Functionalized polyolefin composite diaphragm and preparation method and application thereof

A technology of polyolefin diaphragm and composite diaphragm, which is applied in nanotechnology for materials and surface science, electrical components, nanotechnology, etc., and can solve problems such as poor thermal stability and poor wettability of electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of coating liquid:

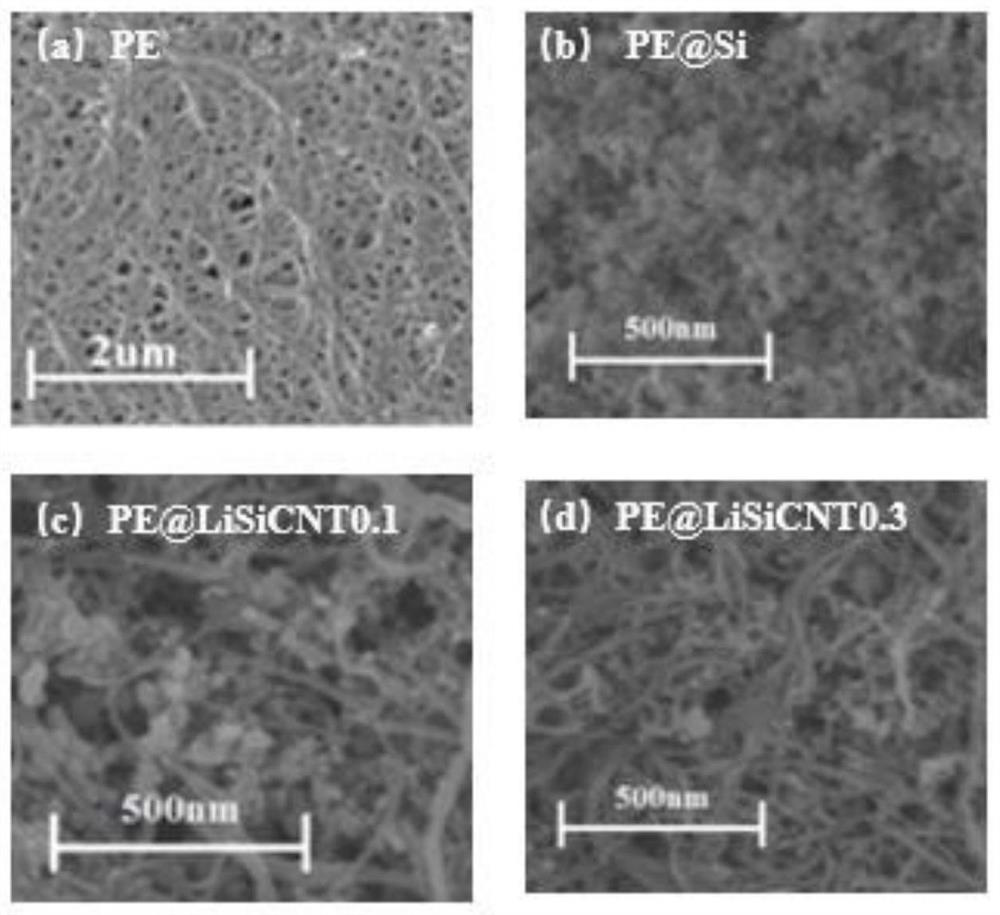

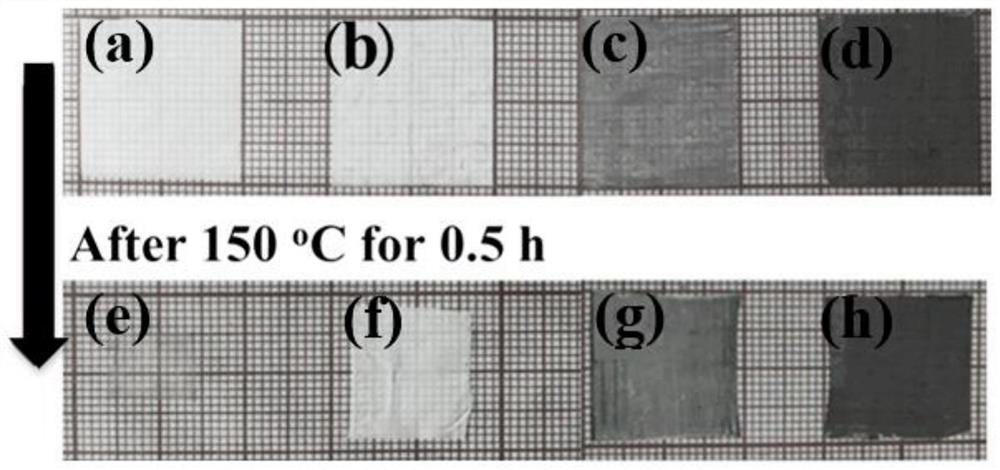

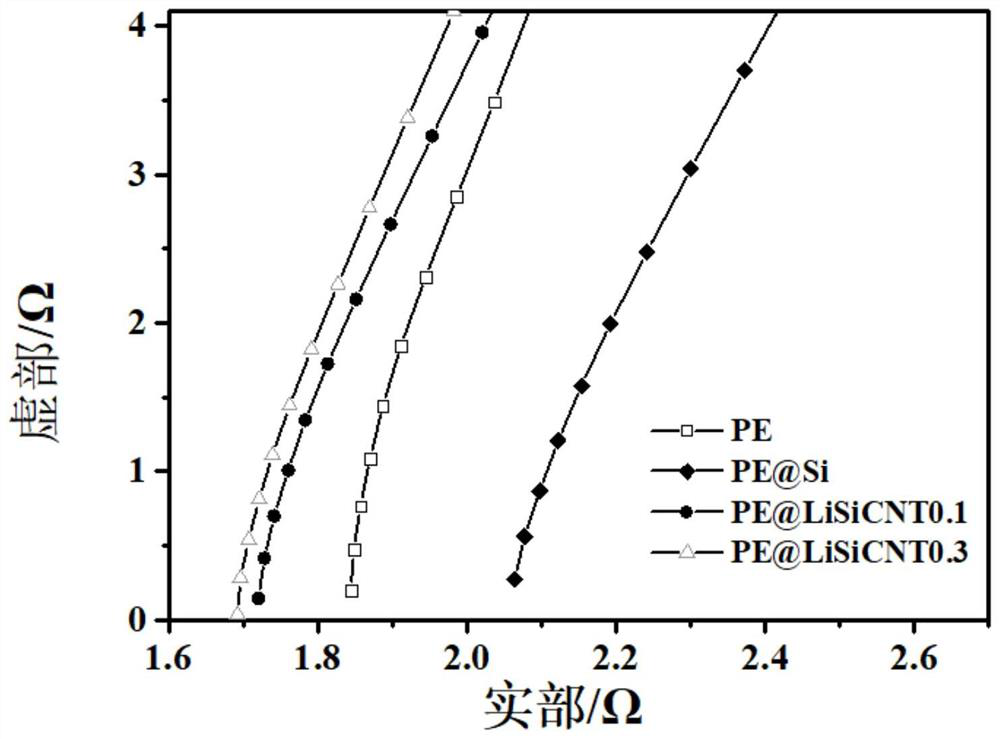

[0037] 4g of polyvinyl alcohol (PVA) and 96ml of deionized water were added to a three-necked flask, and stirred at 90°C for 4 hours under reflux to obtain a 4% mass concentration PVA aqueous solution. Mix water-based hydroxylated carbon nanotubes (CNT-OH) and deionized water to form a 5% CNT-OH solution. 1g nano SiO 2 And 0.3 g of 5% CNT-OH solution were added to 13.7 g of PVA aqueous solution, ultrasonicated and stirred for 0.5 h to obtain a coating solution with a CNT-OH content of 0.1%.

[0038] (2) Lithium salt modified polyolefin diaphragm:

[0039] Lithium bis(trifluoromethylsulfonyl)imide (LiTFSI) was added to ethanol to prepare a LiTFSI / ethanol solution with a mass concentration of 2%. The PE diaphragm was first ultrasonically cleaned with ethanol, then dried in a vacuum at 40°C and placed in LiTFSI / Soaking in ethanol solution for 30 minutes, and vacuum drying at 40°C for 24 hours to obtain lithium salt modified polyolefin membr...

Embodiment 2

[0047] (1) Preparation of coating liquid:

[0048] Place 4g PVA and 96ml deionized water in a three-necked flask, reflux and stir at 90°C for 4h to obtain a 4% mass concentration PVA aqueous solution. Mix the aqueous CNT-OH and deionized water into a 5% CNT-OH solution. 1g nano SiO 2 Adding 0.9 g of 5% CNT-OH solution into 13.1 g of PVA aqueous solution, ultrasonic and stirring for 0.5 h to obtain a coating solution with a CNT-OH content of 0.3%.

[0049] (2) Lithium salt modified polyolefin diaphragm:

[0050] Lithium bis(trifluoromethylsulfonyl)imide (LiTFSI) was added to ethanol to prepare a LiTFSI / ethanol solution with a mass concentration of 2%. The PE diaphragm was ultrasonically cleaned with ethanol, dried in a vacuum at 40°C and placed in the LiTFSI / ethanol solution Soaked in medium for 30min, and dried in vacuum at 40℃ for 24h to obtain lithium salt modified polyolefin membrane.

[0051] (3) Preparation of PE@LiSiCNT0.3 composite membrane:

[0052] Spread the lithium salt-mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance value | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com