High-strength high-hardness epoxy modified MS sealant and preparation method thereof

A MS sealant and epoxy modification technology, applied in chemical instruments and methods, adhesives, and other chemical processes, can solve the problems of poor weather resistance of sealants, high equipment requirements, and easy adsorption of dust, etc., to increase water resistance properties, high cross-linking density, and increased bulk strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

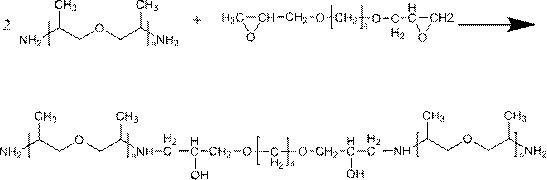

Method used

Image

Examples

Embodiment 1

[0023] A high-strength and high-hardness epoxy-modified MS sealant, firstly prepare a silane-modified polyether polymer, add 495 parts of difunctional polyetheramine with a molecular weight of 1000 into a dry 2L reaction kettle, and seal the reaction kettle , replace the air in the reactor with dry nitrogen for 3 times, start stirring, and slowly raise the temperature to 50-60°C; slowly add 100 parts of 1,4-butanediol diglycidyl ether dropwise for addition reaction, and control the reaction temperature at 50-60°C for 2 hours; then slowly add 128 parts of 3-glycidyloxypropyltrimethoxysilane dropwise, and control the reaction temperature at 70-90°C for 3 hours; slowly add 15 parts of DMP-30 to control the reaction temperature Reaction at 70-90°C for 15 minutes; vacuum degassing for 15 minutes at a pressure of ≥-0.09MPa to obtain a colorless and transparent epoxy resin-blocked silane-modified polyether polymer.

[0024] Add 700 parts of the above-mentioned silane-modified polyeth...

Embodiment 2

[0026] A high-strength and high-hardness epoxy-modified MS sealant. First, prepare a silane-modified polyether polymer. Add 990 parts of difunctional polyetheramine with a molecular weight of 2000 into a dry 2L reactor, and seal the reactor. , replace the air in the reactor with dry nitrogen for 3 times, start stirring, and slowly raise the temperature to 50-60°C; slowly add 100 parts of polypropylene glycol diglycidyl ether dropwise for addition reaction, and control the reaction temperature at 50-60°C, It lasted 2 hours; then slowly added 123 parts of 3-glycidyloxypropyltrimethoxysilane dropwise, and the reaction temperature was controlled at 70-90°C, which lasted 3 hours; slowly added 40 parts of DMP-30 to control the reaction temperature at 70-90°C ; Reaction for 15 minutes; Vacuum degassing for 15 minutes under a pressure of ≥-0.09MPa to obtain a colorless and transparent epoxy resin-blocked silane-modified polyether polymer.

[0027] Add 700 parts of the above-mentioned ...

Embodiment 3

[0029] A high-strength and high-hardness epoxy-modified MS sealant, firstly prepare a silane-modified polyether polymer, add 1500 parts of difunctional polyetheramine with a molecular weight of 3000 into a dry 2L reaction kettle, and seal the reaction kettle , replace the air in the reactor with dry nitrogen for 3 times, start stirring, and slowly raise the temperature to 50-60°C; slowly add 100 parts of ethylene glycol diglycidyl ether dropwise for addition reaction, and control the reaction temperature at 50-60°C , lasted 2h; then slowly added 122 parts of 3-glycidyloxypropyltrimethoxysilane dropwise, the reaction temperature was controlled at 70-90°C, and lasted 3h; slowly added 60 parts of DMP-30 to control the reaction temperature at 70-90 ℃; reaction for 15 minutes; vacuum degassing for 15 minutes under a pressure ≥ -0.09MPa to obtain a colorless and transparent epoxy resin-blocked silane-modified polyether polymer.

[0030]Add 700 parts of the above-mentioned silane-mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com