High-safety composite positive plate, preparation method thereof and applied lithium ion battery

A technology of lithium-ion batteries and composite positive electrodes, which is applied in the field of lithium-ion batteries, can solve problems such as ineffective inhibition of battery chain reactions, and achieve the effects of avoiding battery thermal runaway, reducing heat production, and inhibiting heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

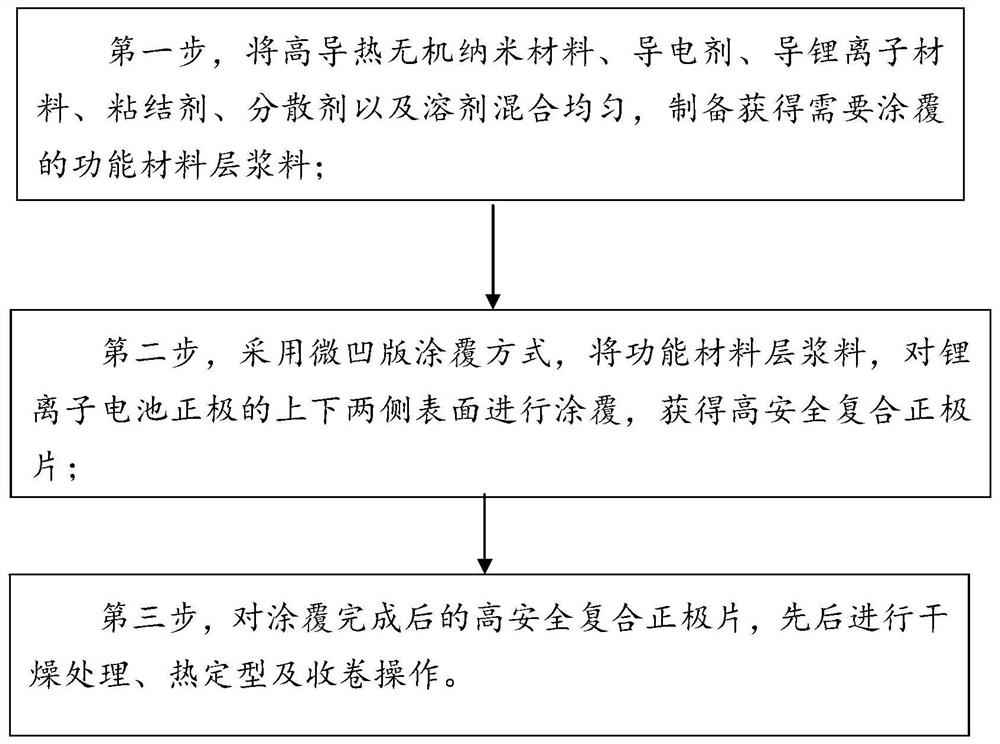

[0075] In order to prepare the high-safety composite positive electrode sheet provided by the present invention above, see figure 1 As shown, the present invention also provides a method for preparing a high-safety composite positive electrode sheet, comprising the following steps:

[0076] In the first step, the high thermal conductivity inorganic nanomaterials, conductive agents, lithium ion conductive materials, binders, dispersants and solvents are evenly mixed to prepare the functional material layer slurry to be coated;

[0077] In the second step, the functional material layer slurry is applied to the positive electrode of the lithium-ion battery (the positive electrode of the lithium-ion battery is an existing positive electrode sheet comprising a positive electrode active material layer, and the positive electrode active material layer is coated on the positive electrode by using a micro-gravure coating method. The upper and lower sides of the current collector) are c...

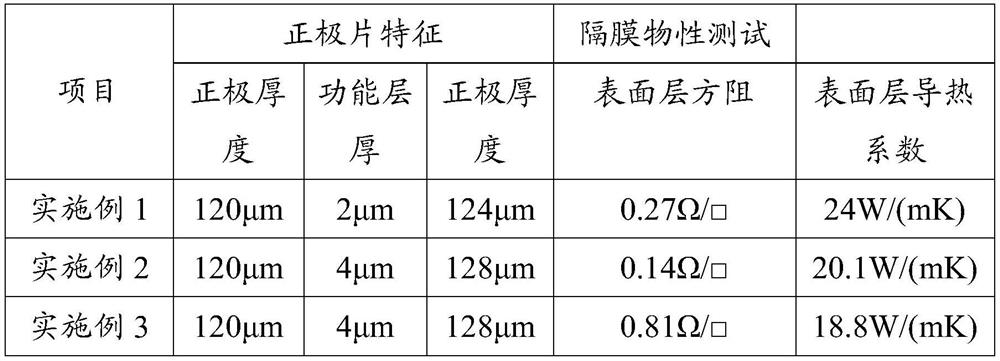

Embodiment 1

[0109] The preparation method of a kind of high-safety composite positive plate provided by the present invention and the lithium-ion battery used for it, the steps are as follows:

[0110]The first step, the preparation of the lithium-ion battery positive electrode (i.e. the existing common battery positive plate), the positive electrode ratio is, NCM811 (positive electrode active material): conductive agent (carbon black): binder (PVDF) = 95:2 :3.

[0111] The second step is the preparation of the functional material layer, using inorganic thermally conductive nanomaterials (hexagonal boron nitride), LLZO, CNT, binder PVDF, dispersant PVP, solvent NMP, etc. to prepare coating slurry. The percentage by weight of solid raw materials for the coating slurry is as follows: 60% for inorganic nano heat-conducting material, 20% for LLZO, 5% for CNT, 10% for binder, and 5% for dispersant. The solvent of the slurry is NMP, and the solid content of the slurry is 10%. Use a centrifuga...

Embodiment 2

[0117] The invention provides a method for preparing a high-safety composite positive electrode sheet and a lithium-ion battery applied thereto. The steps are as follows:

[0118] The first step is the preparation of the lithium-ion battery positive electrode (that is, the existing common battery positive electrode sheet), the positive electrode ratio is LCO: conductive agent (carbon black): binder (PVDF) = 95:2:3.

[0119] The second step is the preparation of the functional material layer, using inorganic thermally conductive nanomaterials (mixed materials of hexagonal boron nitride and alumina), LATP, graphene, binder PTFE, dispersant PVP, solvent NMP, etc. to prepare coating slurry . The percentage by weight of solid raw materials for the coating slurry is as follows: 30% for inorganic nano-thermal conductive materials, 50% for LATP, 3% for graphene, 12% for binders, and 5% for dispersants. The solvent of the slurry is NMP, and the solid content of the slurry is 10%. Use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com