Preparation method of ethyl p-aminobenzoate

A technology of ethyl aminobenzoate and p-nitrobenzoic acid, which is applied in the field of preparation of ethyl aminobenzoate, can solve the problems of unsuitable publicity and opening of student experiments, high raw material prices, and difficult separation, and achieve high cost performance and high product quality. Good quality, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of ethyl p-aminobenzoate, comprising the steps of:

[0034] (1) p-Nitrobenzoic acid, ethanol, composite catalyst are dropped in the reactor;

[0035] (2) Reaction for 7 hours under reflux conditions to obtain ethyl p-aminobenzoate, intermediate p-aminobenzoic acid, and unreacted complete p-nitrobenzoic acid;

[0036] (3) The catalyst was filtered out, and the filtered catalyst was washed with ethanol at 50° C. and used for the next batch of reactions. ;

[0037] (4) excess ethanol is removed from the reaction solution, and the residue is dissolved in toluene to obtain a toluene reaction solution;

[0038] (5) the toluene reaction solution is washed with alkali and washed with water, and left to stand for stratification to obtain a toluene layer and an alkaline water layer;

[0039] (6) the toluene layer obtains ethyl p-aminobenzoate through cooling, crystallization, and centrifugation, and obtains the finished product of ethyl p-aminobenzoate aft...

Embodiment 2-6

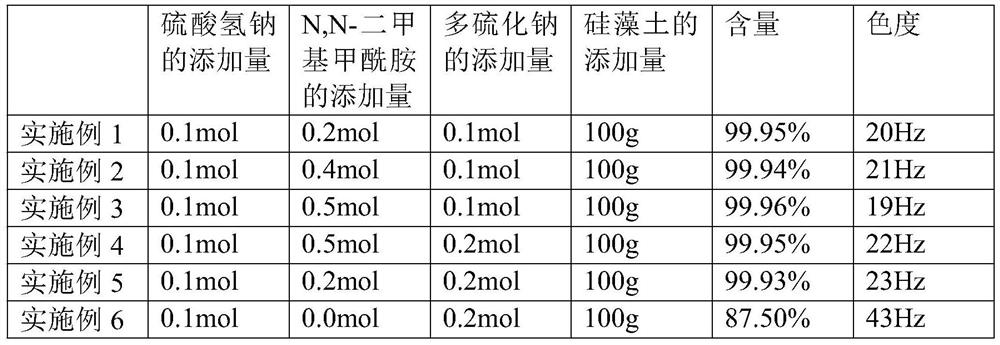

[0047] Embodiment 2-6 (following embodiment is used for researching the impact of composite catalyst on product)

[0048] Others are all the same as in Example 1, except that the composite catalyst is different, and the details are as follows:

[0049] The influence of table 1 composite catalyst on product

[0050]

Embodiment 7-11

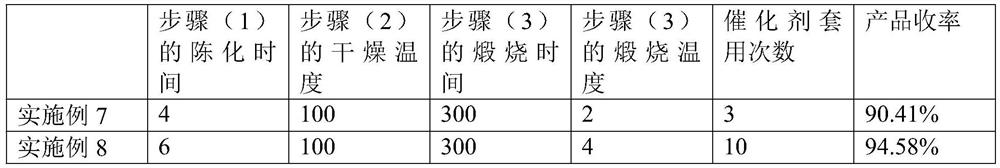

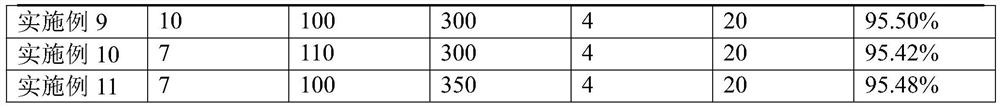

[0051] Embodiment 7-11 (following embodiment is used for researching the impact of composite catalyst preparation method on product)

[0052] Others are all the same as in Example 1, except that the preparation method of the composite catalyst is different, and the details are as follows:

[0053] Table 1 The impact of the composite catalyst preparation method on the product

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com