Metal alkoxide, and aqueous resin crosslinking composition and aqueous resin composition using the same

A metal alkoxide and water-based resin technology, which is applied in the field of cross-linking agent compositions for water-based resins and water-based resin compositions, can solve the problems of water resistance and durability degradation, and achieve excellent hydrolysis resistance and excellent cross-linking reactivity , Improve the effect of cross-linking reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the metal alkoxide (X) is not particularly limited, for example, by using commercially available titanium tetraoxide, zirconium tetraoxide or aluminum trioxide as a raw material of a metal alkoxide of a lower alcohol having 1 to 4 carbon atoms, the Each alkoxy group of these metal alkoxides is obtained by performing a substitution reaction of all the alkoxy groups by a known method using a specific polyalkylene glycol monohydrocarbyl ether.

[0056] (Metal alkoxide (Y))

[0057] The metal alkoxide (Y) of the second aspect of the present invention is represented by the following formula (2-1), (2-2) or (2-3), and is a compound having a mass average molecular weight of 600-6000.

[0058] Ti(OA) p (OR) 4-p (2-1)

[0059] Zr(OA) q (OR) 4-q (2-2)

[0060] Al(OA) r (OR) 3-r (2-3)

[0061] The metal atom constituting the metal alkoxide (Y) is also a titanium atom, a zirconium atom, or an aluminum atom as in the metal alkoxide (X).

[0062...

Embodiment

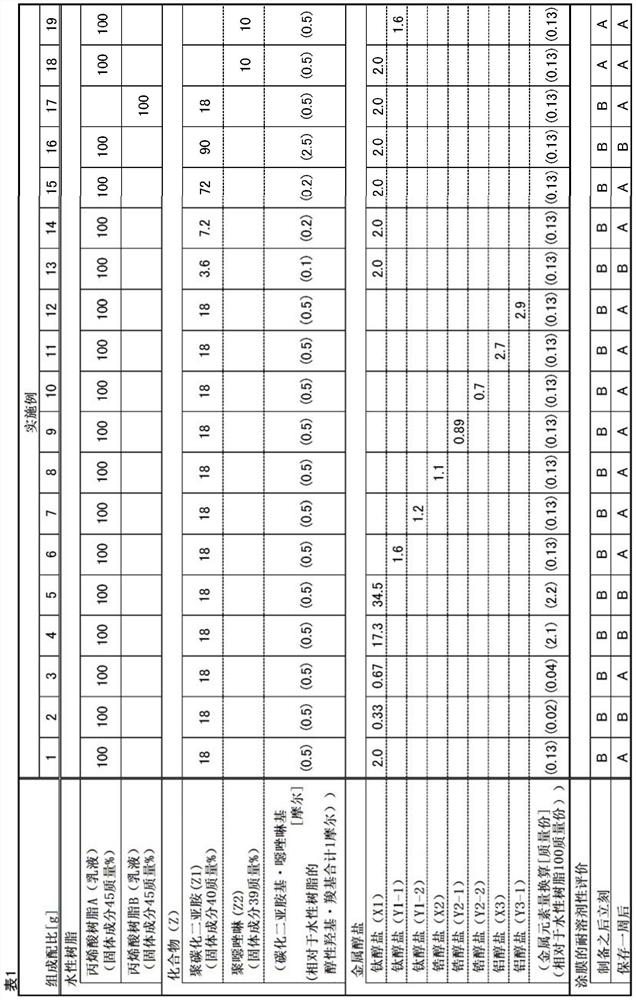

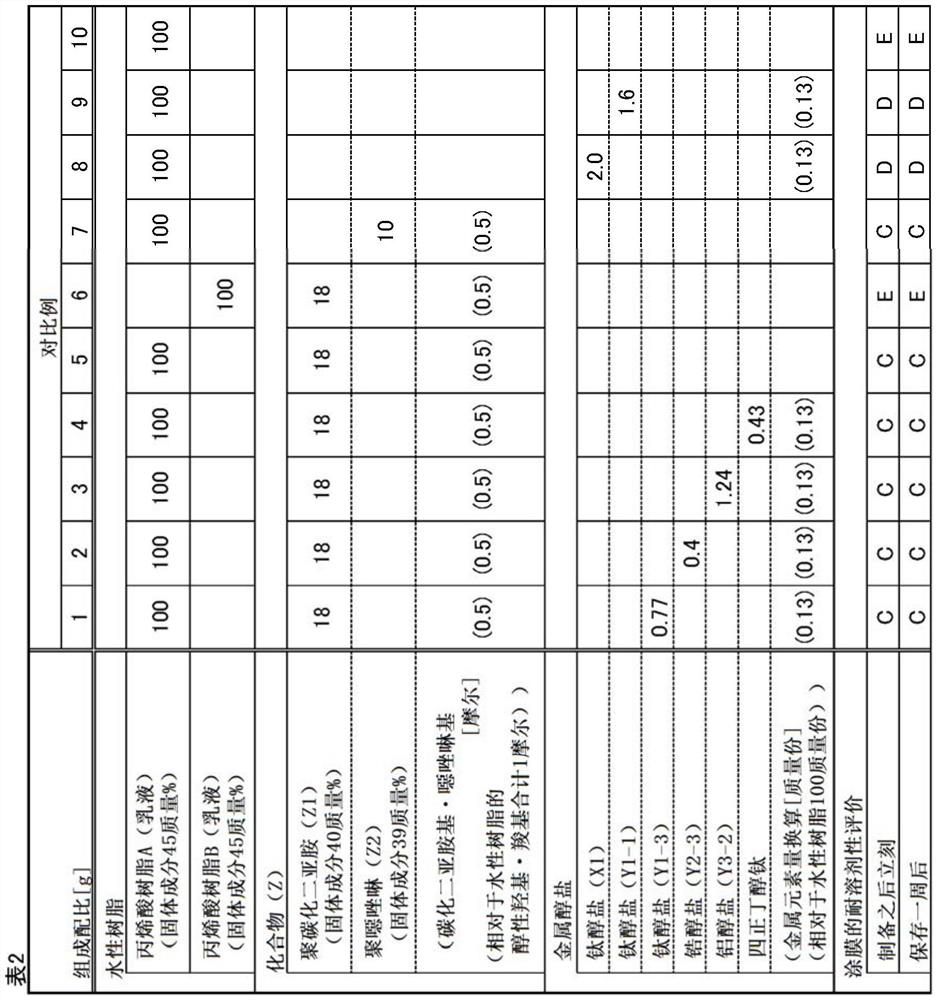

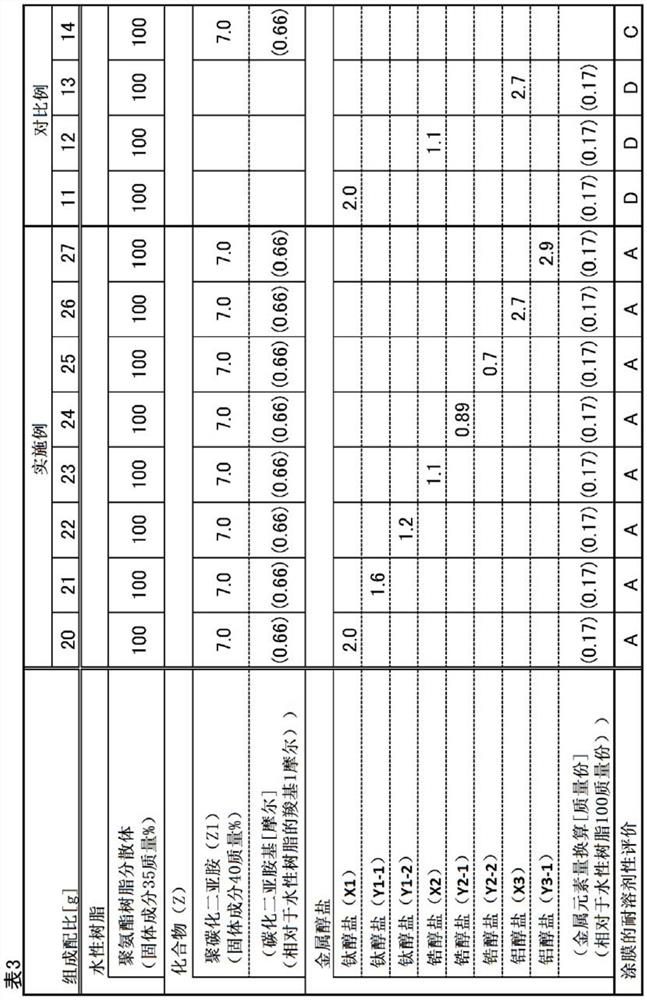

[0120] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to this.

[0121] The details of the blended raw materials in the preparation of the water-based resin compositions of the following examples, comparative examples and synthesis examples are as follows. In addition, in the following water-based resins, the hydroxyl value is a value based on an alcoholic hydroxyl group, and the acid value is a value based on a carboxyl group.

[0122]

[0123] Acrylic resin A (emulsion): "NeoCryl (registered trademark) XK-103", manufactured by DSM Coating Resins; solid content (resin content) 45% by mass, dispersion medium: water, hydroxyl value (solid content conversion) 47.2 mgKOH / g, acid value (solid content conversion) 3.2mgKOH / g

[0124] Acrylic resin B (emulsion): "BURNOCK (registered trademark) WE-304", manufactured by DIC Corporation; solid content (resin content) 45% by mass, dispersion medium: water, hydroxyl value (solid c...

Synthetic example P

[0142] (Synthesis Example P) Synthesis of Polycarbodiimide

[0143]Put 1572 g of dicyclohexylmethane-4,4'-diisocyanate and 7.86 g of 3-methyl-1-phenyl-2-phosphole-1-oxide as a carbodiimidation catalyst into the belt In a 3000-ml reaction vessel equipped with a reflux tube and a stirrer, stirring was carried out at 185° C. for 10 hours under a nitrogen flow to obtain an isocyanate-terminated polycarbodiimide which is a polymer of dicyclohexylmethane-4,4′-diisocyanate.

[0144] A toluene solution of di-n-butylamine having a known concentration was mixed with this isocyanate-terminated polycarbodiimide to react the terminal isocyanate group with di-n-butylamine. The remaining di-n-butylamine was neutralized and titrated with hydrochloric acid standard solution, and the residual amount of isocyanate group [mass %] was calculated by potentiometric titration (device used: automatic titration device "COM-900", manufactured by Hiranuma Sangyo Co., Ltd.) isocyanate group), the result ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com