Protective film and preparation method thereof, and lithium ion battery using protective film

A lithium-ion battery and protective film technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., to achieve the effects of improved thermal diffusion, high weather resistance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

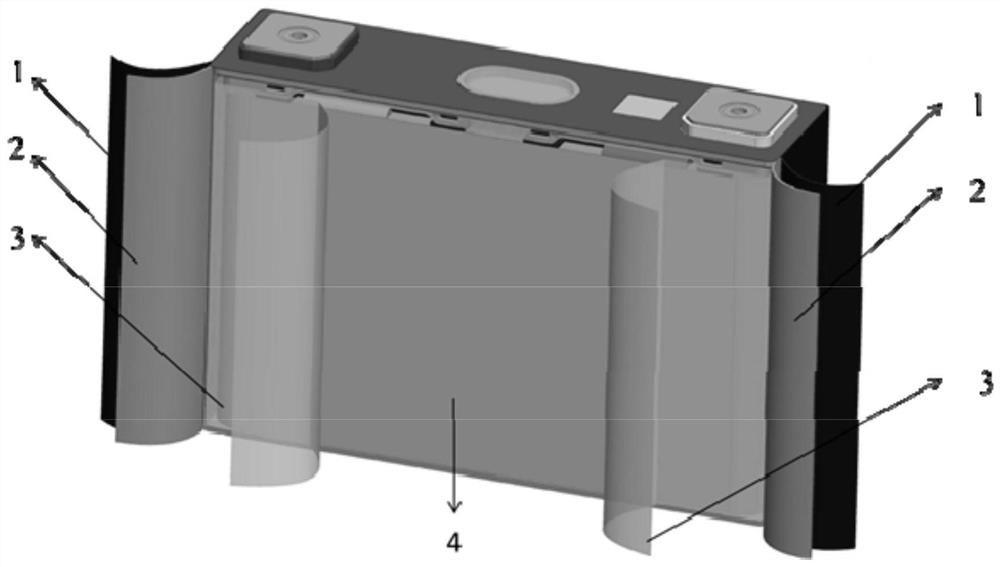

Image

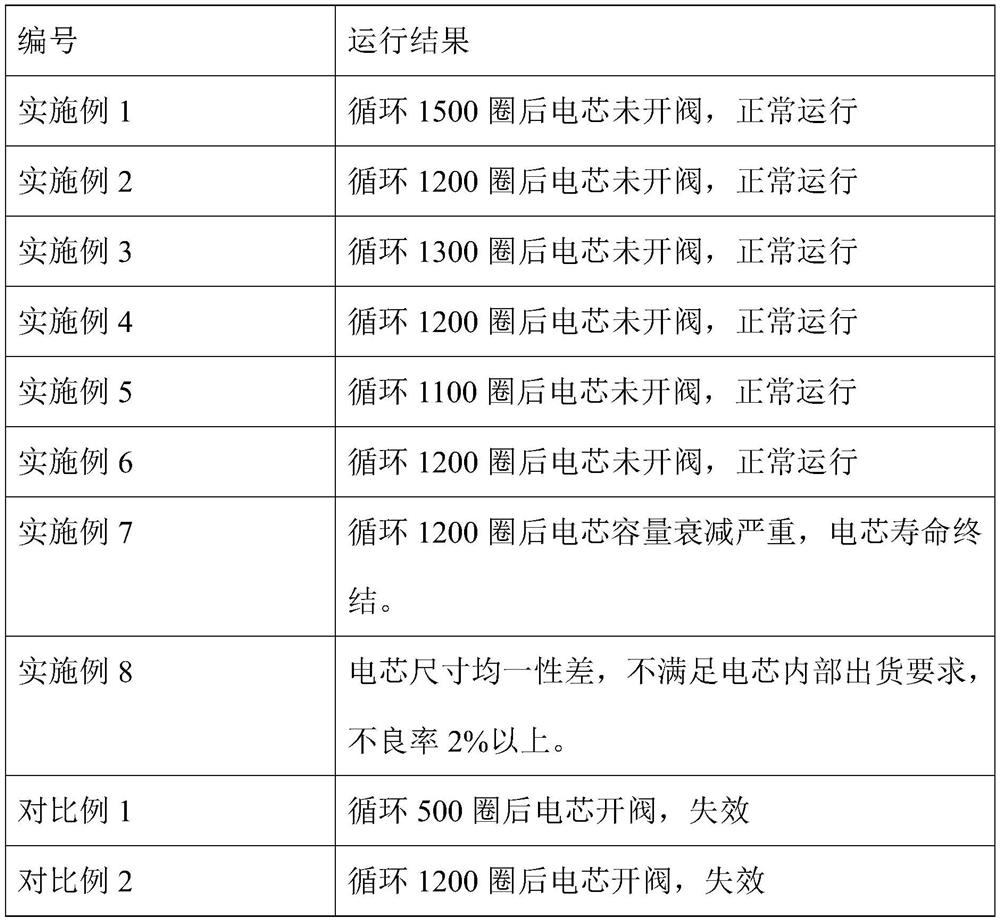

Examples

Embodiment 1

[0052] This embodiment provides a protective film, the protective film is composed of a base film and a coating on one side of the base film, the coating includes a binder polytetrafluoroethylene and an insulating material titanium dioxide, the insulating material and adhesive The mass ratio of the binder is 0.6:1, the material of the base film is polypropylene, the thickness of the protective film is 70 μm, and the thickness of the base film is 50 μm.

[0053] This embodiment also provides a method for preparing the above-mentioned protective film, the specific steps of which are:

[0054] 1) First, mix polyvinylidene fluoride and N-methylpyrrolidone in a mixing tank at a mass ratio of 1:16 at 25°C to make a uniform binder solution;

[0055] 2) Then, add the magnesium oxide to the glue in 1), wherein the mass ratio of the glue to magnesium oxide is 1:0.6, and mix evenly at 30° C. to obtain a slurry;

[0056] 3) Coating the slurry onto the prepared 50 μm thick polypropylene i...

Embodiment 2

[0061] This embodiment provides a protective film, the protective film is composed of a base film and coatings on both sides of the base film, the coating includes adhesive polyacrylic acid and insulating material zinc oxide, the insulating material and adhesive The mass ratio of the agent is 0.4:1, the material of the base film is polyethylene terephthalate, the thickness of the protective film is 100 μm, and the thickness of the base film is 80 μm.

[0062] This embodiment also provides a method for preparing the above-mentioned protective film, the specific steps of which are:

[0063] 1) Firstly, polyacrylic acid (solid content: 49%) emulsion and water were stirred and mixed uniformly in a stirring tank at 35° C. in a mass ratio of 1:2 to prepare a uniform binder solution;

[0064] 2) Then, add the zinc oxide to the glue in 1), wherein the mass ratio of the glue to zinc oxide is 1:0.4, and mix evenly at 35° C. to obtain a slurry;

[0065] 3) Apply the slurry to the prepar...

Embodiment 3

[0068] This embodiment provides a protective film, the protective film is composed of a base film and a coating on one side of the base film, the coating includes a binder polytetrafluoroethylene and an insulating material titanium dioxide, the insulating material and adhesive The mass ratio of the binder is 1:1, the material of the base film is polyimide, the thickness of the protective film is 150 μm, and the thickness of the base film is 120 μm.

[0069] This embodiment also provides a method for preparing the above-mentioned protective film, the specific steps of which are:

[0070] 1) First, the polytetrafluoroethylene (40% solid content) emulsion and absolute ethanol were stirred and mixed uniformly at 15° C. in a stirring tank at a mass ratio of 1:1 to prepare a uniform binder solution;

[0071] 2) Then add the titanium dioxide to the glue solution in 1), wherein the mass ratio of the glue solution to titanium dioxide is 1:1, and mix evenly at 10° C. to obtain a slurry;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com