Preparation method of urushiol-based environment-friendly wood wax oil

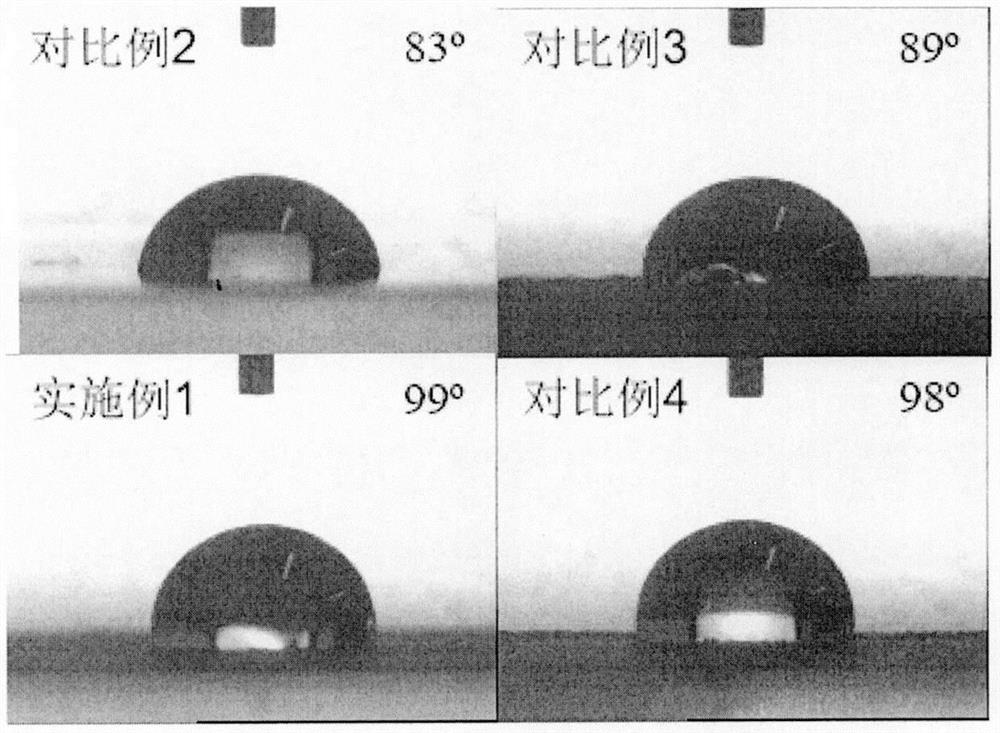

An environmentally friendly, wood wax oil technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of poor alkali resistance, long drying time, high viscosity, etc., to improve impact resistance and flexibility, and improve water resistance Performance, bright and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 is the best embodiment

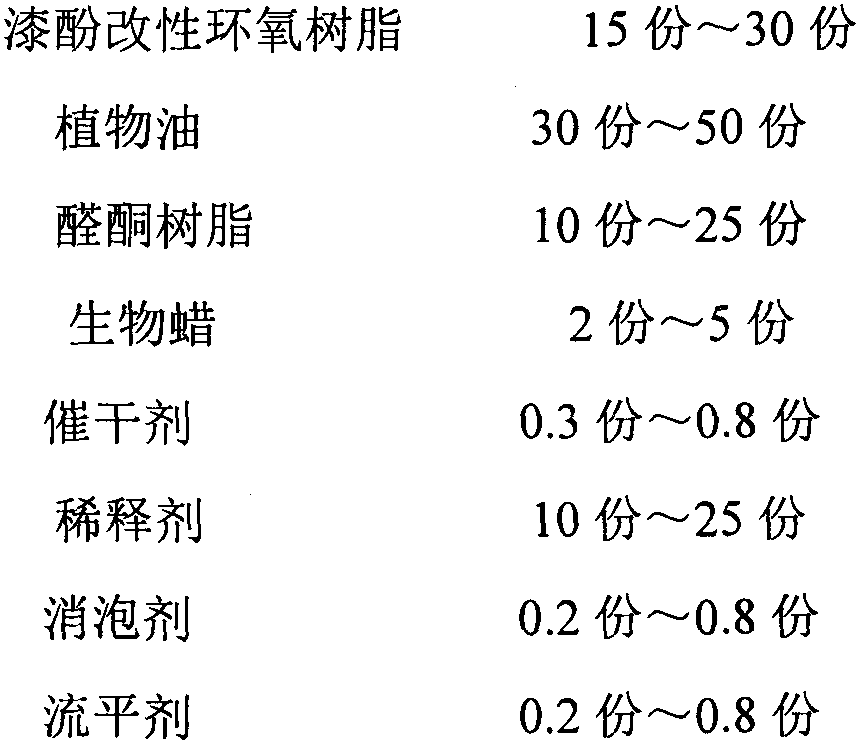

[0030] A kind of urushiol base environment-friendly type wood wax oil, it comprises the raw material of following parts by weight:

[0031] 30 parts of urushiol glycidyl ether, 15 parts of cooked tung oil, 15 parts of linseed oil, 20 parts of aldehyde and ketone resin, 1.5 parts of refined lacquer wax, 1.5 parts of carnauba wax, 0.35 parts of rare earth isooctanoate, 0.15 parts of cobalt isooctanoate, 15 parts of turpentine 0.5 parts, 0.5 parts of defoamer, 0.5 parts of leveling agent, 0.5 parts of butanone oxime.

[0032] The preparation method of above-mentioned urushiol-based environment-friendly wood wax oil comprises the following steps:

[0033] Step 1: Add 30 parts of urushiol, 90 parts of epichlorohydrin and 0.6 parts of catalyst into a four-necked flask equipped with a condensation reflux device, a stirrer, and a thermometer, then heat to 80° C., and stir for 4 hours. Cool to room temperature, and filter under reduced pre...

Embodiment 2

[0038] A kind of urushiol base environment-friendly type wood wax oil, it comprises the raw material of following parts by weight:

[0039] 24 parts of urushiol glycidyl ether, 18 parts of cooked tung oil, 18 parts of linseed oil, 20 parts of aldehyde and ketone resin, 2 parts of beeswax, 1 part of carnauba wax, 0.35 parts of rare earth isooctanoate, 0.15 parts of cobalt isooctanoate, 15 parts of citrus oil , 0.5 parts of defoamer, 0.5 parts of leveling agent, and 0.5 parts of butanone oxime.

[0040] The preparation method of above-mentioned urushiol-based environment-friendly wood wax oil comprises the following steps:

[0041] Step 1: Add 25 parts of urushiol, 75 parts of epichlorohydrin and 0.5 part of catalyst into a four-necked flask equipped with a condensation reflux device, a stirrer, and a thermometer, then heat to 80° C., and stir for 4 hours. Cool to room temperature, and filter under reduced pressure to obtain dark brown urushiol glycidyl ether.

[0042] Step 2:...

Embodiment 3

[0046] A kind of urushiol base environment-friendly type wood wax oil, it comprises the raw material of following parts by weight:

[0047] 36 parts of urushiol glycidyl ether, 12 parts of cooked tung oil, 12 parts of linseed oil, 20 parts of aldehyde and ketone resin, 2 parts of refined lacquer wax, 1 part of carnauba wax, 0.25 parts of rare earth isooctanoate, 0.25 parts of cobalt isooctanoate, citrus oil 15 parts, 0.5 parts of defoamer, 0.5 parts of leveling agent, 0.5 parts of butanone oxime.

[0048] The preparation method of above-mentioned urushiol-based environment-friendly wood wax oil comprises the following steps:

[0049] Step 1: Add 36 parts of urushiol, 108 parts of epichlorohydrin and 0.72 parts of catalyst into a four-necked flask equipped with a condensation reflux device, a stirrer, and a thermometer, then heat to 80° C., and stir for 4 hours. Cool to room temperature, and filter under reduced pressure to obtain dark brown urushiol glycidyl ether.

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com