Active welding flux for tungsten inert gas argon arc welding of hull steel and preparation method and use method thereof

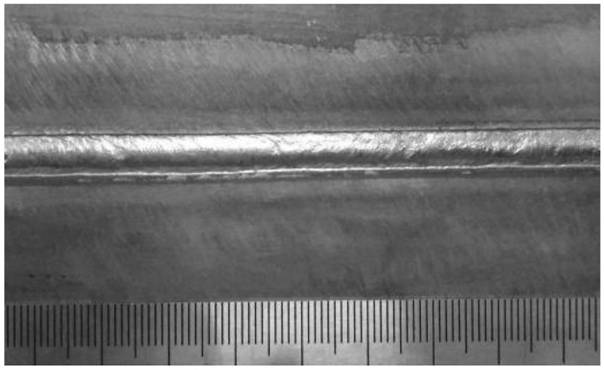

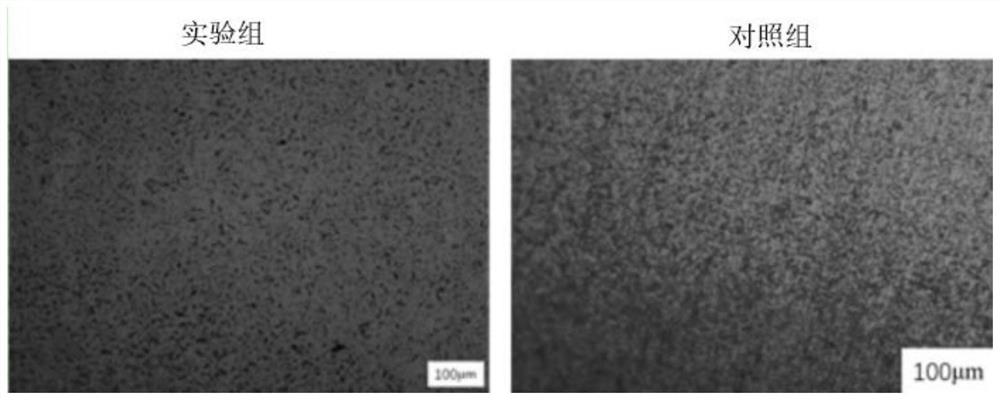

A tungsten inert gas, active flux technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve problems such as blanks, and achieve the effect of no pores, improved efficiency, and good forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

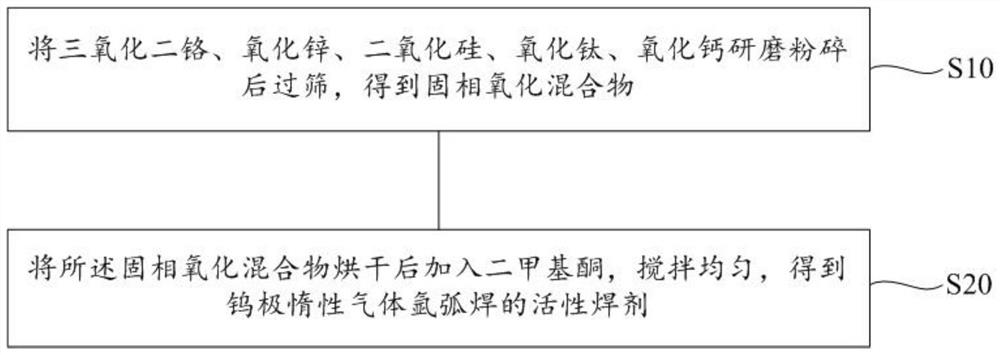

[0028] See figure 1 The present invention also proposes a preparation method of active flux for marine steel tungsten inert gas argon arc welding, comprising the following steps:

[0029] S10: Grinding and pulverizing chromium trioxide, zinc oxide, silicon dioxide, titanium oxide, and calcium oxide, and then sieving to obtain a solid phase oxidation mixture.

[0030] S11: In this step, manual grinding or mechanical grinding can be used, for example: Weigh chromium trioxide, zinc oxide, silicon dioxide, titanium oxide, and calcium oxide according to the mass parts of the raw materials and put them into the mortar together Grinding into powder, and then using a sieve with a pore size of less than 74 microns to screen the ground powder, so that the particle size of the ground solid phase oxide is less than 74 microns.

[0031] S12: Put the solid-phase oxidation mixture into a drying room with a relative humidity of 40% for 2h-3h.

[0032] S20: After drying the solid-phase oxid...

Embodiment 1

[0036] Put 30% chromium trioxide, 25% zinc oxide, 15% silicon dioxide, 25% calcium oxide plus titanium oxide into a grinding vessel and grind to powder, and then use a sieve with a pore size of less than 74 microns to grind the ground The powder is screened so that the particle size of the ground solid phase oxide is less than 74 microns; the solid phase oxidation mixture is placed in a drying room with a relative humidity of 40% for 2 hours; the dried solid phase oxidation mixture is placed in a container , evenly add 5% dimethyl ketone, in the process of adding dimethyl ketone, constantly stir the solid phase oxidation mixture and dimethyl ketone, so that the mixture of the two is adjusted to a paste, and the marine steel tungsten of the present invention is obtained Active flux for argon arc welding with extremely inert gases.

Embodiment 2

[0038] Put 27% chromium trioxide, 27% zinc oxide, 16% silicon dioxide, 24% calcium oxide plus titanium oxide into a grinding vessel and grind them into powder, and then use a sieve with a pore size of less than 74 microns to grind Screen the powder so that the particle size of the ground solid phase oxide is less than 74 microns; put the solid phase oxidation mixture into a drying room with a relative humidity of 40% for 2.5 hours; put the dried solid phase oxidation mixture into In the container, add 6% dimethyl ketone evenly, and in the process of adding dimethyl ketone, constantly stir the solid-phase oxidation mixture and dimethyl ketone, so that the mixture of the two is adjusted to a paste, and the marine ketone of the present invention is obtained. Active flux for tungsten inert gas argon arc welding of steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com