A kind of preparation method of aliphatic dihydric alcohol

An aliphatic diol, hydration reaction technology, applied in the field of organic synthesis, can solve the problems of high reaction water ratio, low product selectivity, large energy consumption, etc., to simplify the process flow, reduce the reaction water ratio, save energy and The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

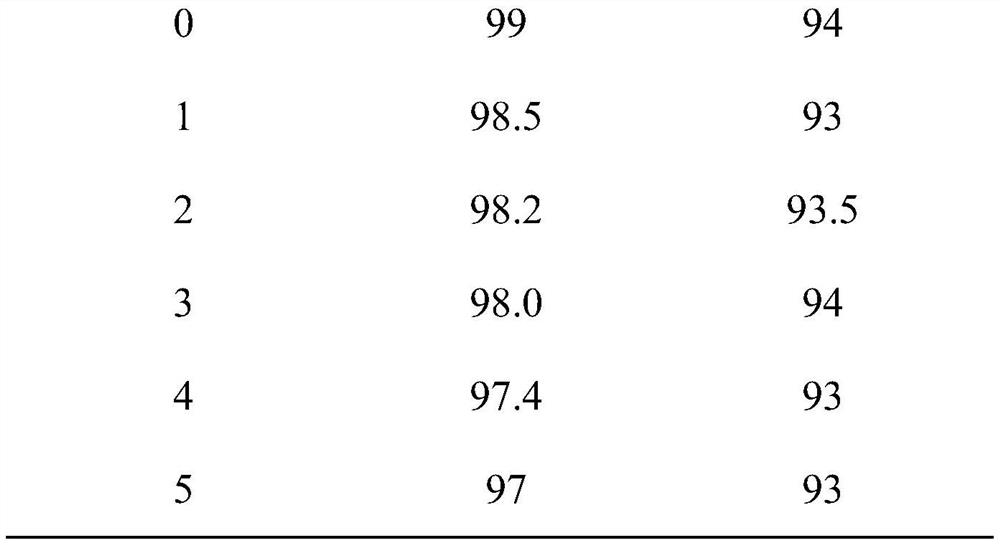

[0035] In an autoclave with a capacity of 1000 milliliters and equipped with a stirrer, thermometer and pressure gauge, add a certain molar ratio of alkylene oxide and water, 0.1-1% organic acid surfactant and 5-20% organic acid surfactant based on the mass of alkylene oxide % solid phosphoric acid catalyst, filled with nitrogen to keep the pressure at 2-30bar (gauge pressure), raise the reaction temperature to 90-150°C, keep the rotating speed at 500 rpm, and react for 0.5-4 hours. After the reaction was finished, it was cooled to room temperature, and the reaction liquid was analyzed qualitatively and quantitatively by gas chromatography to calculate the conversion rate of alkylene oxide and the selectivity of dihydric alcohol products. The ratio of raw materials, reaction conditions and reaction results in the reaction process are shown in Table 1. The catalyst was recovered by filtration, washed with ethanol and water, and then vacuum-dried for use.

Embodiment 9-10

[0037] Loading 10g of solid phosphoric acid particles into a stainless steel fixed-bed reactor with an inner diameter of 8 mm and a length of 300 mm, mixing the raw material hexane with 2-10 times the molar amount of water and 0.1-1% mass of dodecanoic acid, Use a metering pump according to the liquid space velocity of 0.5-1h -1 Feed material, react under the conditions of reaction pressure 0.2-3MPa, hot spot temperature 90-150℃ to prepare hexanediol, use gas chromatography to conduct qualitative and quantitative analysis of the product, calculate the conversion rate of hexanediol and the selectivity of hexanediol, the reaction conditions And the results are shown in Table 1.

Embodiment 11

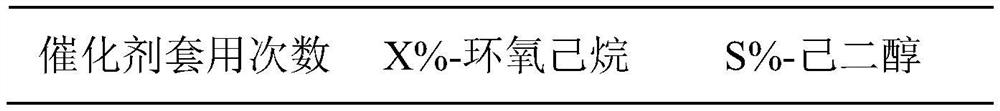

[0039] The fresh solid phosphoric acid catalyst is replaced by a reclaimed catalyst, and other reaction conditions are the same as in Example 1, and the reaction results are as follows.

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com