Composite catalyst and preparation method and application thereof

A composite catalyst, mixed solution technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of incomplete oxidation, low removal efficiency, etc., to achieve increased concentration, low preparation cost, The effect of improving the efficiency of oxidation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

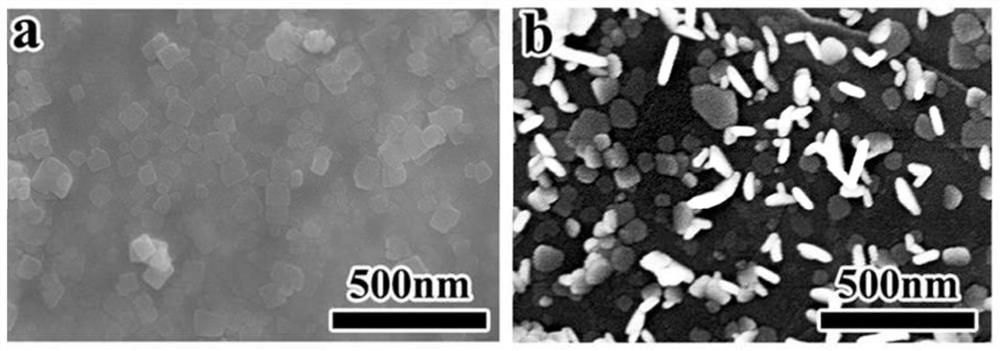

[0025] Embodiment 1: Preparation of GO-BiOCl (001) composite catalyst

[0026] 1) Disperse 4mg of graphene oxide (GO) into 10mL of absolute ethanol, add 40mg of polyvinylpyrrolidone into the above solution, and disperse by ultrasonic for 10min. Then remove the supernatant under the rotating speed condition of 7000r / min, and redisperse the sediment in the absolute ethanol of 10ml;

[0027] 2) 93mg of Bi(NO 3 ) 3 ·5H 2 O is dissolved in the mannitol solution (1mol / L), magnetically stirred and dispersed to obtain a mixed solution of 10mL;

[0028] 3) After mixing the two solutions obtained in step 1) and step 2) evenly, slowly add 5 mL of saturated sodium chloride solution, and stir at room temperature for 20 min;

[0029] 4) Transfer the mixed solution to a hydrothermal kettle, and heat it in water at 160°C for 3 hours. After the temperature returns to room temperature, centrifuge at 7000r / min, wash with ethanol and deionized water for 4 times, and place in a blast Dry in a...

Embodiment 2

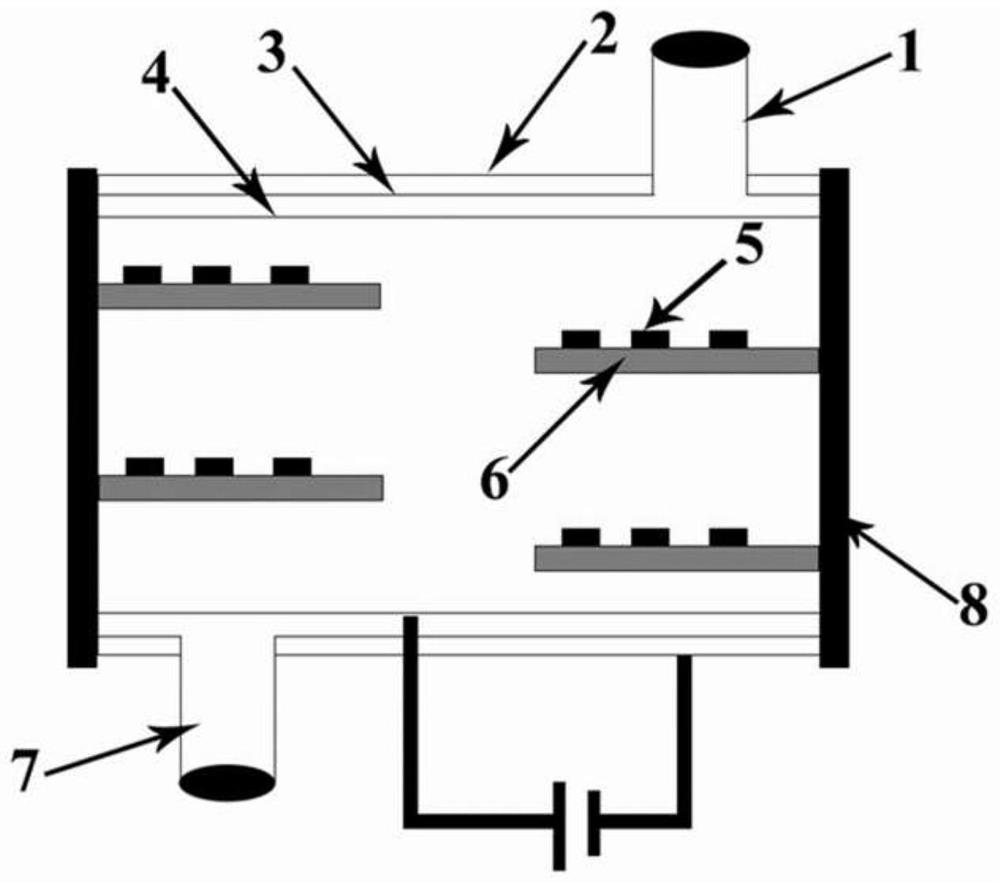

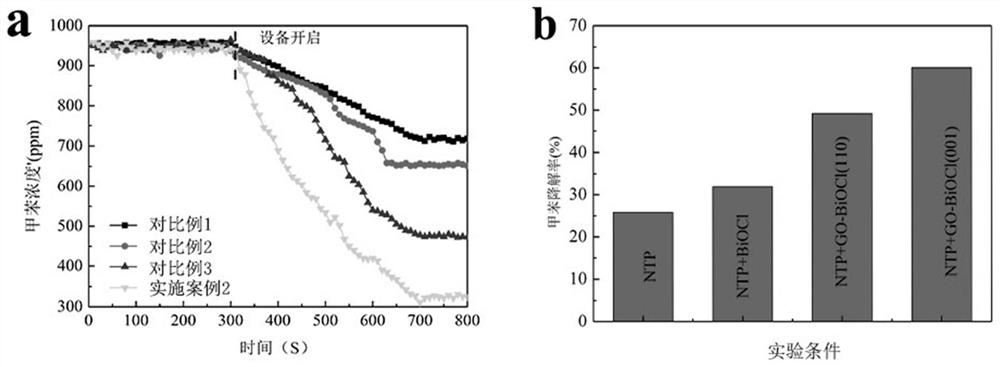

[0036] Embodiment 2: under the action of low-temperature plasma, the application of the composite catalyst synthesized in oxidation VOCs:

[0037]Toluene was selected as the experimental model, and the low temperature plasma technology (NTP) composite catalyst was used to degrade VOCs. Using the working principle of dielectric barrier discharge, the NTP reactor is designed. The coiled stainless steel mesh is placed on the inside and outside of the quartz tube, and connected to the external high-voltage AC power supply (Y16J12516) as the positive and negative electrodes of the discharge. Take 2-10 mg of the synthesized composite photocatalyst and disperse it into 5-20 μL of ethanol solution, then add 5-20 μL of naphthol, disperse evenly and spread it on a 1cm×4cm ITO conductive glass, dry it at 40-80℃ for later use . According to this method, the catalyst is fixed on the ITO conductive glass, as follows figure 2 As shown, alternately immobilized inside the reaction chamber o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com