Production technology of ham slices and ham slices

A production process and technology of ham slices, applied in the production process of ham slices and the field of ham slices, to achieve the effects of good elasticity, simplified processing, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

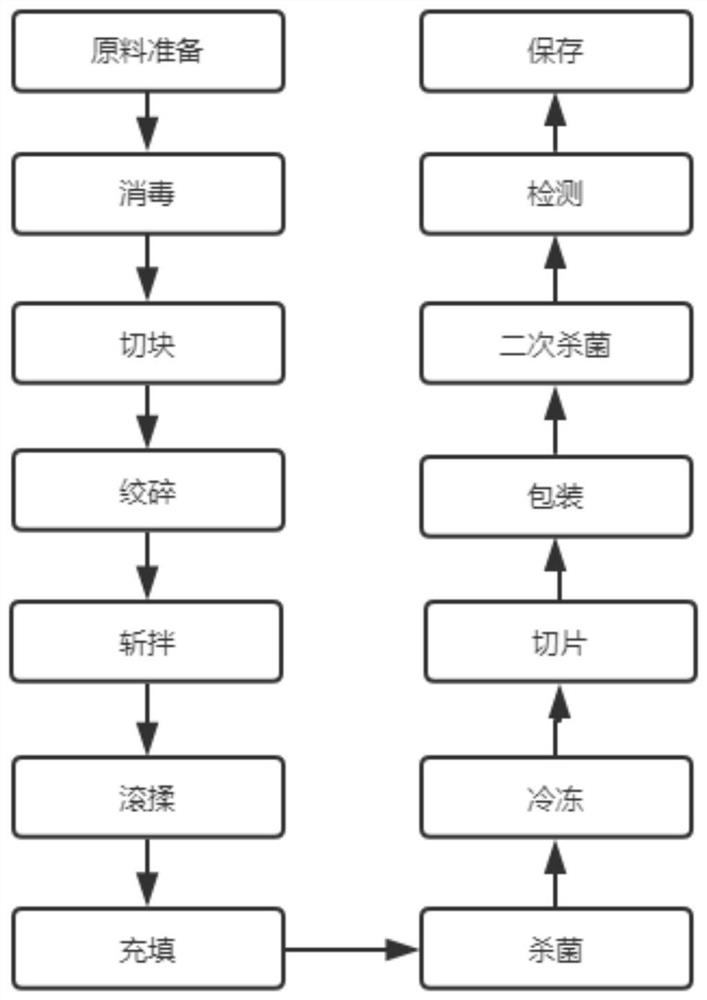

[0055] A sliced ham, such as figure 1 As shown, it includes the following percentage composition: 68% of raw materials, 5% of marinade, 0.01% of pyrophosphate, 8% of starch, 12% of borneol, 1% of refined salt, 5% of protein, some fiber casings and the balance of ice water.

[0056] Described raw material is fresh pork, beef lean meat and fat meat, and fat fat is best with pig back fat.

[0057] The preparation method of described marinade comprises the steps:

[0058] S31: Add 20kg of tap water into the salt water preparation device;

[0059] S32: Add 97.99% of refined salt, 1.5% of granulated sugar, 0.5% of sodium nitrite, and 0.01% of tripolyphosphate to mix and dissolve. Tripolyphosphate should be completely dissolved before feeding. If refined salt and granulated sugar are agglomerated, crush them before adding;

[0060] S33: If the concentration of salt water is high, add appropriate amount of borneol to the salt water, depending on the actual situation;

[0061] S34...

Embodiment 2

[0085] A kind of production technology of sliced ham and sliced ham, such as figure 1 As shown, it includes the following percentage composition: 70.99% of raw materials, 5% of marinade, 0.01% of pyrophosphate, 8% of starch, 10% of borneol, 1% of refined salt, 4% of protein, some fiber casings and the balance of ice water.

[0086] Described raw material is fresh pork, beef lean meat and fat meat, and fat fat is best with pig back fat.

[0087] The preparation method of described marinade comprises the steps:

[0088] S31: Add 20kg of tap water into the salt water preparation device;

[0089] S32: Add 97.99% of refined salt, 1.5% of granulated sugar, 0.5% of sodium nitrite, and 0.01% of tripolyphosphate to mix and dissolve. Tripolyphosphate should be completely dissolved before feeding. If refined salt and granulated sugar are agglomerated, crush them before adding;

[0090] S33: If the concentration of salt water is high, add appropriate amount of borneol to the salt wa...

Embodiment 3

[0114] A sliced ham, such as figure 1 As shown, it includes the following percentage composition: 65% of raw materials, 4% of marinade, 0.01% of pyrophosphate, 8% of starch, 10% of borneol, 2% of refined salt, 7% of protein, some fiber casings and the balance of ice water.

[0115] Described raw material is fresh pork, beef lean meat and fat meat, and fat fat is best with pig back fat.

[0116] The preparation method of described marinade comprises the steps:

[0117] S31: Add 20kg of tap water into the salt water preparation device;

[0118] S32: Add 97.99% of refined salt, 1.5% of granulated sugar, 0.5% of sodium nitrite, and 0.01% of tripolyphosphate to mix and dissolve. Tripolyphosphate should be completely dissolved before feeding. If refined salt and granulated sugar are agglomerated, crush them before adding;

[0119] S33: If the concentration of salt water is high, add appropriate amount of borneol to the salt water, depending on the actual situation;

[0120] S34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com