Conductive microsphere for anisotropic conductive adhesive/film and preparation method thereof

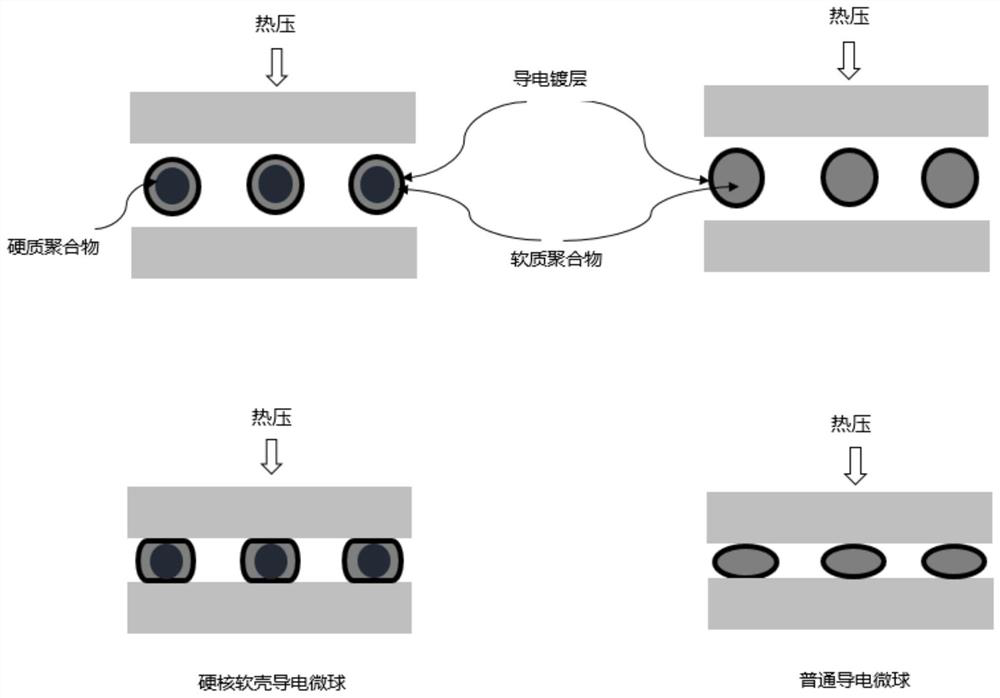

An anisotropic conductive adhesive and microsphere technology, which is applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problems of not being able to improve the conductivity, and achieve the effect of maintaining consistency and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

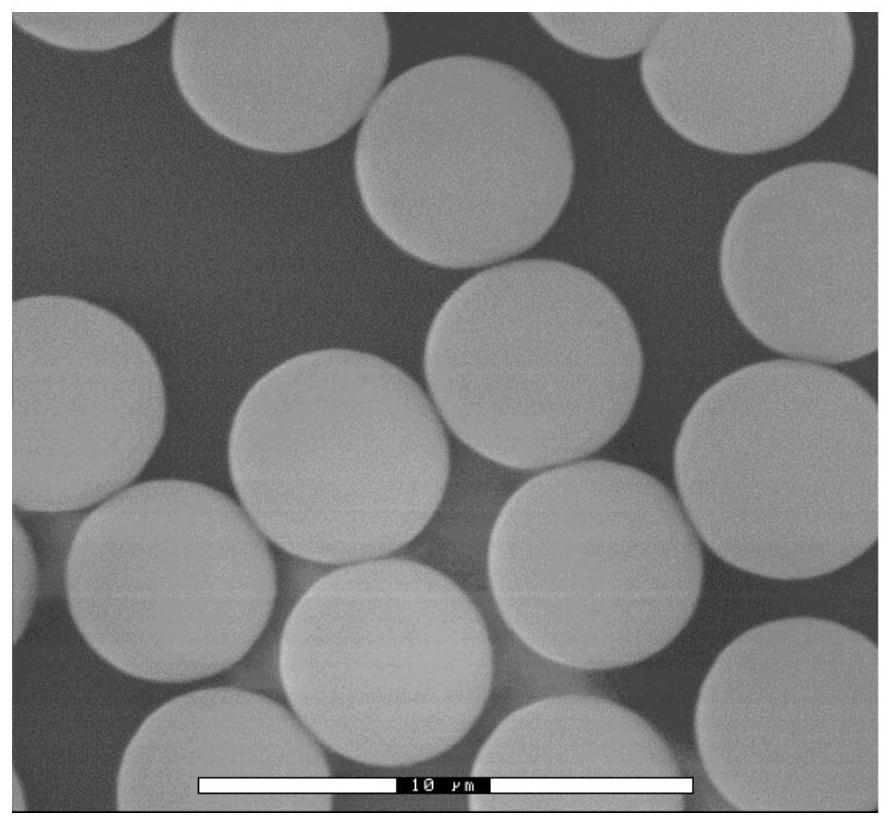

[0093] A conductive microsphere for anisotropic conductive adhesive / film is obtained according to the following steps (the conductive microsphere made by this example is called No. 1 sample):

[0094] (1) Microsphere initiator

[0095] With 2.5 micron microspheres of 25% hydroxyethyl methacrylate and 75% divinylbenzene copolymerization as starting microspheres (the microspheres are the TS025HM microspheres provided by Taizhou Tianshu New Material Technology Co., Ltd., the particle size distribution of the microspheres The coefficient of variation was 3.0%). 20 g of TS025HM microspheres and 9.5 g of triethylamine were added to a 500 ml round bottom flask containing 200 ml of tetrahydrofuran. Under electromagnetic stirring, 20 g of 2-bromopropionyl bromide was added dropwise to the above mixture, and the reaction continued for 12 hours. Filter and wash thoroughly with tetrahydrofuran and methanol. After vacuum drying at 100°C for two hours, the initiator microspheres were obt...

Embodiment 2

[0110] The conductive microsphere made by this example is called No. 2 sample, and other steps are the same as embodiment 1, except that:

[0111] (1) Microsphere initiator

[0112] 2.9-micron microspheres polymerized with 65% divinylbenzene were used as the starting microspheres (the number TS0029-Y microspheres were provided by Taizhou Tianshu New Material Technology Co., Ltd., and the coefficient of variation of the particle size distribution of the microspheres was 2.6%). (A) Add 20 g of TS0029-Y microspheres and 2.0 g of sodium borohydride into a 500 ml round bottom flask containing 200 ml of tetrahydrofuran, and place in an ice bath. 20ml containing 8.0BF 3 g of tetrahydrofuran solution was added dropwise to the above solution, and under electromagnetic stirring, the reaction was continued for 3 hours at room temperature. Then, 20ml of ice water was added to adjust the pH to 8, and then 20ml of 35% hydrogen peroxide was added. Filter and wash thoroughly with tetrahydr...

Embodiment 3

[0115] The conductive microsphere made by this example is called No. 3 sample. Other steps are with embodiment 1, difference is:

[0116] (1) Microsphere initiator

[0117] With 3.0 micron microspheres copolymerized with 25% chloromethylstyrene and 75% divinylbenzene as the starting microspheres, the particle size distribution coefficient of variation of the microspheres is 2.8% (the microspheres are provided by Taizhou Tianshu New Material Technology Co., Ltd. TS003CI microspheres).

[0118] (2) Core-shell microspheres

[0119] 20.0 g of microsphere initiator and 19.0 g of methylstyrene were added to a 1000 ml round bottom flask containing 550 ml of tetrahydrofuran (solution A), and oxygen was removed with nitrogen. Add 1.8g CuBr and 4.0g bipy into a 500ml round bottom flask containing 150ml THF (solution B), and deoxygenate with nitrogen. Add 4.0 g of chloromethyl styrene into a 500 ml round bottom flask containing 250 ml of tetrahydrofuran (solution C), and deoxygenate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com