Preparation method of epsilon-N lauroyl lysine

A technology of lauroyl lysine and lysine, which is applied to the preparation of carboxylic acid amides, the preparation of organic compounds, chemical instruments and methods, etc., which can solve the problems of low yield, many steps required for purification, and interference of by-product subsequent treatment Large and other problems, to achieve the effect of simple steps, increase reaction yield, and optimize synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

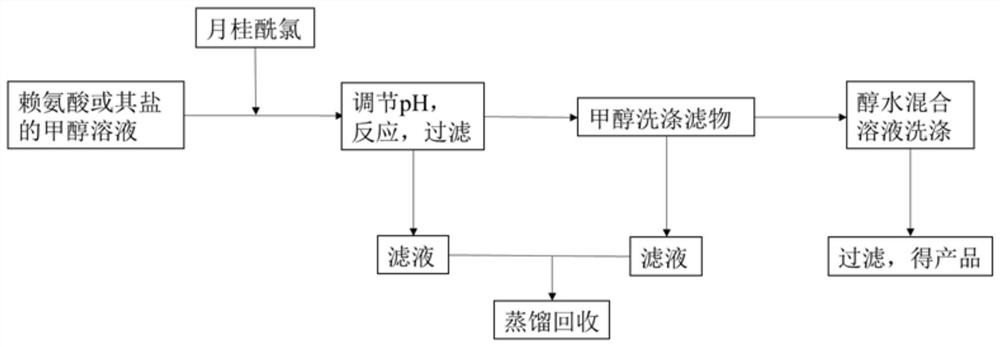

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of ε-N lauroyl lysine, the specific preparation steps are as follows:

[0027] At 20°C, add 5g of lysine and 100mL of methanol to the flask, then add 15g of lauroyl chloride, adjust the pH value of the mixture to 9 with sodium hydroxide, stir and react for 2h, after the reaction stops, dilute the reaction solution with hydrochloric acid Adjust the pH value to 7, filter, wash the filtrate with 50mL of methanol, and filter again, then wash and filter the filtrate with methanol aqueous solution to obtain a high-purity product with a purity of >98.5%. Combine three methanol filtrates to be distilled, recover methanol, and then release time can continue to use.

Embodiment 2

[0029] A preparation method of ε-N lauroyl lysine, the specific preparation steps are as follows:

[0030] At 40°C, add 10g of lysine and 100mL of methanol to the flask, then add 20g of lauroyl chloride, adjust the pH of the mixture to 9 with potassium hydroxide, and stir for 2 hours. After the reaction stops, dilute the reaction solution with glacial acetic acid Adjust the pH value to 7, filter, wash the filtrate with 50mL of methanol, filter again, then wash and filter the filtrate with aqueous ethanol to obtain a high-purity product with a purity >98%, combine the methanol filtrate and aqueous ethanol twice to be distilled, After recycling, it can be used next time.

Embodiment 3

[0032] A preparation method of ε-N lauroyl lysine, the specific preparation steps are as follows:

[0033] At 50°C, add 10g of lysine and 300mL of methanol to the flask, then add 40g of lauroyl chloride, adjust the pH of the mixture to 10 with sodium hydroxide, and stir for 2 hours. After the reaction stops, adjust the pH of the reaction solution with hydrochloric acid Adjust the value to 8, filter, wash the filtrate in batches with 100mL methanol, filter again, wash and filter the filtrate with aqueous ethanol to obtain a high-purity product with a purity >99%, combine the methanol filtrate and aqueous ethanol to be distilled, and recover You can continue to use it next time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com