Lignin-containing bio-based composite material and preparation method thereof

A composite material and lignin technology, which is applied in the field of bio-based composite materials containing lignin and its preparation, can solve the impact of the strength and rigidity of lignin composite materials, the dispersion and compatibility between matrices are not outstanding, and the wood Reduce the environmental protection performance of plain composite materials and other problems, achieve good anti-ultraviolet radiation performance, improve thermal stability, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Preparation of bio-based polyamide polymers

[0075] (1) Add 100g of undecylenic acid methyl ester and 1g of 1,3-diamino-propanol into 4ml of tetrahydrofuran; after passing through argon for half an hour, place it in an oil bath at 40°C, add 10ml of sodium methoxide, React at 40°C for 20 hours, and then recrystallize to obtain a white powdery solid, which is the desired functional polyamide monomer 1;

[0076] (2) Put 54g of functional polyamide monomer 1, 12g of butyric anhydride, and 40mg of dimethylaminopyridine into a round-bottomed flask, add 3ml of tetrahydrofuran to mix, and react at 50°C for 10 hours to obtain a clear solution. The functional polyamide obtained after purification Amide monomer 2;

[0077] (3) Add 1350 mg of functional polyamide monomer 2, 150 mg of functional polyamide monomer 1, 200 mg of oxadithiol, and 10 mg of azobisisobutyronitrile catalyst and 10 ml of tetrahydrofuran into the reaction vessel; feed argon for 15 After that, the mixture wa...

Embodiment 2

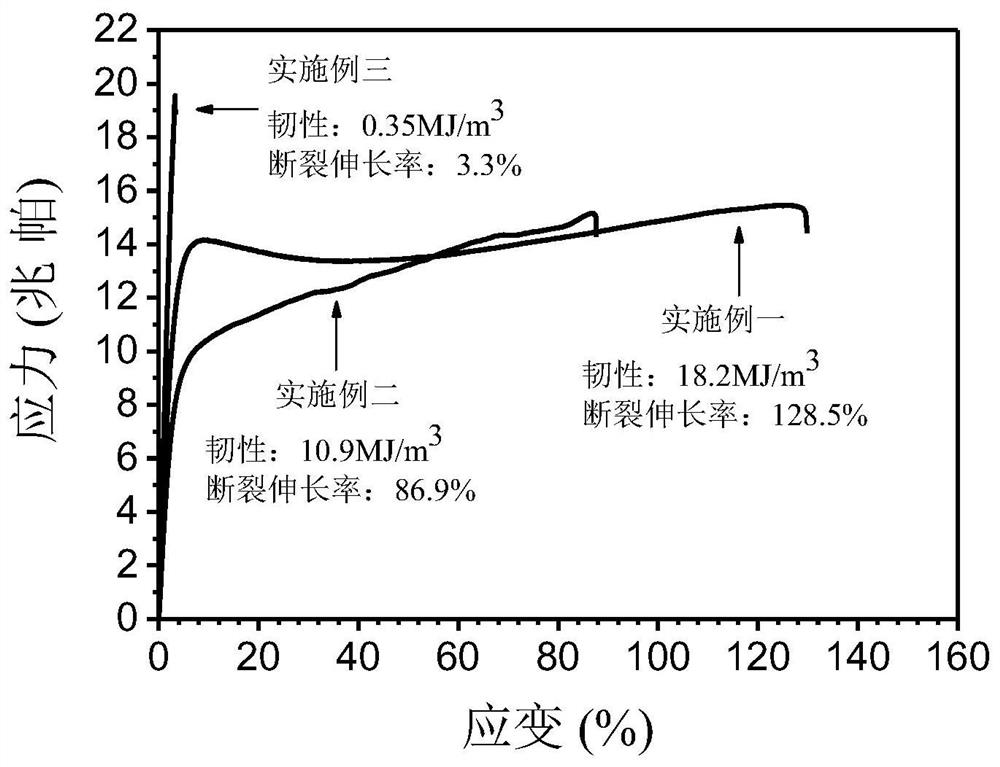

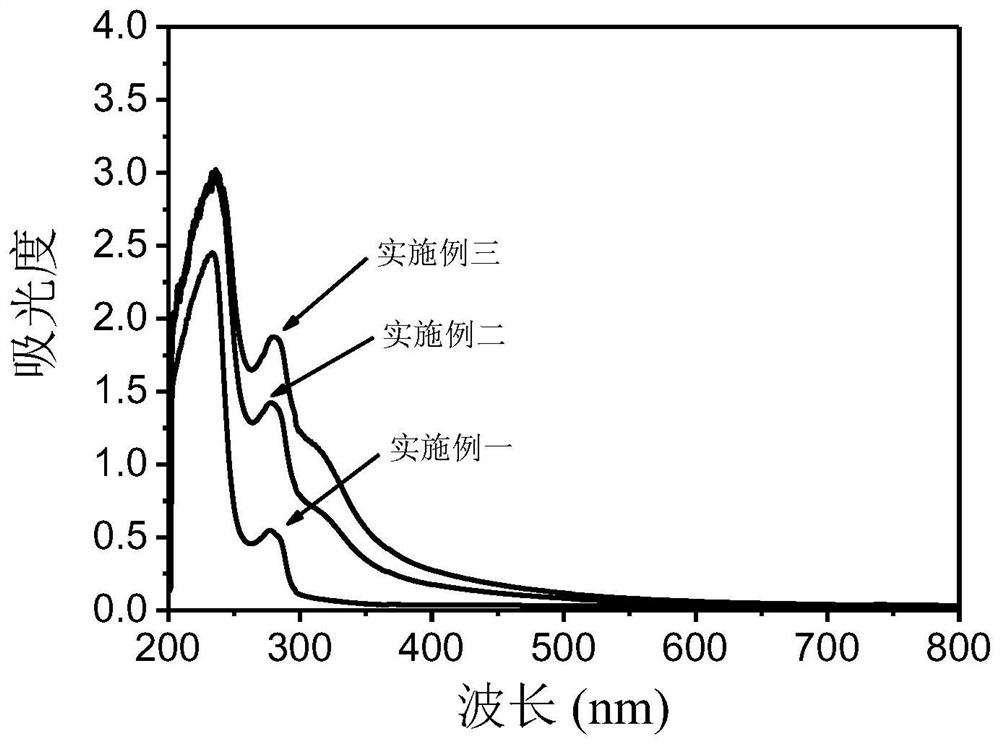

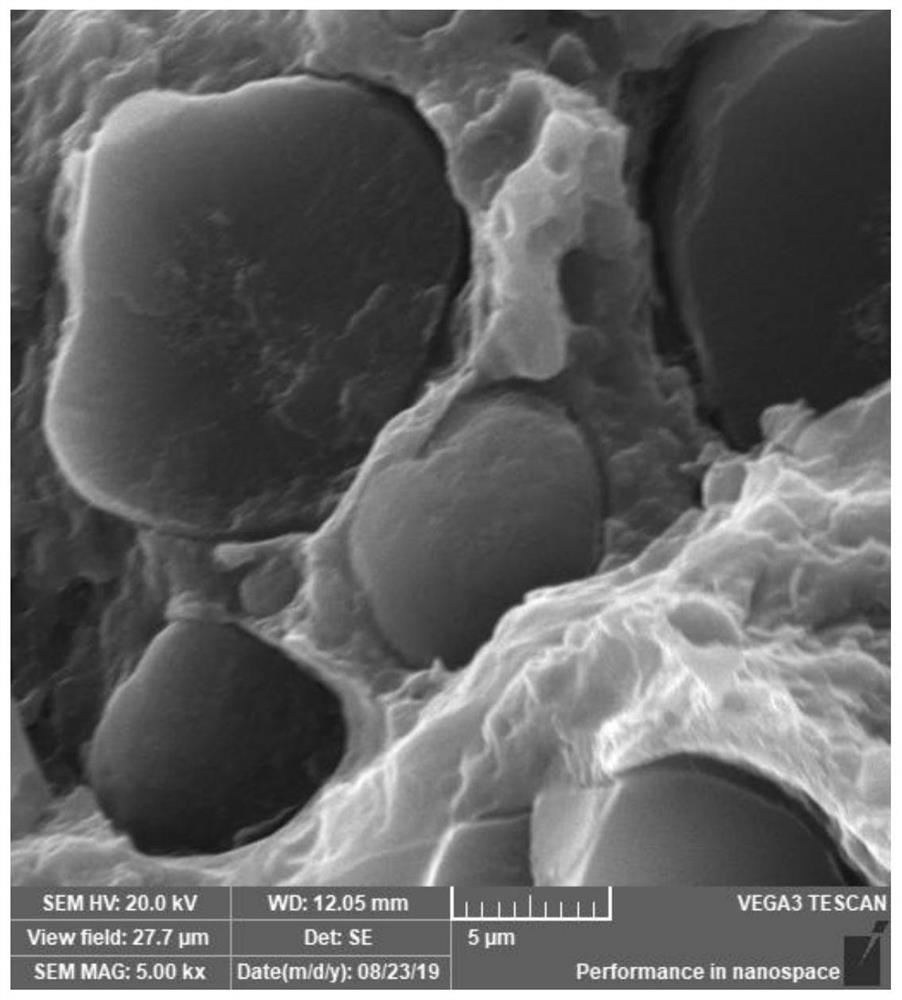

[0080] Preparation method of bio-based composite material containing lignin

[0081] (1) 50 parts by weight of unmodified lignin (not modified by chemical groups of lignin) and 50 parts by weight of the polyamide obtained in Example 1 were dried in a vacuum oven at 60°C for 8h, and set aside ;

[0082] (2) Mix the dried lignin and polyamide in step (1), add them into an internal mixer, and blend them for 10 minutes at 100°C and a speed of 100r / min;

[0083] (3) Put the mixture kneaded in step (2) into a vacuum tablet press, and press it at 150° C. to obtain a bio-based composite material containing lignin.

[0084] Example 2

[0085] Preparation method of bio-based composite material containing lignin

[0086] (1) 60 parts by weight of unmodified lignin and 40 parts by weight of the polyamide obtained in Example 1 were dried in a vacuum oven at 60°C for 8 hours, and set aside;

[0087] (2) Mix the dried lignin and polyamide in step (1), add them into an internal mixer, and...

Embodiment 3

[0090] Preparation method of bio-based composite material containing lignin

[0091] (1) 70 parts by weight of unmodified lignin and 30 parts by weight of the polyamide obtained in Example 1 were dried in a vacuum oven at 60°C for 8 hours, and set aside;

[0092] (2) Mix the dried lignin and polyamide in step (1), add them into an internal mixer, and blend them for 10 minutes at 100°C and a speed of 100r / min;

[0093] (3) Put the mixture kneaded in step (2) in a vacuum tablet press, and press it at 150° C. to obtain a bio-based composite material containing lignin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile toughness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com