Radiation refrigeration coating with gradient structure as well as preparation method and application thereof

A radiative cooling, gradient structure technology, applied in coatings, reflective/signal coatings, devices for coating liquids on surfaces, etc., can solve problems such as hidden dangers of material stability, mismatch, performance compromise, etc. Anti-peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

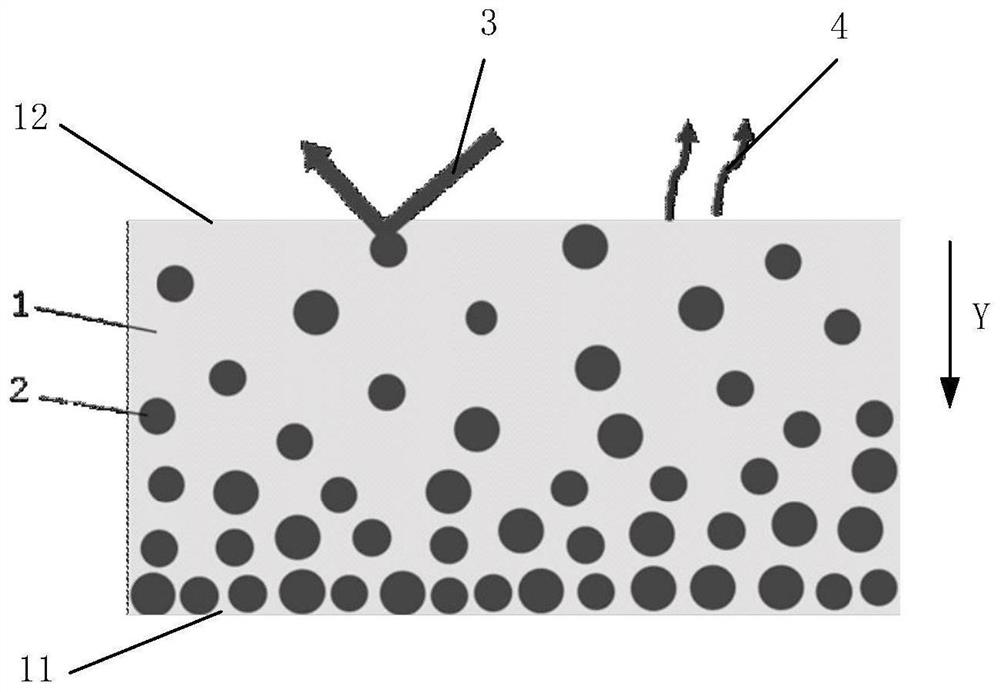

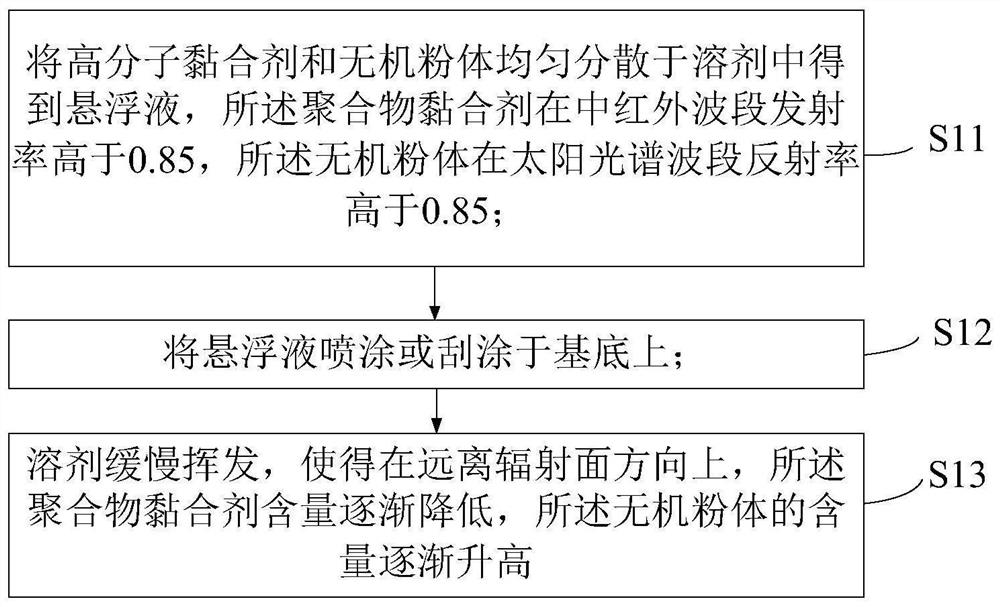

[0035] figure 2 It is a flowchart of a method for preparing a radiation cooling coating with a gradient structure provided by an embodiment of the present invention, such as figure 2 Shown, this preparation method comprises:

[0036] S11. Uniformly disperse the polymer binder and the inorganic powder in a solvent to obtain a suspension, the emissivity of the polymer binder in the mid-infrared band (2.5-25 μm) is higher than 0.85, and the inorganic powder is in the solar spectrum band (0.3~2.5μm) the reflectivity is higher than 0.85;

[0037] S12, spraying or scraping the suspension on the substrate;

[0038] S13. The solvent volatilizes slowly, so that in the direction away from the radiation surface, the content of the polymer binder gradually decreases, and the content of the inorganic powder gradually increases.

[0039] At room temperature, the polymer binder dissolves in the solvent to form small-sized molecular chains, which can migrate upwards with the volatilizati...

Embodiment 1

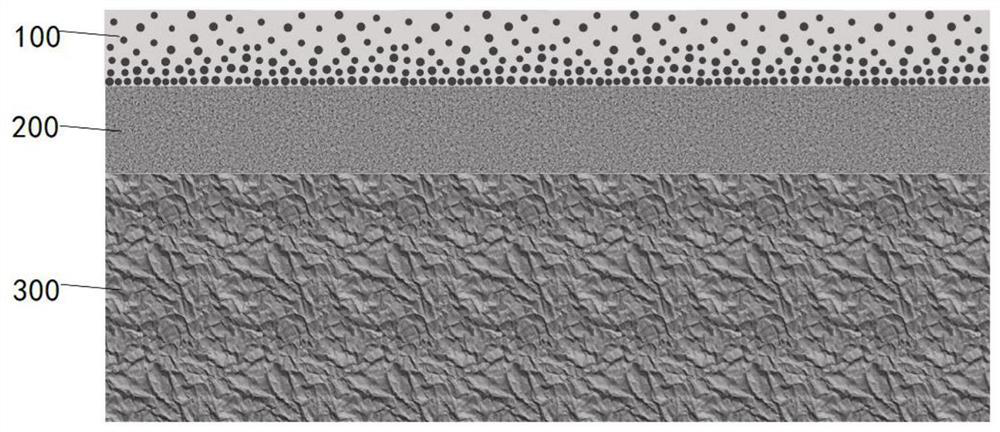

[0046] The coating described in this example consists of BaSO 4 , PVB composition. Among them, PVB: BaSO 4 The mass ratio is 1:5, BaSO 4 The average particle size is 0.5μm; coating radiation surface to adhesion surface PVB:BaSO 4 The volume ratio gradually transitions from 2:1 to 1:10.

[0047] The coating preparation process is as follows: the BaSO 4 , PVB is dispersed in a certain volume of solvent in proportion, and then treated with a homogenizer for 30 minutes to obtain a uniform suspension. The volume fraction of the solvent in the suspension is 50%; the solvent is a mixture of water and ethanol, wherein the volume ratio of water and ethanol is 1:9. Brush the suspension on a glass plate with a coater, and dry it at room temperature for 1 hour to form a coating with a thickness of about 500 μm. During the drying process, the solvent volatilization induces the migration of the polymer binder to the radiant side exposed to the air, thereby forming a gradient structure...

Embodiment 2

[0050] The coating described in this example consists of BaSO 4 , PVB composition. Among them, PVB: BaSO 4 The mass ratio is 1:5, BaSO 4 The average particle size is 0.5μm; coating radiation surface to adhesion surface PVB:BaSO 4 The volume ratio gradually transitions from 5:1 to 1:20.

[0051] The coating preparation process is as follows: the BaSO 4 , PVB is dispersed in a certain volume of solvent in proportion, and then treated with a homogenizer for 30 minutes to obtain a uniform suspension. The volume fraction of the solvent in the suspension is 65%; the solvent is a mixture of water and ethanol, wherein the volume ratio of water and ethanol is 2:8. Use a coating machine to brush the suspension on a glass plate, and dry it at room temperature for 1.5 hours to form a coating with a thickness of about 500 μm. In this example, the higher the solvent content, the longer the evaporative drying time, thus inducing the formation of a more pronounced gradient structure.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com