Method for treating phosphate radicals in water body by utilizing Bi-MOF-polymer compound

A technology of polymers and composites, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of low phosphate adsorption capacity and difficult recovery, and achieve broad industrial application prospects and economic efficiency Good, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

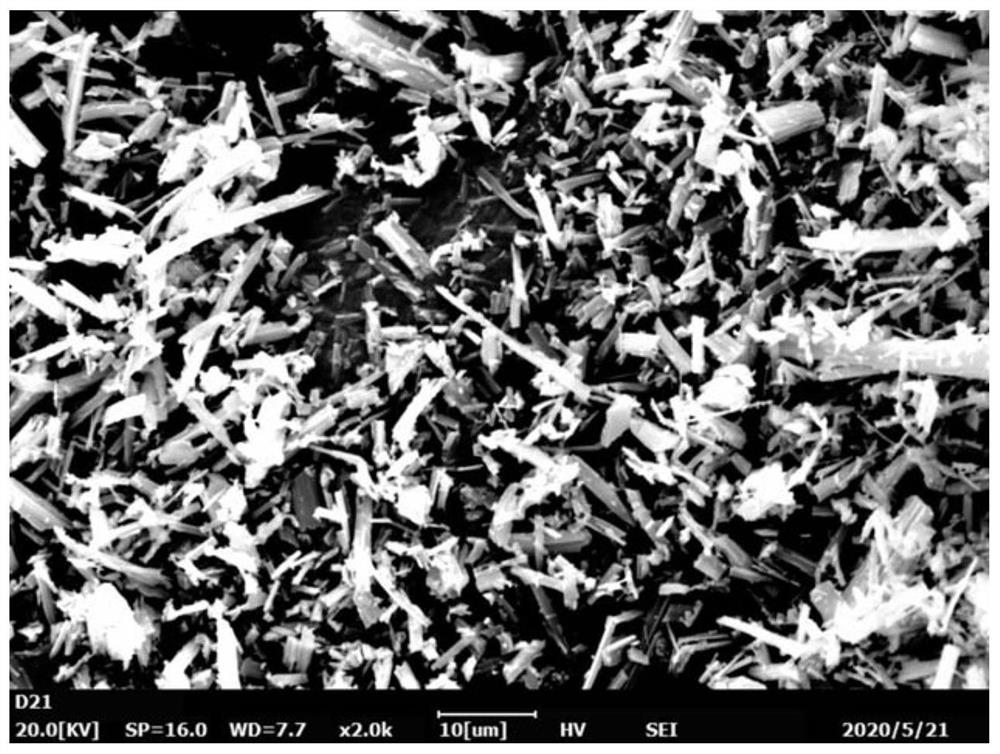

Image

Examples

Embodiment 1

[0023] 3mmol trimesic acid (H 3 BTC) was dissolved in 30ml methanol (MeOH) solution, while 1mmol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) Dissolve in 30ml N after grinding, in N-dimethylformamide (DMF), after fully dissolving respectively, mix the two evenly to obtain Bi 3+ -H 3 BTC mixed solution.

[0024] The mixed solution was transferred to a 100ml reaction kettle, placed in a constant temperature oven and heated to 125°C, and the reaction time was 24h to obtain product A;

[0025] The above product A was repeatedly filtered and washed with anhydrous methanol and N,N-dimethylformamide, and dried at 65°C to obtain the final product Bi-MOF;

[0026] Put 1 g of Bi-MOF in 10% polyacrylonitrile (PAN) solution (1 g polyacrylonitrile, 9 g N, N-dimethylformamide), stir for 1 h to make it uniform, and then freeze-dry for 24 h to obtain Bi- MOF / PAN composite;

[0027] The above-mentioned adsorbent Bi-MOF / PAN composite was used in the phosphate adsorption experiment,...

Embodiment 2

[0029] 3 mmol of 2,6-pyridinedicarboxylic acid and 1 mmol of bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) be dissolved in 30ml methanol (MeOH) solution respectively, accelerate its homogeneous dispersion by supersonic treatment respectively for 20 minutes, then both are mixed homogeneously, obtain Bi 3+ -H 3 BTC mixed solution.

[0030] The mixed solution was transferred to a 100ml reaction kettle, placed in a constant temperature oven and heated to 125°C, and the reaction time was 24h to obtain product A;

[0031] The above product A was repeatedly filtered and washed with anhydrous methanol, and dried at 65°C to obtain the final product Bi-MOF;

[0032]Bi-MOF1g was placed in 20% polyvinylidene fluoride (PVDF) solution (2g polyacrylonitrile, 8g N, N-dimethylacetamide), stirred for 1h to make it uniform, and then vacuum dried for 24h to obtain Bi- MOF / PVDF composite;

[0033] The above-mentioned adsorbent Bi-MOF / PVDF composite was used in the phosphate adsorption e...

Embodiment 3

[0035] Put the Bi-MOF / PAN composite in Example 1 into the natural water body polluted by phosphate, wherein the test water body found that the chloride ion content was 96mg / L, the sulfate content was 25mg / L, and the phosphate content was 21mg / L, the total organic carbon content is 27mg / L; by putting 20g Bi-MOF / PAN composite into 100mL of the natural water body, after stirring and adsorption, the separation test found that the adsorption amount of phosphate was 39mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com