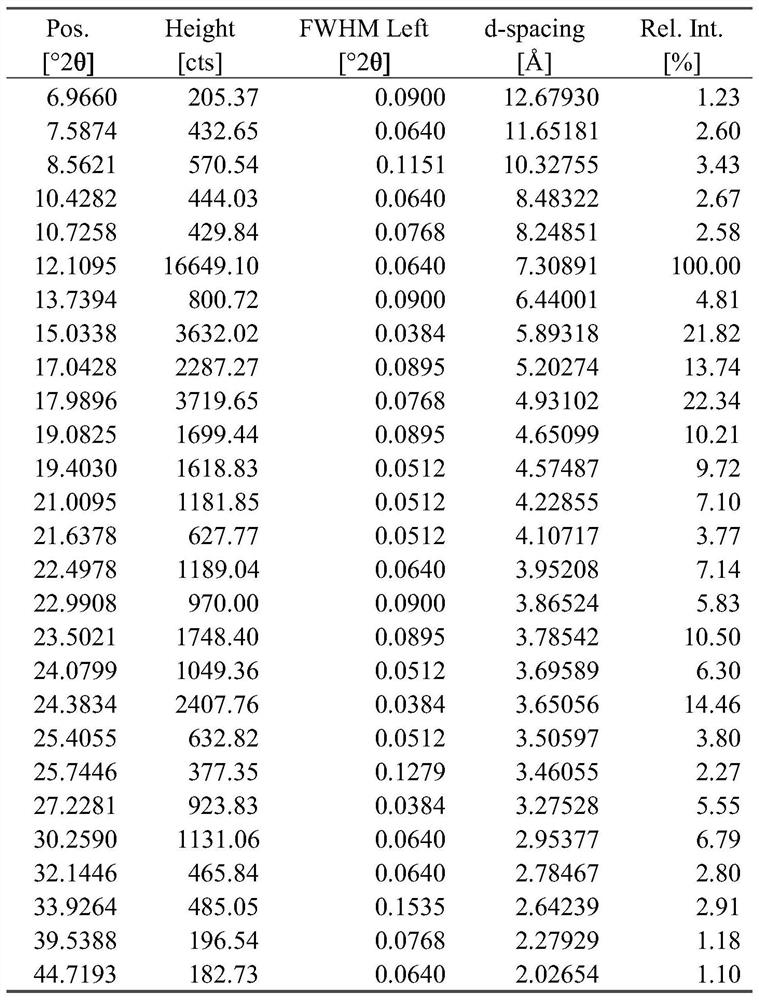

Embodiment 1

[0058] Dissolve 200mg of tegafur in 10ml of acetone solvent, 150mg of L-proline in 10ml of ethanol solvent, then mix the two solvents and heat to 50°C. After the solution is clarified, stir and react for 8 hours, then slowly cool down to 10~ After 15°C, stand for crystallization under temperature control for 58 hours, filter, wash the filter cake with propanol, and vacuum-dry Tegafur-L-proline cocrystal at 55°C for 10 hours. The yield is 93.23%, and the purity is 99.94%.

Embodiment 2

[0060] Dissolve 200mg of tegafur in 2.5ml of acetonitrile solvent, 138mg of L-proline in 3ml of ethanol solvent, then mix the two solvents and heat to 40°C. After the solution is clarified, stir and react for 10 hours, then slowly cool down to 5 After ~10°C, stand for crystallization under temperature control for 48 hours, filter, wash the filter cake with ethanol, and vacuum-dry Tegafur-L-proline cocrystal at 45°C for 12 hours. The yield is 92.22%, and the purity is 99.92%.

Embodiment 3

[0062] Dissolve 200mg of Tegafur in 3ml of acetone and 3ml of methanol mixed solvent, and 161mg of L-proline in 8ml of ethanol solvent, then mix the two solvents and heat to 60°C, stir the solution for 5 hours after clarification, then cool down slowly After reaching 15-20°C, set the temperature to stand and crystallize for 65 hours, filter, wash the filter cake with methanol, and vacuum-dry Tegafur-L-proline cocrystal at 60°C for 8 hours. The yield is 92.29%, and the purity is 99.93%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com