Single-layer double-sided asymmetric porous radiation cooling film as well as preparation method and application thereof

An asymmetric, double-sided technology, applied in the field of passive cooling materials, can solve the problems of increased weight, high cost, complex operation process of support structure and high requirements, and achieve the effect of high solar reflectance, high and middle infrared radiation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a single-layer double-sided asymmetric porous radiation cooling film. A non-solvent-induced phase separation method is used to obtain a cellulose acetate porous polymer substrate material with a micron-scale pore structure. The directional enrichment of the micron oxide particles is adjusted on one side of the cellulose acetate porous polymer base material, and a single-layer double-sided asymmetric porous radiation cooling film is prepared.

[0030] Specifically include the following steps:

[0031] Step 1, configure acetone / water solution, acetone / N,N-dimethylacetamide solution, tetrahydrofuran / water solution or tetrahydrofuran / N,N-dimethylacetamide solution in a beaker, and stir at a speed of 100rpm to 1000rpm to make The solution is mixed evenly to obtain a dissolved solution;

[0032] Step 2, weighing an appropriate amount of cellulose acetate powder, adding it to the dissolved solution in step 1, and continuing to sti...

Embodiment 1

[0044] Weigh the reagents according to the stoichiometric ratio: 60mL of acetone, 5mL of distilled water, and stir at a speed of 400rpm by magnetic stirring to make the solution evenly mixed; Stir at a high speed for 4 hours to obtain a clear and transparent solution; add 0.5 g of silicon dioxide powder with a particle size of 8 μm to the clear and transparent solution, and continue stirring for 4 hours to obtain a milky white suspension; pour the milky white solution into a glass petri dish with a diameter of 10 cm. Naturally volatilized and dried in a fume hood for 12 hours to obtain a white single-layer double-sided asymmetric porous radiation cooling film.

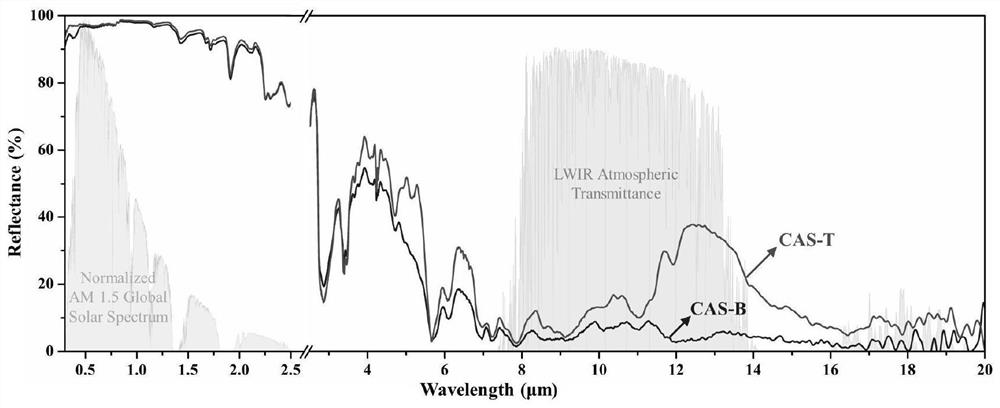

[0045] Such as figure 1 As shown, the radiation cooling film material prepared in this example can achieve a good cooling effect: the solar reflectance of the film in the 0.3-2.5 micron band is as high as 0.96, and the mid-infrared radiation rate in the 8-13 micron atmospheric window band is as high as 0.95; Compared ...

Embodiment 2

[0047] Weigh the reagents according to the stoichiometric ratio: 100mL of acetone, 30mL of N,N-dimethylacetamide, and stir at a speed of 1000rpm by magnetic stirring to mix the solution evenly; then weigh 8g of cellulose acetate powder, add the above In the acetone / N,N-dimethylacetamide solution, continue to stir at a speed of 1000rpm for 10h to obtain a clear and transparent solution; add 2.4g of magnesium oxide powder with a particle size of 8μm to the clear and transparent solution, and continue to stir for 10h to obtain a milky white suspension solution; the milky white solution was poured into a glass petri dish with a diameter of 10 cm, and was naturally volatilized and dried in a fume hood for 24 hours to obtain a white single-layer double-sided asymmetric porous radiation cooling film.

[0048] The radiation cooling film material prepared in this embodiment can achieve a good cooling effect: the solar reflectance of the film in the 0.3-2.5 micron band is as high as 0.93...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com